Preparation method of halogen bismuth oxide catalyst with photocatalytic activity

A photocatalytic activity, bismuth oxyhalide technology, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve the problems of difficulty in controlling the particle size of bismuth oxyhalide, poor uniformity, etc., and achieves a simple and easy production method and mild conditions. , the effect of improving the crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh a certain amount of 0.9701 g (0.002 mol) Bi(NO 3 ) 3 ·5H 2 O dissolved in 15 mL 1.2 mol / L HNO 3 , slowly add it dropwise to the homogeneous solution formed by hexadecyl pyridinium sulfate and NaCl containing the same amount of substances (0.003 mol), satisfying that the ratio of bismuth ions to chloride ions is 1:1.5, drop A large number of white precipitates were produced during the addition process, then the solution was adjusted to the required pH of 7 with 6 mol / L NaOH, and then continued to stir for 1 h, then poured into the reaction kettle, reacted at 170 °C for 17 h, filtered the sample and washed with distilled water Wash with absolute ethanol several times, dry at 50 °C under air condition, and then grind to obtain BiOCl.

Embodiment 2

[0029] Weigh a certain amount of 0.9701 g (0.002 mol) Bi(NO 3 ) 3 ·5H 2 O dissolved in 15 mL 1.2 mol / L HNO 3 , slowly add it dropwise to the homogeneous solution formed by hexadecyl pyridinium sulfate and NaBr containing the same amount of substances (0.003 mol), satisfying that the ratio of bismuth ions to bromide ions is 1:1.5, drop A large number of light yellow precipitates were produced during the addition process, then the solution was adjusted to the required pH of 7 with 6 mol / L NaOH, and then stirred for 1 h, then poured into the reaction kettle, reacted at 170 °C for 17 h, filtered the sample and used BiOBr was obtained by washing with distilled water and absolute ethanol several times, drying at 50 °C under air condition, and then grinding.

Embodiment 3

[0031] Weigh a certain amount of 0.9701 g (0.002 mol) Bi(NO 3 ) 3 ·5H 2 O dissolved in 15 mL 1.2 mol / L HNO 3 , slowly add it dropwise to the homogeneous solution formed by hexadecyl pyridinium sulfate and NaI containing the same amount of substances (0.003 mol), satisfying that the ratio of bismuth ions to iodide ions is 1:1.5, drop A large amount of reddish-brown precipitates were produced during the addition process, then the solution was adjusted to the required pH of 7 with 6 mol / L NaOH, and then stirred for 1 h, then poured into the reaction kettle, reacted at 170 °C for 17 h, filtered the sample and used BiOI was obtained by washing with distilled water and absolute ethanol several times, drying at 50 °C under air condition, and then grinding.

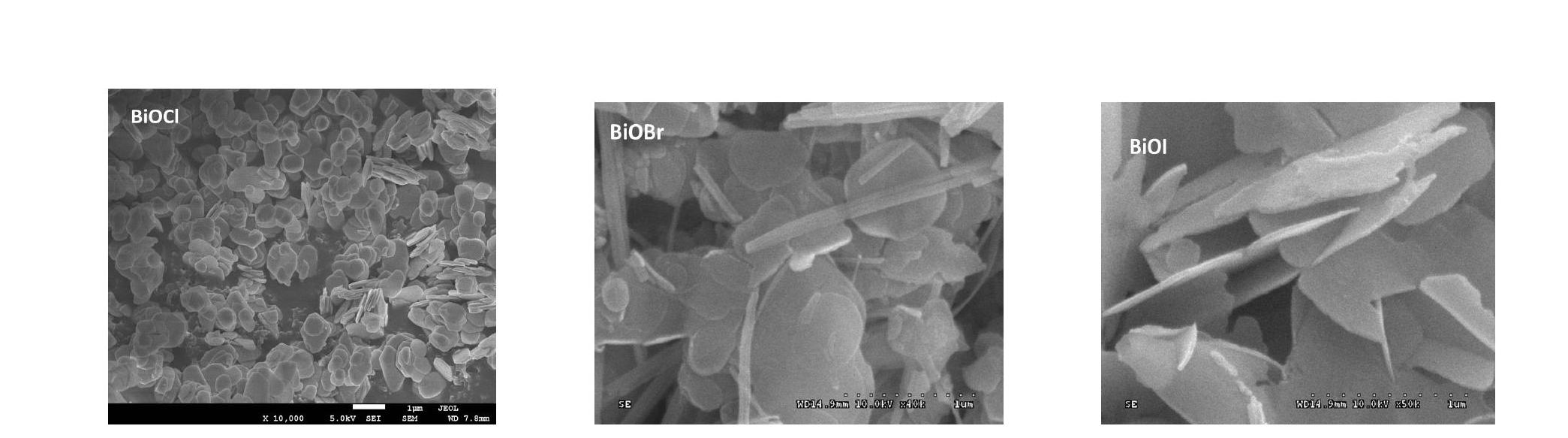

[0032] The BiOCl synthesized by this method is a white solid powder, the BiOBr is a light yellow solid powder, and the BiOI is an orange-red solid powder, all of which have no special smell.

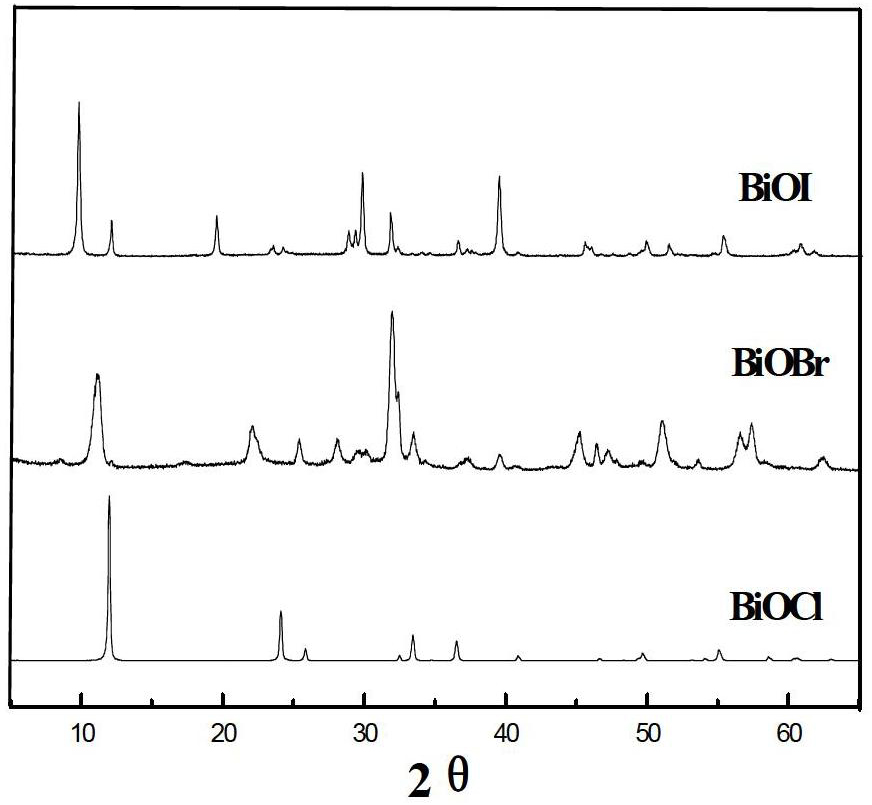

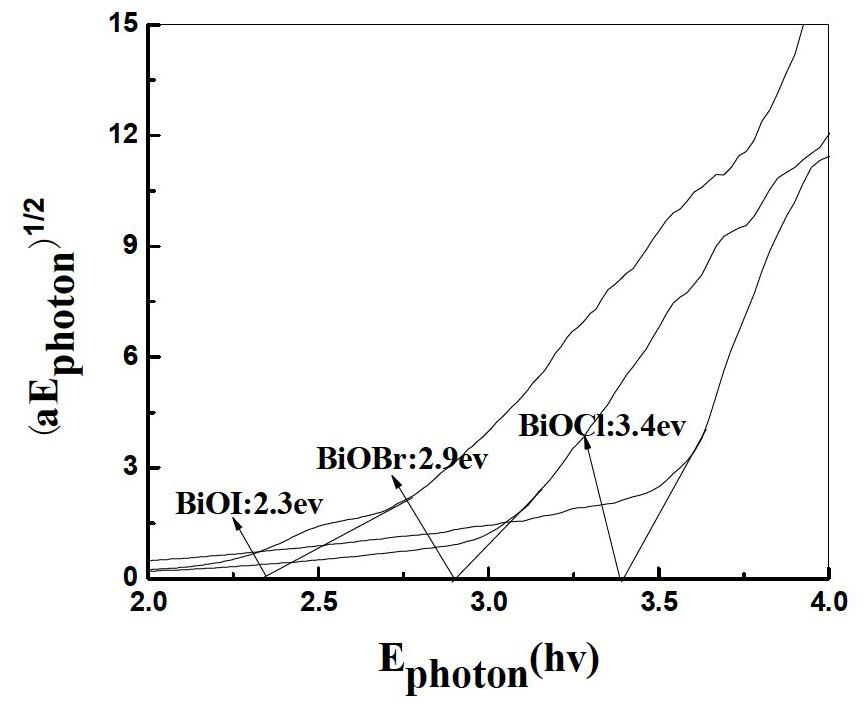

[0033] The XRD (X-ray powder dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com