High near-infrared reflectivity nano-ceramic pigment and preparation method thereof

A nano-ceramic, infrared reflection technology, applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., to achieve the effect of small concentration, increase reflectivity, and reduce absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

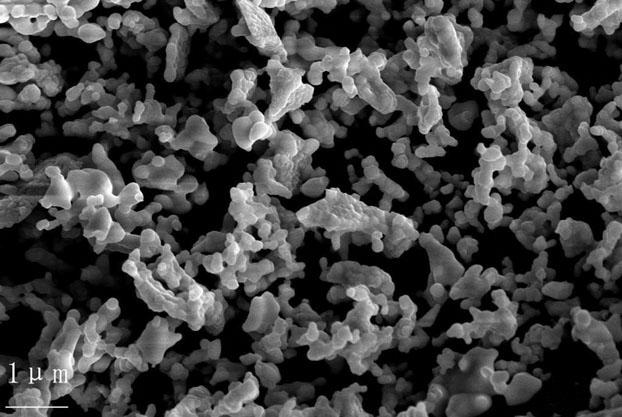

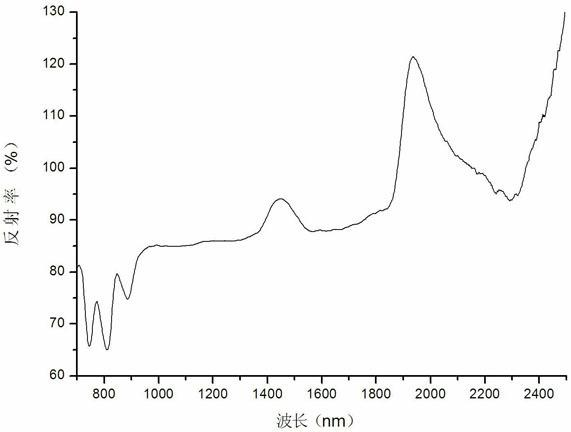

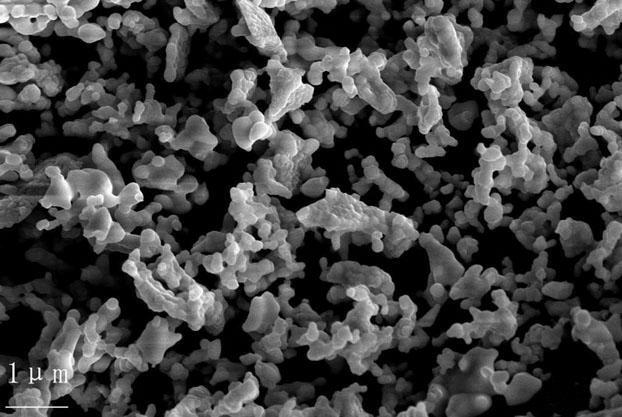

Image

Examples

Embodiment 1

[0041] The raw material components of the high near-infrared reflection nano-ceramic pigment are as follows: 55 parts of yttrium oxide, 30 parts of neodymium oxide, and 15 parts of molybdenum oxide.

[0042] The preparation method steps are as follows:

[0043]1. According to the proportion, the powders of yttrium oxide, neodymium oxide and molybdenum oxide were mixed by ball milling for 30 minutes with absolute ethanol as solvent; the slurry mixed by ball milling was dried under vacuum condition at 60°C to obtain mixed powder.

[0044] 2. The above-mentioned mixed powder is calcined in a heating furnace under an air atmosphere without pressure, and when the temperature is raised to the highest calcining temperature of 1600°C, it is kept for 60 minutes; naturally cooled. Routine selections can be made by those skilled in the art.

[0045] 3. Crushing and sieving the calcined product obtained after the above calcining to obtain pigment powder.

[0046] The properties of the o...

Embodiment 2

[0048] The raw material components of the high near-infrared reflection nano-ceramic pigment are as follows: 60 parts of yttrium oxide, 25 parts of neodymium oxide, and 15 parts of molybdenum oxide.

[0049] The preparation method steps are as follows:

[0050] 1. According to the proportion, the powders of yttrium oxide, neodymium oxide and molybdenum oxide were mixed by ball milling for 35 minutes with absolute ethanol as solvent; the slurry mixed by ball milling was dried under vacuum condition at 70°C to obtain mixed powder.

[0051] 2. The above-mentioned mixed powder is calcined in a heating furnace under an air atmosphere without pressure, and when the temperature is raised to the highest calcining temperature of 1400°C, it is kept for 150 minutes; naturally cooled. Routine selections can be made by those skilled in the art.

[0052] 3. Crushing and sieving the calcined product obtained after the above calcining to obtain pigment powder.

[0053] The properties of the...

Embodiment 3

[0055] The raw material components of the high near-infrared reflection nano-ceramic pigment are as follows: 65 parts of yttrium oxide, 20 parts of neodymium oxide, and 15 parts of molybdenum oxide.

[0056] The preparation method steps are as follows:

[0057] 1. According to the proportion, the powders of yttrium oxide, neodymium oxide and molybdenum oxide were mixed by ball milling for 40 minutes with absolute ethanol as solvent; the slurry mixed by ball milling was dried under vacuum condition at 70°C to obtain mixed powder.

[0058] 2. The above-mentioned mixed powder is calcined in a heating furnace under an air atmosphere without pressure, and when the temperature is raised to the highest calcining temperature of 1500 ° C, it is kept for 180 min; naturally cooled. Routine selections can be made by those skilled in the art.

[0059] 3. Crushing and sieving the calcined product obtained after the above calcining to obtain pigment powder.

[0060] The properties of the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com