Method for producing cigarette expansion cut tobacco with low tar content and low harm by using microbial fermentation

A microbial fermentation and microbial technology, applied in the fields of tobacco, application, and tobacco treatment, to achieve the effect of good tar reduction and harm reduction, simple operation process and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

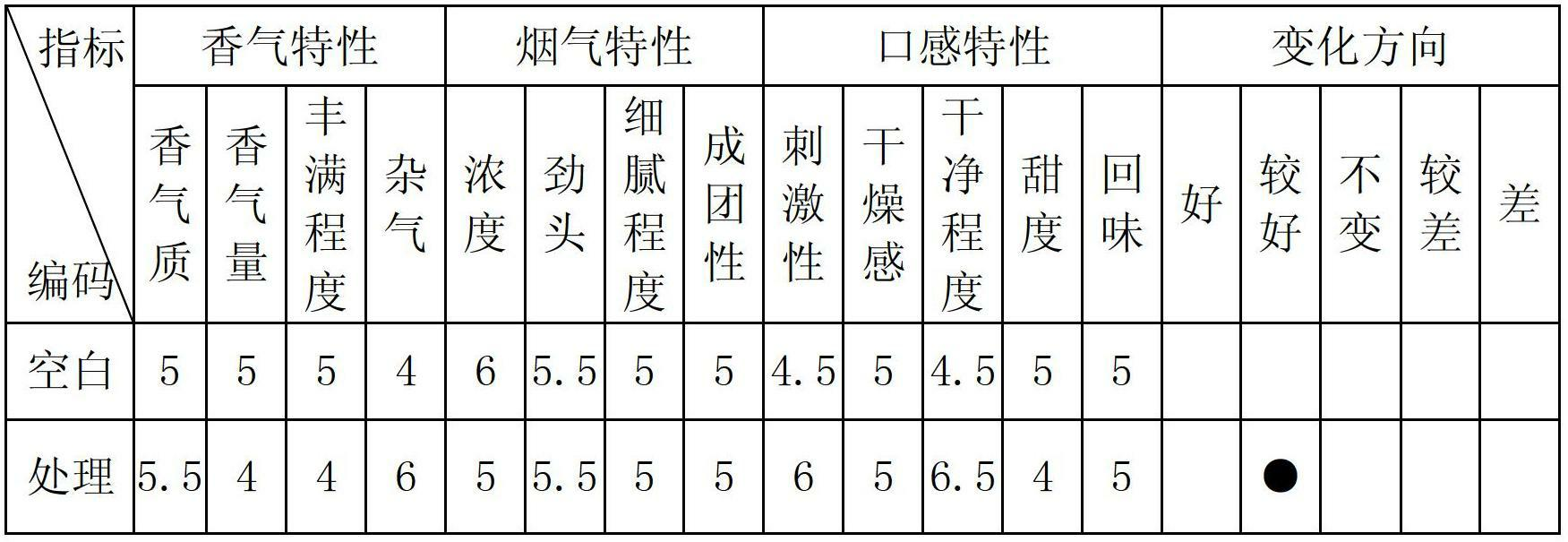

Image

Examples

Embodiment 1

[0018] Select low-grade tobacco leaves, Guangyuan, Sichuan, Yunyan 85, 2011, CX1K, and inoculate the mixed bacterial solution of the above-mentioned Hansenula anomaly and Bacillus megaterium in the re-moisture feeding link, and the concentration of the two bacteria solutions reaches 10 9 CFU / mL, the spraying ratio is 10% (accounting for the mass percentage of the tobacco leaf weight), after shredded, it is stacked and fermented in the storage cabinet for 48 hours, the temperature is 28-37 °C, the humidity is 60%-85%, and then the CO 2 Expanded to obtain expanded shredded leaf Y1, rolled into 84mm (24+60) cigarettes, the conventional chemical composition and tar and CO release of the treated sample and the blank were analyzed, see Table 1 and Table 2.

[0019] Table 1 Comparison of conventional chemical components between CX1K treated sample and blank sample

[0020]

blank sample

Processing sample

reduce

Reducing sugar (%)

...

Embodiment 2

[0028] Select low-grade tobacco leaves, Xichang, Sichuan, red big tobacco leaves, 2010, B1K, spray the mixed bacterial solution of the above-mentioned Hansenula anomaly and Bacillus pumilus after the tobacco leaves are re-cured, and the concentration of the two bacterial solutions reached 10 10 CFU / mL, the spraying ratio is 5% (mass percentage of tobacco leaf weight), naturally aged in the warehouse for one year, after CO 2 After the process of expanded shredded leaf by the method, the expanded shredded leaf Y2 was obtained, and after being rolled into cigarettes with a specification of 84mm (24+60), the conventional chemical composition, tar and CO release of the treated sample and the blank were analyzed, as shown in Table 4 and Table 5.

[0029] Table 4 Comparison of conventional chemical components between B1K treated sample and blank sample

[0030]

blank sample

Processing sample

reduce

reduce%

Reducing sugar (%)

13.03

6.48 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com