Mammal embryo and oocyte vitrification freezing carrier

A vitrification and oocyte technology, applied in the field of vitrification of mammalian embryos and oocytes, can solve the problems of unfavorable long-term storage of samples, increase the difficulty of operation, and significant siphon effect, so as to reduce freezing damage, It is convenient for long-term storage and has a remarkable cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

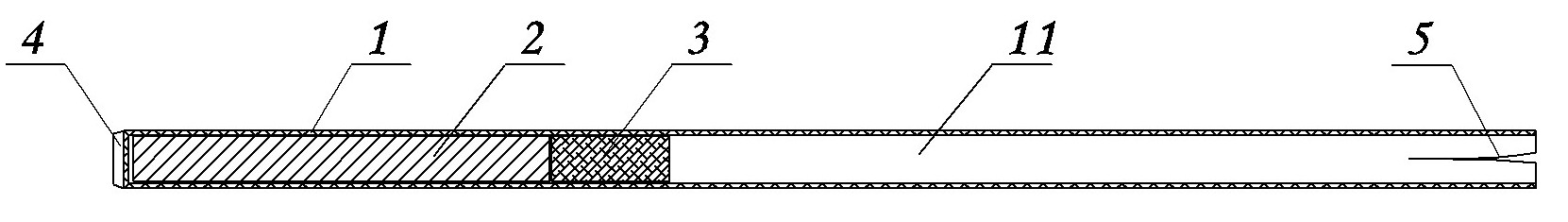

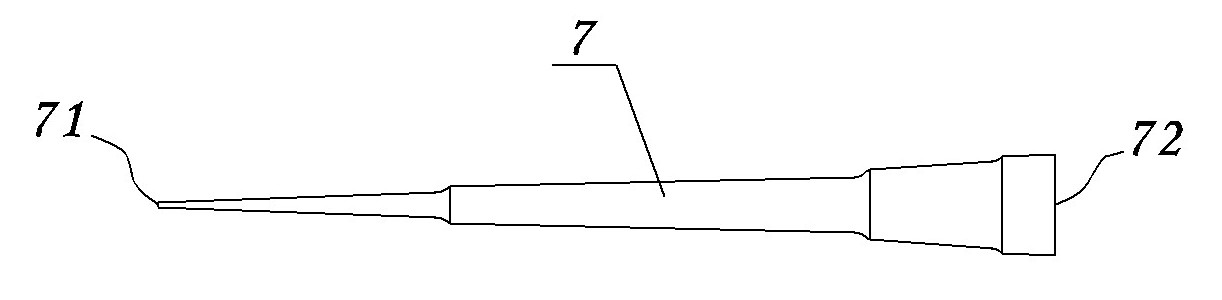

[0021] Example 1: see figure 1 with figure 2 The vitrification carrier for mammalian embryos and oocytes includes a freezing thin tube 1 and a conical tip 7, which are matched and installed in a buckle.

[0022] figure 1 Wherein, the front end of the frozen thin tube 1 and the conical suction head 7 are provided with at least one longitudinal shearing opening 5, which is convenient for matching and fitting with the conical suction head and has tightness. figure 2 Wherein, the tip of the tapered tip 7 is provided with an incision 71, the other end is an installation opening 72, and the aperture at the incision 71 ranges from 100 μm to 200 μm. Install the conical tip 7 with an Eppendorf 20 μl pipette, put the carrier device into liquid nitrogen together, and insert the conical tip 7 holding the frozen sample into the cryotube 1 from the cut opening 5 with tweezers. After all the samples are frozen, put all the frozen straws 1 into the grapes in the liquid nitrogen tank, and put th...

Embodiment 2

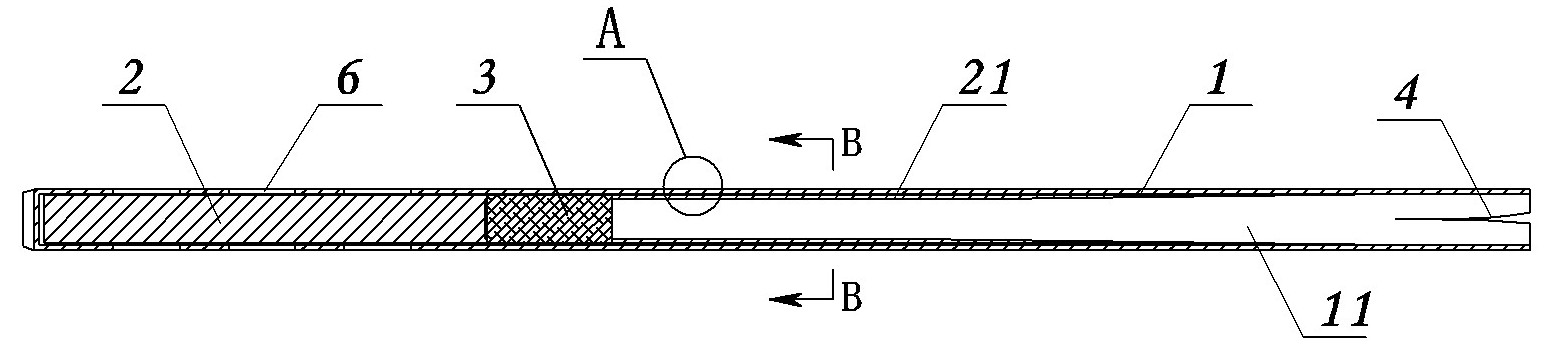

[0024] Example 2: see image 3 , Figure 4 with Figure 5 The content is basically the same as the first embodiment, and the similarities are not repeated. The difference is that a hole 6 is provided on the side wall of the frozen thin tube contacted by the metal weight body 2. In addition, the front end of the metal weight body 2 is provided with a fork-shaped rib 21, the fork-shaped rib 21 passes through the partition and extends into the storage cavity 11, and is attached and fixed on the inner side wall of the freezing thin tube 1. The fork-shaped rib 21 not only has a strengthening and supporting effect on supporting the frozen thin tube, but also has the effect of accelerating cooling when connected with the metal weight body, and the cooling effect is remarkable.

Embodiment 3

[0025] Example three: see Image 6 The content is basically the same as the second embodiment, and the similarities will not be repeated. The difference is: the metal weight body 2 is exposed outside the frozen thin tube, and the metal weight body 2 is only partially fixed with the frozen thin tube 1. The front end of the weight body 2 is provided with a fork-shaped rib 21, the fork-shaped rib 21 passes through the partition 3 and then extends into the storage cavity 11, and is attached and fixed on the inner side wall of the freezing thin tube 1. The leaking metal weight body 2 is more conducive to heat conduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com