Method for preparing elastomer based on Click reaction

An elastomer and reaction technology, applied in the field of new materials, can solve the problems of long-time heating and slow speed, and achieve the effects of good mechanical properties, simple preparation process and great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

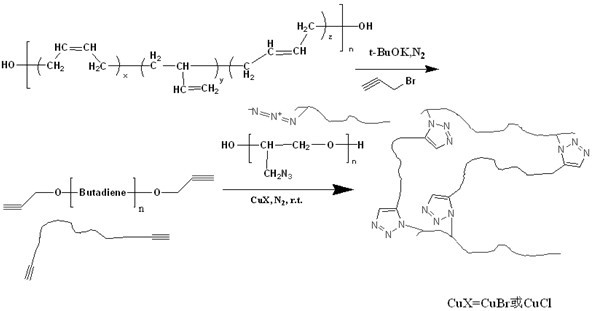

Method used

Image

Examples

Embodiment 1

[0037] A kind of preparation method based on the elastomer of Click reaction, it comprises the steps:

[0038] 1) Preparation of alkynylated polybutadiene: Hydroxyl-terminated polybutadiene (HTPB, i.e., butylated hydroxyl) was vacuum-dried at 50 oC for 2 h; the hydroxyl-terminated polybutadiene with a hydroxyl value of 0.8399 mmol KOH / g was weighed Dissolve 10.52g of alkenes in 20mL of THF to obtain a THF solution containing HTPB; another 2.16g of potassium tert-butoxide (t-BuOK) was dissolved in 20mL of THF to obtain a t-BuOK solution; Slowly add the THF solution containing HTPB into the t-BuOK solution, and continue to stir for 10 minutes to obtain the reaction solution A; take 2.4mL of propargyl bromide (80% w / w, ca. 9.2mol / L) and dissolve it in 60mL of THF [The total amount of —OH in hydroxyl-terminated polybutadiene (HTPB, ie, butylated hydroxyl group): Potassium tert-butoxide (t-BuOK): the molar ratio of propyne bromide=1:2.2:2.5], in N 2 Under the conditions of protect...

Embodiment 2

[0045] A kind of preparation method based on the elastomer of Click reaction, it comprises the steps:

[0046] 1) Preparation of alkynylated polybutadiene: Hydroxyl-terminated polybutadiene (HTPB, i.e., butylated hydroxyl) was vacuum-dried at 50 oC for 2 h; the hydroxyl-terminated polybutadiene with a hydroxyl value of 0.8399 mmol KOH / g was weighed 10.98g of alkenes was dissolved in 20mL of THF to obtain a THF solution containing HTPB; another 2.08g of potassium tert-butoxide (t-BuOK) was dissolved in 20mL of THF to obtain a t-BuOK solution; Slowly add the THF solution containing HTPB into the t-BuOK solution, and continue to stir for 10 min to obtain the reaction solution A; take 2.0 mL of propargyl bromide (80% w / w, ca. 9.2 mol / L) and dissolve it in 100 mL of THF [The total amount of —OH in hydroxyl-terminated polybutadiene (HTPB, ie, butylated hydroxyl group): Potassium tert-butoxide (t-BuOK): the molar ratio of propyne bromide=1:2.0:2.0], in N 2 Under the conditions of pr...

Embodiment 3

[0053] A kind of preparation method based on the elastomer of Click reaction, it comprises the steps:

[0054] 1) Preparation of alkynylated polybutadiene: Hydroxyl-terminated polybutadiene (HTPB, i.e., butylated hydroxyl) was vacuum-dried at 50 oC for 2 h; the hydroxyl-terminated polybutadiene with a hydroxyl value of 0.8399 mmol KOH / g was weighed 10.96g of alkenes was dissolved in 20mL of THF to obtain a THF solution containing HTPB; another 2.08g of potassium tert-butoxide (t-BuOK) was dissolved in 20mL of THF to obtain a t-BuOK solution; Slowly add the THF solution containing HTPB into the t-BuOK solution, and continue to stir for 10 min to obtain the reaction solution A; take 2.0 mL of propargyl bromide (80% w / w, ca. 9.2 mol / L) and dissolve it in 100 mL of THF [The total amount of —OH in hydroxyl-terminated polybutadiene (HTPB, ie, butylated hydroxyl group): Potassium tert-butoxide (t-BuOK): the molar ratio of propyne bromide=1:2.0:2.0], in N 2 Under the conditions of pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com