Defect type UiO-66 photocatalytic material, and preparation method and application thereof

A photocatalytic material, uio-66 technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the lack of catalytic active sites and catalytic performance of MOFs Few reports, high recombination rate and other issues, to achieve high-efficiency photocatalytic activity, increase specific surface area and pore size, and improve photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

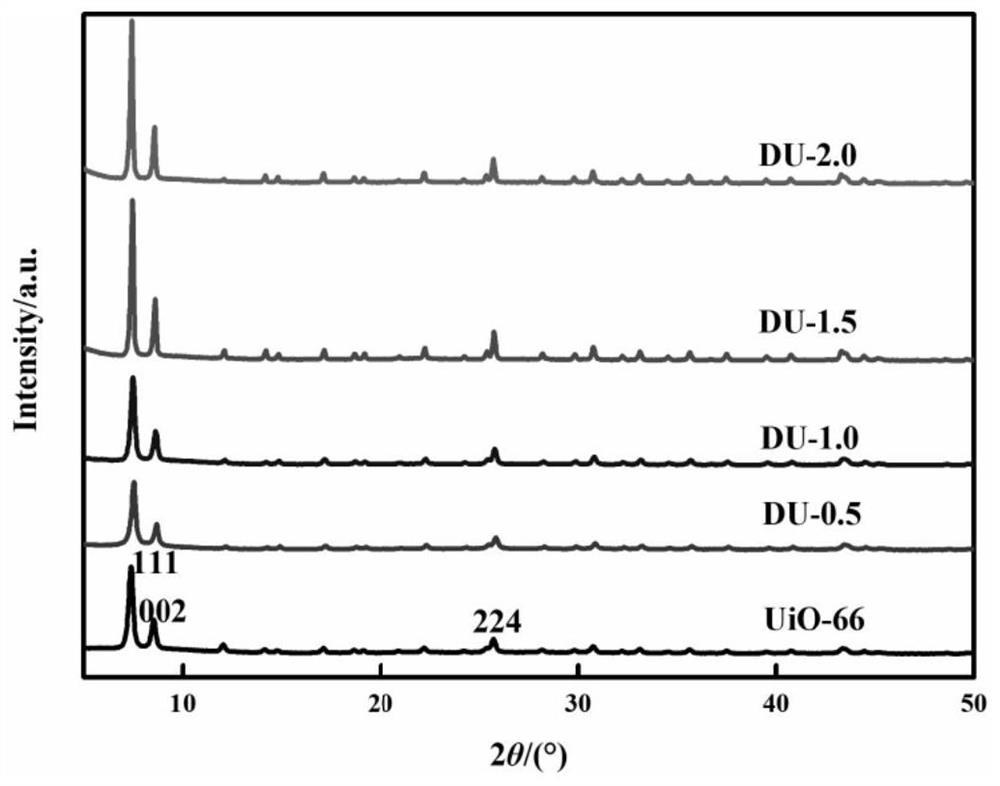

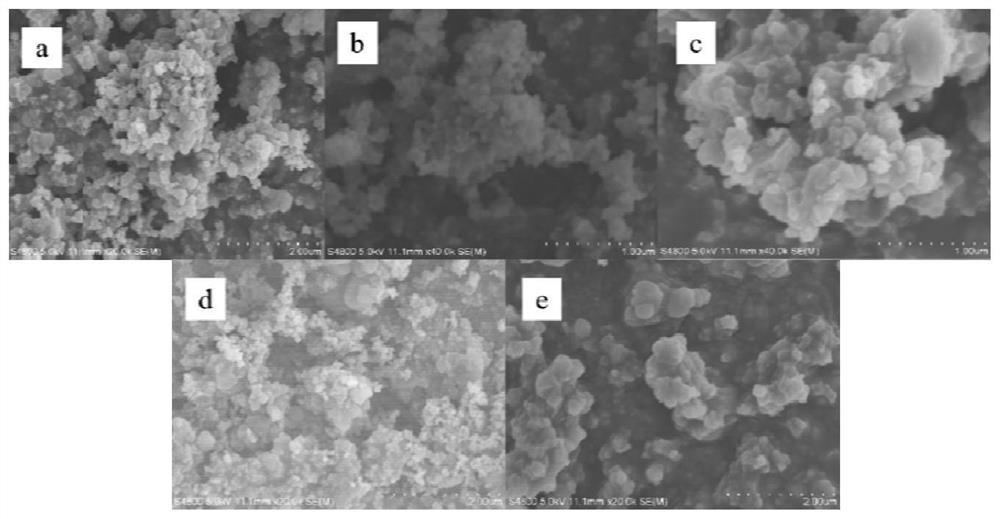

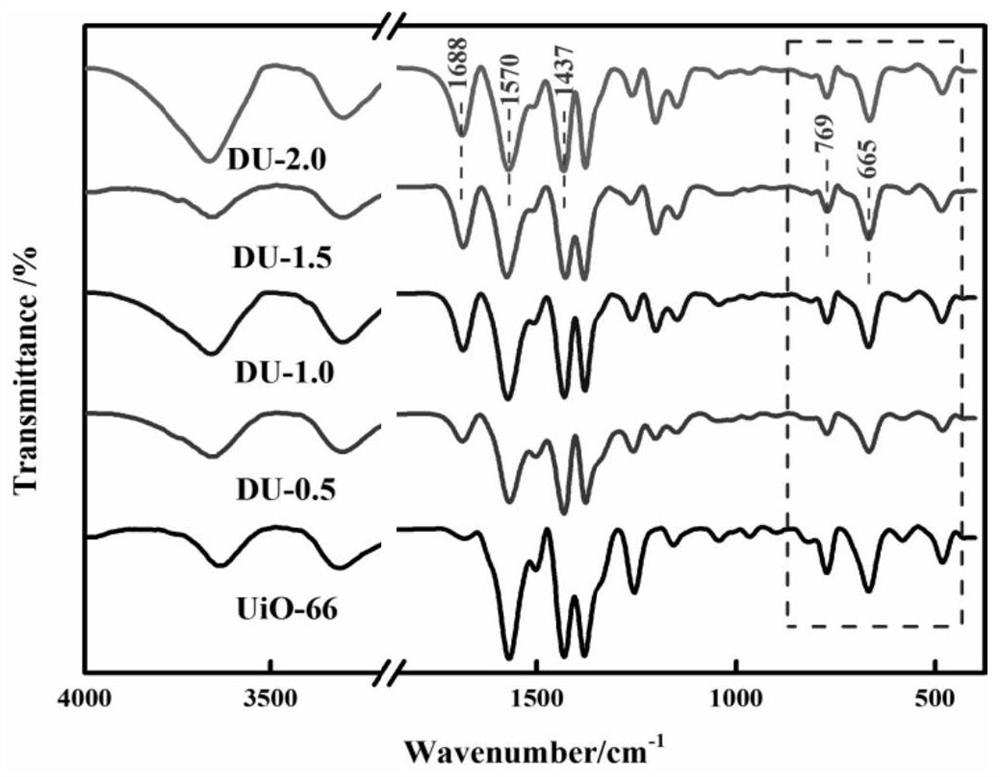

[0030] The invention discloses a method for preparing a defect-type UiO-66 photocatalytic material. When preparing a zirconium-based metal framed material UiO-66, adding a monocarboxylic acid crystal regulator to regulate the structure of UiO-66, a Defect-type UiO-66 photocatalytic material. The above method specifically includes the following steps:

[0031] The precursor solution is mixed with the monocarboxylic acid crystal modifier, stirred, subjected to solvothermal reaction, purified and then dried to obtain the defective UiO-66 photocatalytic material.

[0032] The precursor solution is a mixed solution of a metal zirconium salt and an organic ligand; specifically, the solvent used for the precursor solution is N,N-dimethylformamide, N,N-dimethylpropionamide, N,N - one or more of diethylpropionamide; specifically, the metal zirconium salt is one or more of zirconium tetrachloride, zirconium nitrate, zirconium oxychloride; specifically, the organic ligand is amino One ...

Embodiment 1

[0040] A preparation method of defect-type UiO-66 photocatalytic material, comprising the following steps:

[0041] Weigh 247.5mg (1.0mmol) of zirconium tetrachloride, ultrasonically dissolve it in 25mL N,N-dimethylformamide solution, record it as solution 1, and set aside; weigh 9.6mg (0.5mmol) of aminoterephthalic acid, ultrasonically Dissolve in 25mL N,N-dimethylformamide solution, record it as solution 2, and set aside; pour solution 2 into solution 1, keep stirring for 15 minutes, add 0.5mL trifluoroacetic acid to it, continue stirring to mix evenly , transfer the mixed solution to a 100mL autoclave at 120°C for 24 hours, turn off the oven after the reaction, cool to room temperature, centrifuge the mixed product to obtain a precipitate, and use N,N-dimethylformamide for the obtained precipitate Washing and washing with methanol three times respectively, centrifuging after washing to obtain a solid product; soaking the obtained solid product in methanol at room temperatur...

Embodiment 2

[0043] A preparation method of defect-type UiO-66 photocatalytic material, comprising the following steps:

[0044] Weigh 247.5mg (1.0mmol) of zirconium tetrachloride, ultrasonically dissolve it in 25mL N,N-dimethylformamide solution, record it as solution 1, and set aside; weigh 192.4mg (1.0mmol) of aminoterephthalic acid, Ultrasonic dissolved in 25mL N,N-dimethylformamide solution, recorded as solution 2, and set aside; Pour solution 2 into solution 1, after stirring continuously for 15min, add 1.0mL trifluoroacetic acid to it, continue stirring to mix Evenly, transfer the mixed solution to a 100mL autoclave at 180°C for 12 hours, turn off the oven after the reaction, cool to room temperature, centrifuge the mixed product to obtain a precipitate, and use N,N-dimethyl formaldehyde Amide washing and methanol washing 3 times respectively, after the washing, centrifuge to obtain a solid product; soak the obtained solid product in methanol at room temperature for 12 hours, centri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com