Circuit for realizing passivity of intelligent photo wiring interface plate in port enabling way

An optical wiring and wiring technology, applied in the field of optical communication, can solve the problems of pollution and static electricity hazards, limit the operating space of the fiber fusion construction site, reduce the installation density of equipment, etc. Anti-static and anti-fouling ability, the effect of strong anti-static and anti-fouling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

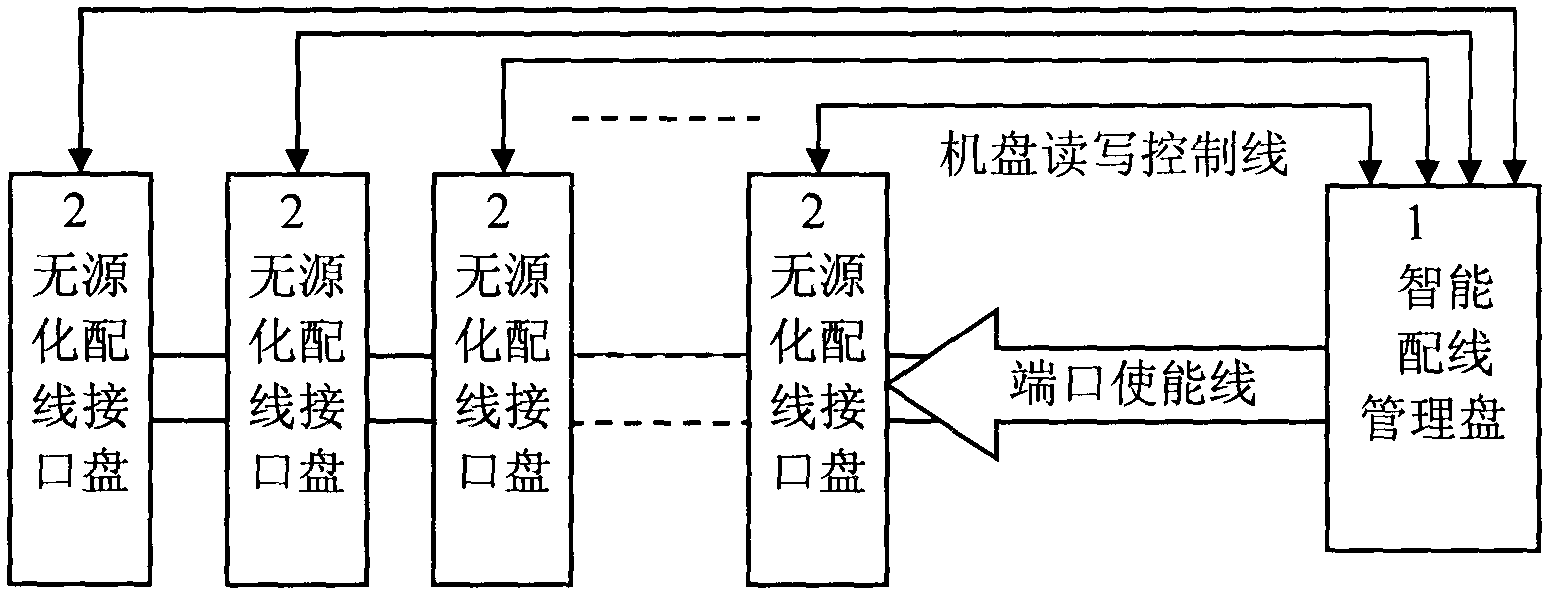

[0061] Embodiment 1: Combining machine disk read and write control + grouping port enablement.

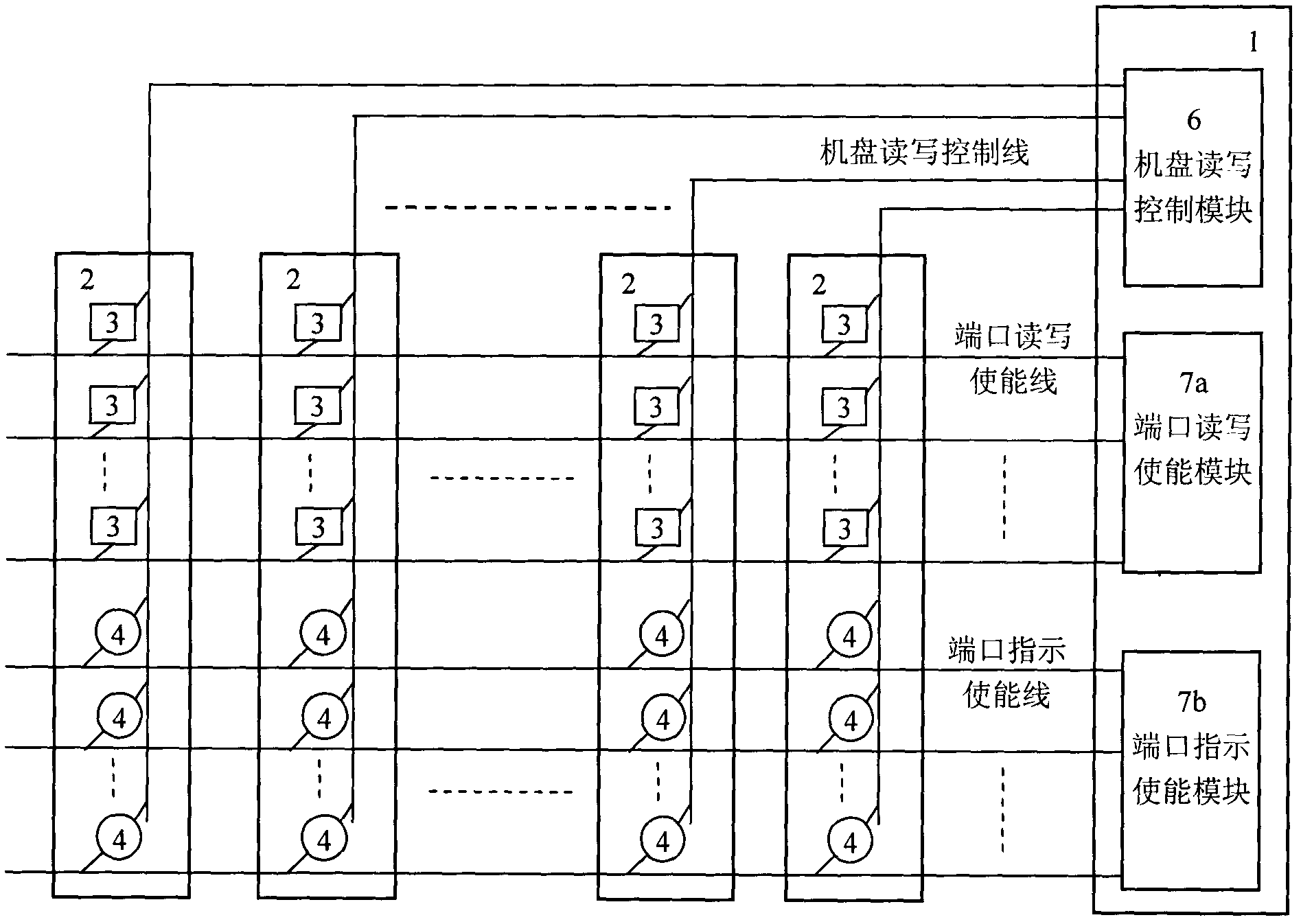

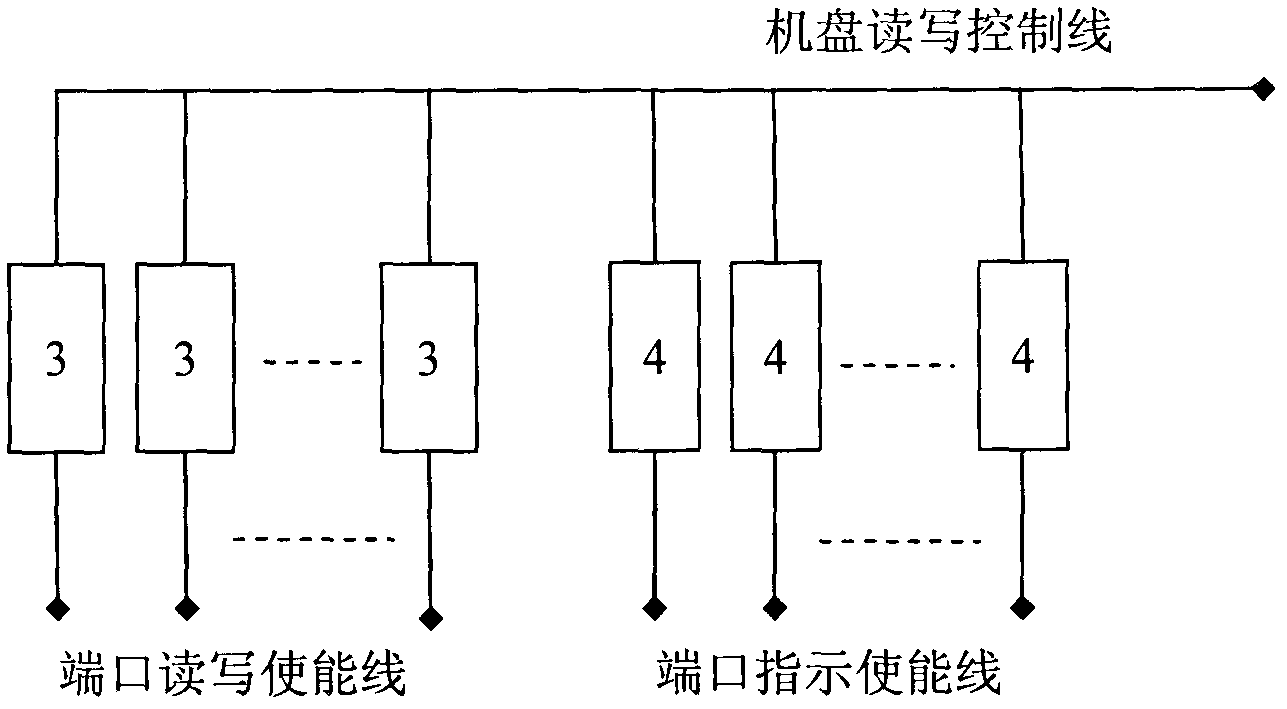

[0062] see figure 2 As shown, the intelligent wiring management disk 1 includes a machine disk read-write control module 6, a port read-write enable module 7a and a port indication enable module 7b, see image 3 As shown, the signal read-write end of each wiring information read-write interface 3 in each passive wiring interface panel 2 and the display control end of each wiring port indicator 4 are connected together and drawn out as the passive The machine disk read and write control terminal of wiring interface disk 2. see figure 2 As shown, the disk read-write control module 6 leads out several disk read-write control lines, which are respectively connected to the disk read-write control terminals of the passive wiring interface disks 2 .

[0063] see image 3 As shown, the reference control terminals of each wiring information read-write interface 3 in each passive wirin...

Embodiment 2

[0064] Embodiment 2: group machine disk read and write control + group port enable.

[0065] In order to further increase the port management capacity of the bus, or manage ports for classification, each port device that needs to be managed can be managed in groups.

[0066] see Figure 4 As shown, the intelligent wiring management disk 1 includes a machine disk information read-write module 6a, a machine disk indication control module 6b, a port read-write enable module 7a and a port indication enable module 7b, see Figure 5 As shown, the signal read-write terminals of each wiring information read-write interface 3 in each passive wiring interface panel 2 are connected together as the disk information read-write terminal of the passive wiring interface panel 2, with Accept the read and write control of the machine disk port of the intelligent wiring management panel 1; The panel port indication control of the wiring management panel.

[0067] The disk read-write control l...

Embodiment 3

[0069] Embodiment 3: Group machine disk read and write control + combined port enablement.

[0070] see Image 6 As shown, the intelligent wiring management panel 1 includes a machine disk information reading and writing module 6a, a machine disk indication control module 6b and a port enabling module 7, see Figure 7 As shown, the signal read-write terminals of each wiring information read-write interface 3 in each passive wiring interface panel 2 are connected together as the disk information read-write terminal of the passive wiring interface panel 2, each The display control terminals of the wiring port indicator 4 are connected together as the machine panel indicating control terminal of the passive wiring interface panel 2 . The disk read-write control line in this embodiment is divided into the disk information read-write line and the disk indication control line, see Image 6 As shown, the machine disk information reading and writing module 6a leads to several machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com