Laser heating rivetless riveting device

A technology of rivetless riveting and laser heating, applied in the field of rivetless riveting device and laser heating rivetless riveting device, can solve the problems of reducing deformation resistance, material breaking, reducing riveting force, frame rigidity, etc., to reduce deformation resistance , good quality, the effect of improving plastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention. Detailed implementation modes and specific operation procedures are given. However, the protection scope of the present invention is not limited to the following embodiments. .

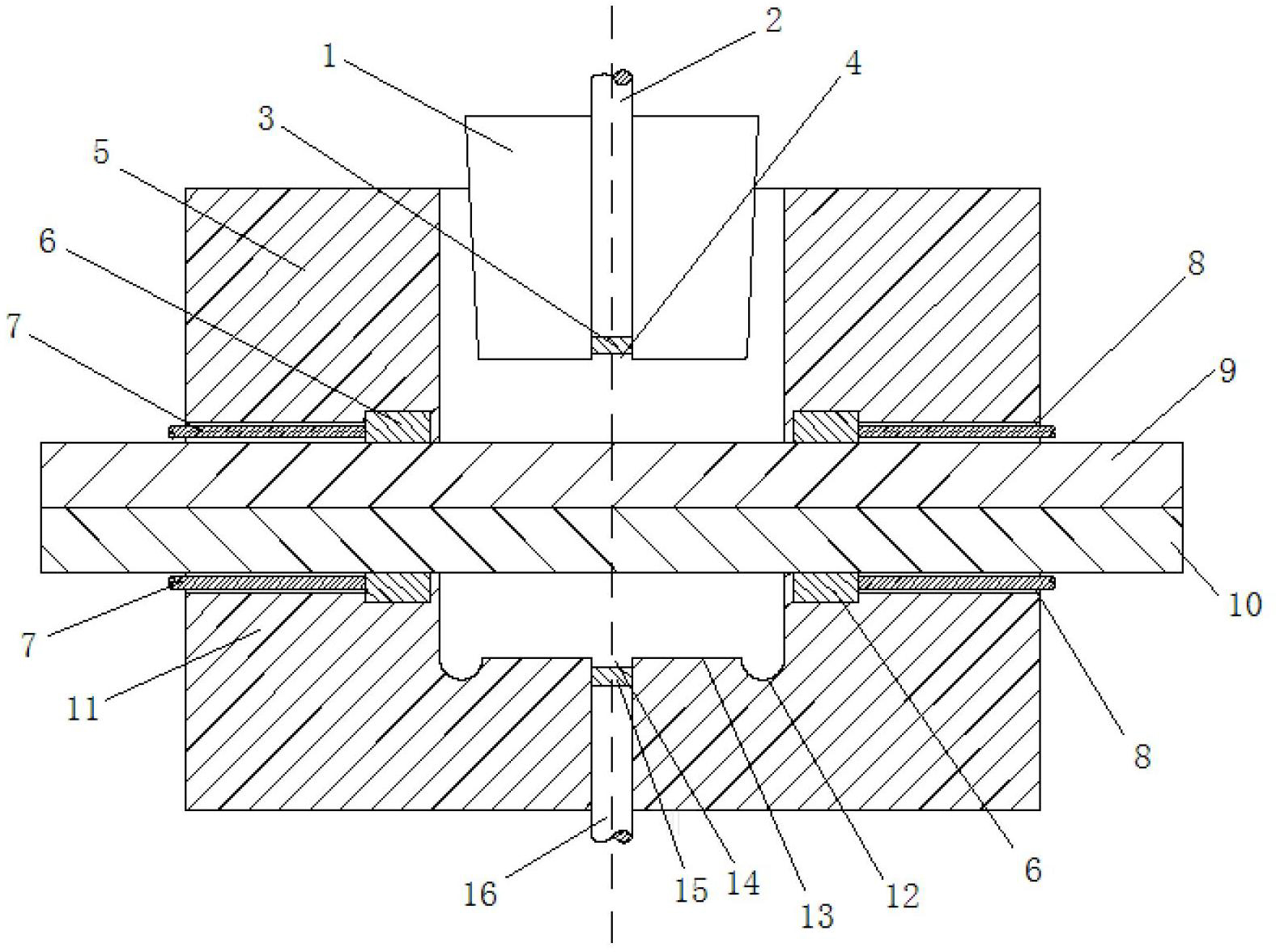

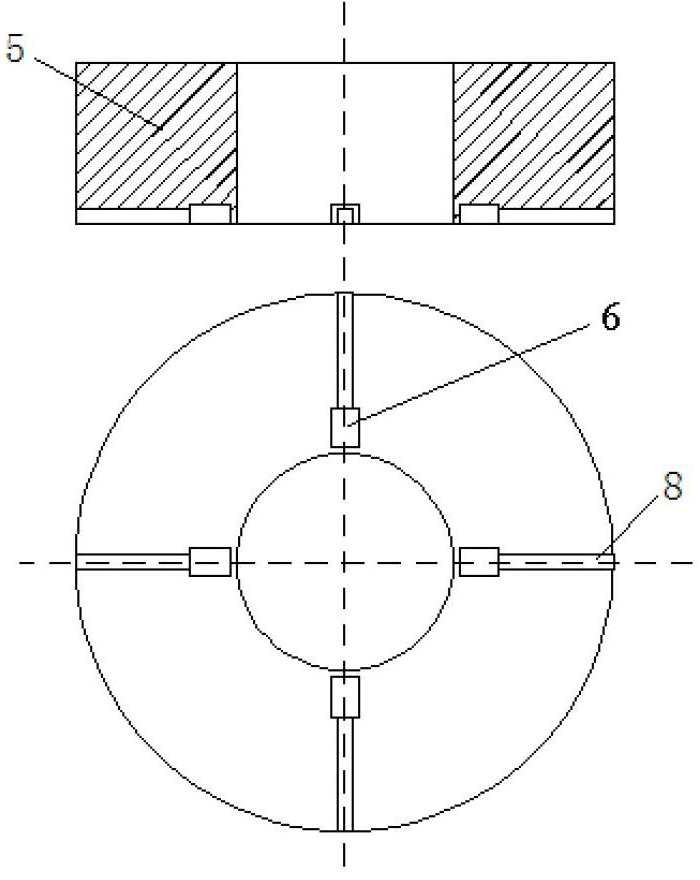

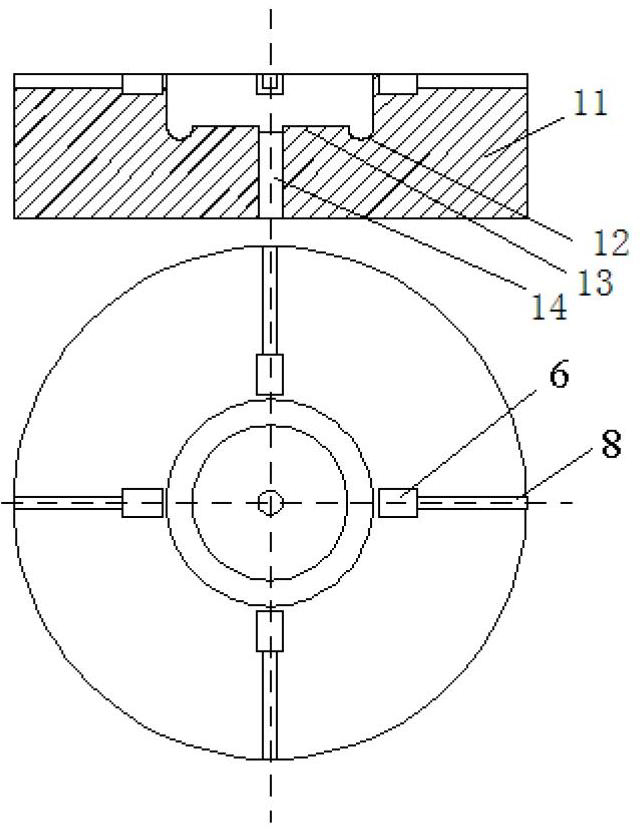

[0023] The invention includes a composite punch (1), a composite blank holder (5), a composite die (11) and a laser emission control part. The composite punch (1) is sleeved in the composite blank holder (5), and is arranged coaxially with the upper and lower plates (9), (10) and the composite die (11) from top to bottom.

[0024] The composite punch (1) has a round table structure with a hollow hole I (4) in the center. The diameter of the lower surface of the composite punch (1) is smaller than the diameter of the upper surface, and the outer surface of the composite punch (1) is provided with a certain draft angle A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com