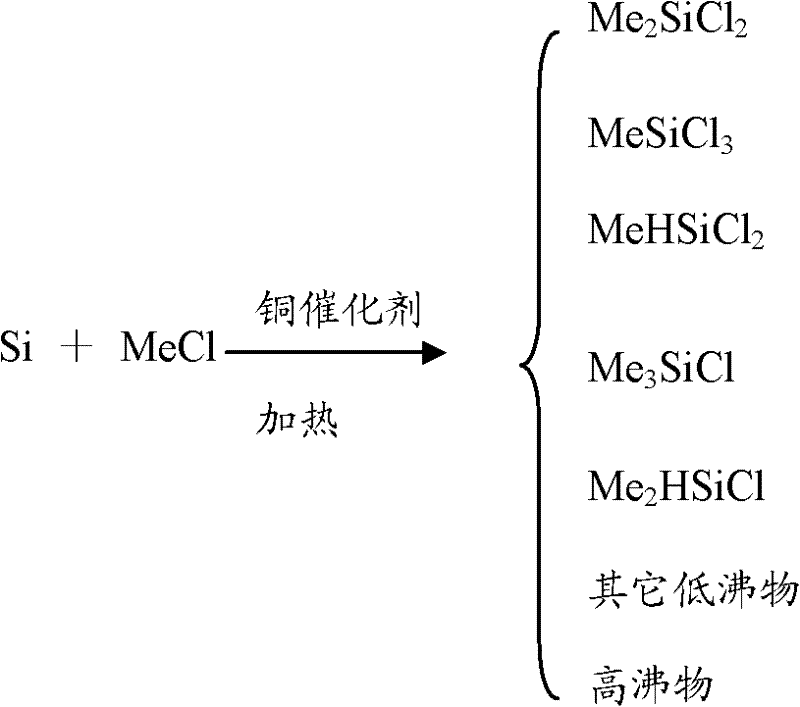

Reparation method of ternary copper CuO-Cu2O-Cu catalyst for synthesizing methyl chlorosilane

A technology of cuo-cu2o-cu and methyl chlorosilane, which is applied in chemical instruments and methods, organic chemistry, compounds of group 4/14 elements of the periodic table, etc., can solve the problem of poor selectivity, no indication, and complicated preparation process etc. to achieve the effects of easy operation and control, improved catalytic effect, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Primary oxidation ball-milled copper catalyst: Weigh 5g of electrolytic copper powder, put it in a corundum boat, put it into a tube furnace, replace the air in the heating furnace with nitrogen, and when it is heated to an oxidation temperature of 250°C, pass in air for one Oxidation, the molar ratio of the amount of air to be added to the copper powder is 10:1, after the air is introduced for 0.5h, stop the air and heat; perform a wet ball mill after the reaction, take the above-mentioned primary oxidation sample 5g, The mass ratio of ball milling beads to material is 20:1, the mass ratio of ball milling beads to dispersant water is 2:1, and the ball milling time is 4h; Ball milled copper catalyst. Gained copper catalyst is composed as follows after chemical analysis: 38% Cu (percentage by weight, the same below), 49% Cu 2 O and 13% CuO; the obtained copper catalyst was analyzed for particle size in Dandong Baite BT-9300Z laser particle size distribution instrumen...

Embodiment 2

[0035] 1. Primary oxidation ball-milled copper catalyst: Weigh 5g of electrolytic copper powder, put it in a corundum boat, put it into a tube furnace, replace the air in the heating furnace with nitrogen, and when it is heated to an oxidation temperature of 320°C, pass in air for one Oxidation, the molar ratio of the amount of air to be added to the copper powder is 1:1, and after the air is introduced for 2.5 hours, the air and heating are stopped; after the reaction is completed, a dry ball mill is carried out, and 5g of the above-mentioned primary oxidation sample is taken. The mass ratio of the ball milling beads to the material is 2:1, and the ball milling time is 0.5 h; after the ball milling, the milled sample is taken out to obtain a primary oxidation ball milled copper catalyst. Gained copper catalyst is composed as follows after chemical analysis: 28% Cu (percentage by weight, the same below), 54% Cu 2 O and 18% CuO; the obtained copper catalyst was analyzed for par...

Embodiment 3

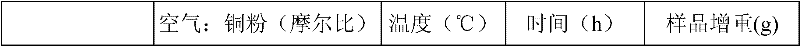

[0038] 1. Primary oxidation ball-milled copper catalyst: Weigh 5g of electrolytic copper powder, put it in a corundum boat, put it into a tube furnace, replace the air in the heating furnace with nitrogen, and when it is heated to an oxidation temperature of 400°C, pass in air for a Oxidation, the molar ratio of the amount of air to be added to the copper powder is 5:1, after the air is fed for 5 hours, stop the air and heat; after the reaction is completed, perform a wet ball mill, take 5g of the above-mentioned primary oxidation sample, and ball mill The mass ratio of beads to material is 10:1, the mass ratio of ball milling beads to dispersant water is 5:1, and the ball milling time is 8 hours; after ball milling, the sample after ball milling is vacuum filtered and dried to obtain a primary oxidation ball mill copper catalyst. Gained copper catalyst is composed as follows after chemical analysis: 20% Cu (percentage by weight, the same below), 57% Cu 2 O and 23% CuO; the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com