Compound energy-saving type medical molecular sieve central oxygen generation and medical air compression integrated device

A compressed air and molecular sieve technology, which is applied in oxygen preparation and respirators, etc., can solve the problems of air supply safety, reliability and effectiveness reduction, uninterrupted air supply process, hospital gas fluctuations, etc., to reduce after-sales service The effect of reducing the number of times, reducing energy consumption, and reducing mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

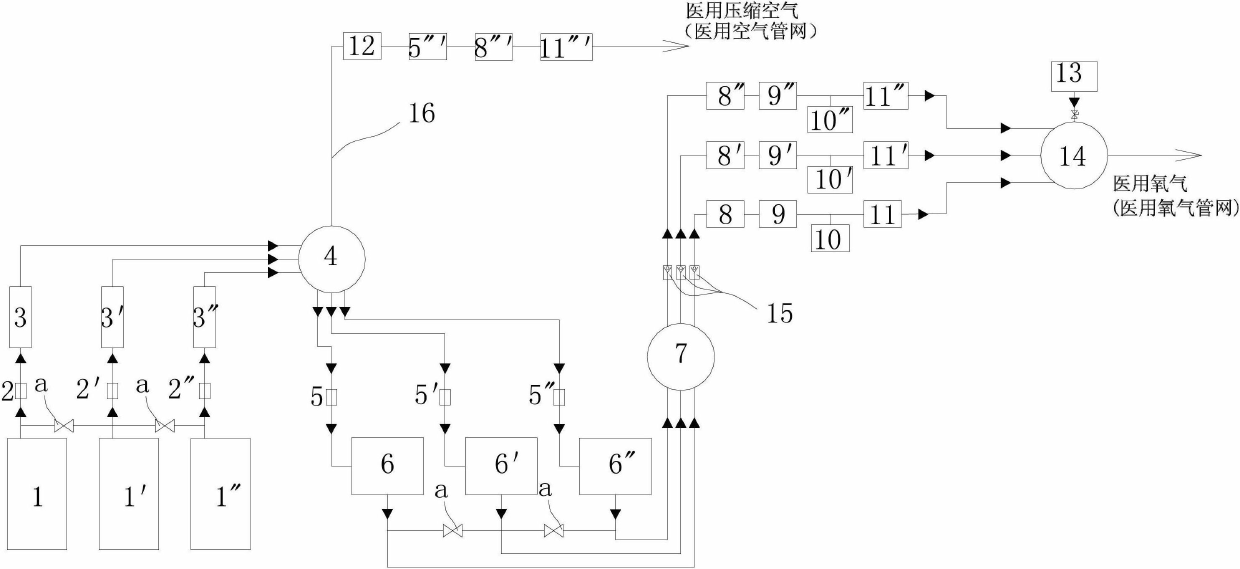

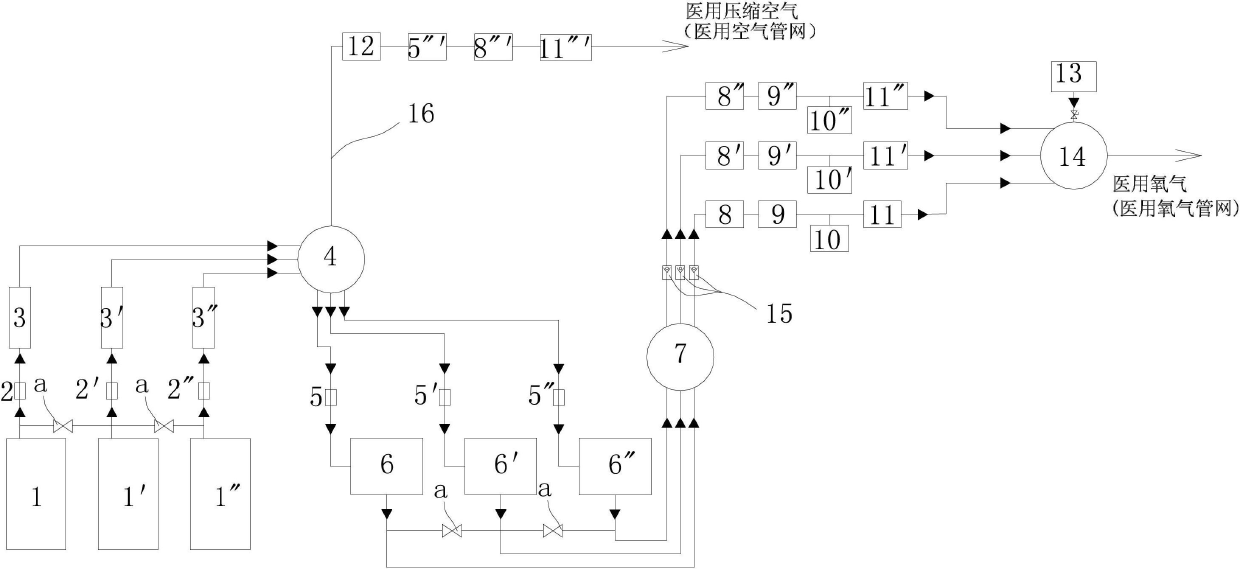

[0028] Such as figure 1 As shown, the composite energy-saving medical molecular sieve central oxygen production and medical compressed air integrated equipment, including the main air supply source, auxiliary air supply source and backup air supply source that continues to supply oxygen after the main air supply source and auxiliary air supply source are shut down at the same time , the main air supply source, the auxiliary air supply source and the backup air supply source respectively share an air balance tank 4, an oxygen balance tank 7 and an oxygen sub-cylinder 14 with pressure and flow equalization functions, and the auxiliary air supply sources are arranged side by side on the main supply Next to the air source and auxiliary supplementary air supply to the main air supply source; the main air supply source includes the main air compressor 1, the main main road filter 2, the main cold dryer 3, the main oxygen generator 6, and the main oxygen flow measuring device 9 and t...

Embodiment 2

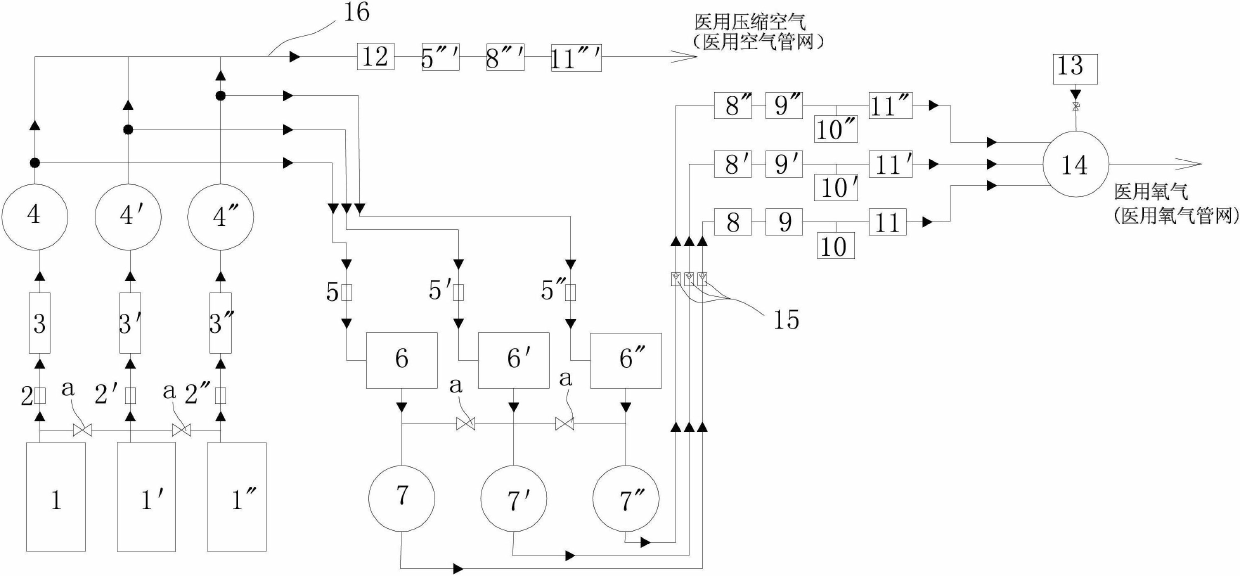

[0038] The only difference between Embodiment 2 and Embodiment 1 is that, as figure 2 As shown, each pipeline of the main air supply source, auxiliary air supply source and backup air supply source is separately connected to an air balance tank (4, 4′, 4″) and an oxygen balance tank (7, 7′, 7″ ), the other output end of each air balance tank (4, 4', 4 ") is connected in parallel and then connected to the medical air pipeline 16 to ensure that the main air supply source, auxiliary air supply source and backup air supply source are mutually They are independent, do not interfere with each other, and supply gas separately. Others are the same as those in Embodiment 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com