Fragment-free metal arched rupture disk with crossed slot, production device and manufacturing method thereof

A technology for producing devices and bursting discs, applied in valve devices, functional valve types, safety valves, etc., can solve the problems of high processing cost of the tire, affecting the discharge, asymmetry at the intermediate discontinuity, etc., to increase the stress corrosion resistance of the product. performance, preventing edge twitching, and eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

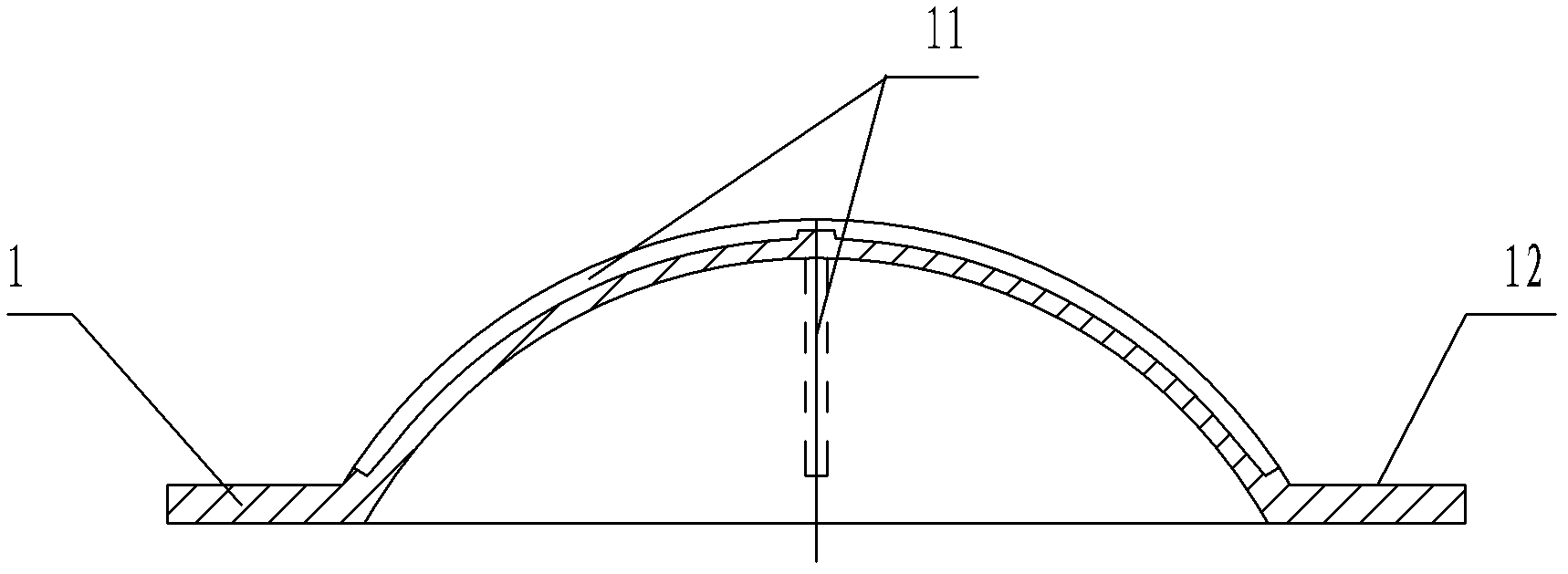

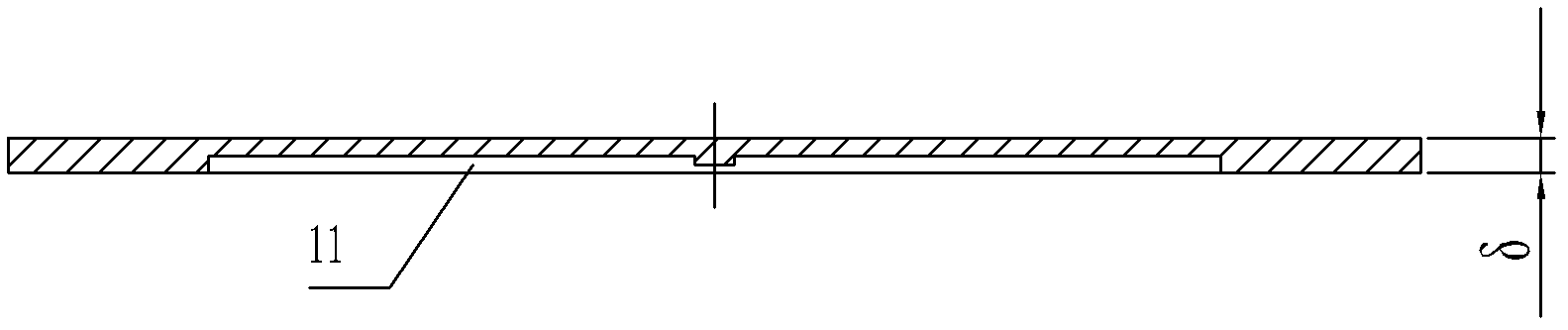

[0054] Processing of the cross-groove non-fragmented metal positive arch bursting disc: take a circular blank, the material is stainless steel (316L), the thickness of the blank is 0.4mm, and the discharge diameter is 100mm; after the blank is grooved by the mold 3, It is pre-arched in the pre-arched mold 4, and the height of the arch surface is 12 mm. After pre-arching, the stress is relieved at low temperature. The annealing temperature is 240 ° C, and the holding time is 30 minutes. The bursting pressure of the bursting disc is 3.0 MPa, and the bursting temperature is 22 ° C. .

Embodiment 2

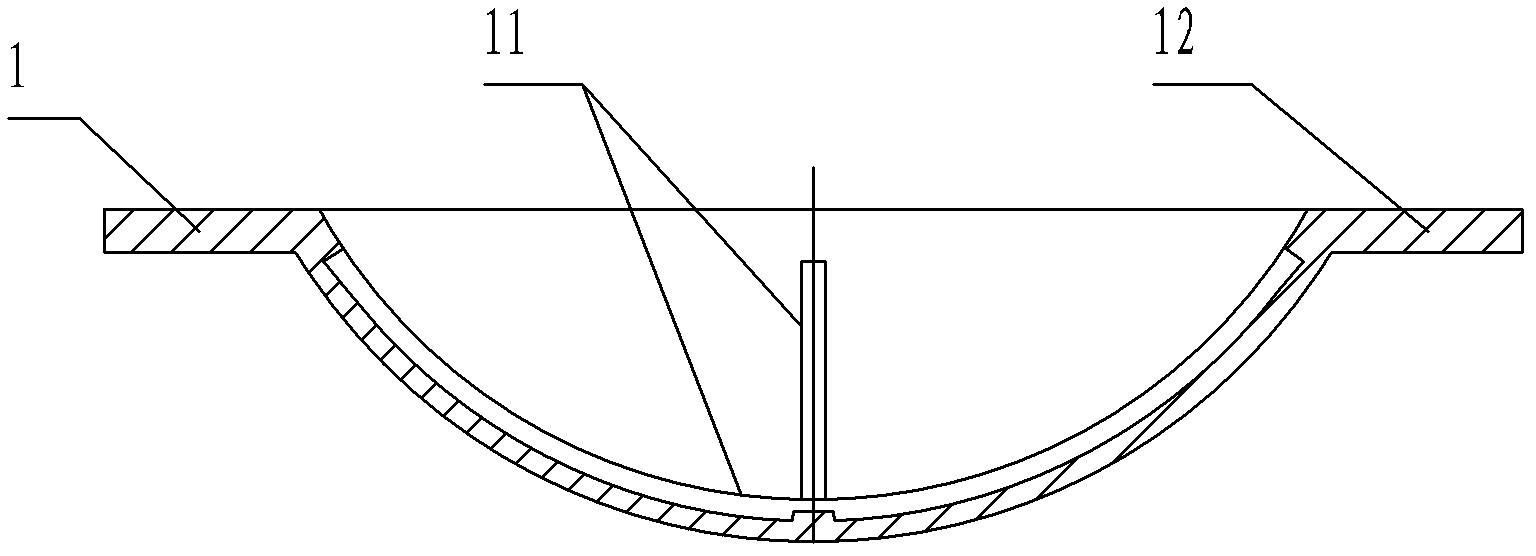

[0056] Processing of cross-groove fragment-free metal anti-arch bursting disc: take a circular blank, material stainless steel (316L), blank thickness is 0.6mm, discharge diameter is 100mm; Pre-arching is formed in the pre-arching mold 4, the height of the arch surface after the first pre-arching is 15mm, the first heat treatment temperature is 1080°C, and the heat preservation is 30 minutes; the second pre-arching is performed, and the height of the arching surface after the pre-arching The temperature and holding time of the second heat treatment are the same as those of the first time. The burst pressure of the prepared burst disc is 1.2MPa, and the burst temperature is 120°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com