Method for preparing spherical porous alumina carrier

A technology of porous alumina and aluminum hydroxide, applied in the direction of catalyst carrier, chemical instrument and method, alumina/aluminum hydroxide, etc. Equilibrium problem, to achieve the effect of strengthened bonding, good pore structure and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

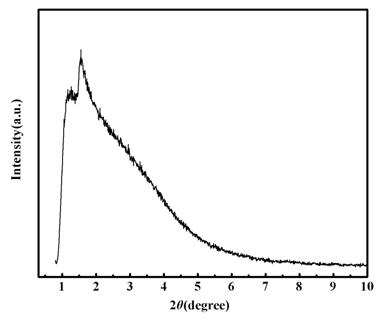

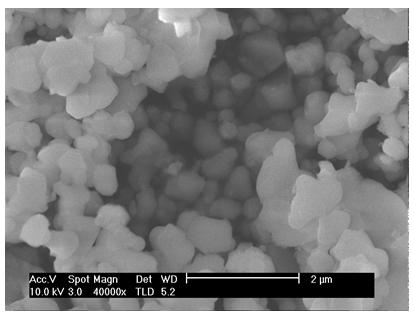

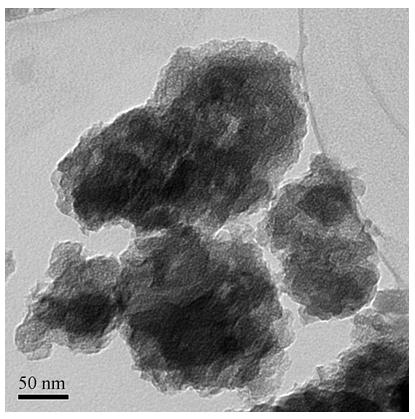

[0026] A method for preparing a spherical porous alumina carrier, the steps of the preparation process comprising:

[0027] (1) Dissolve aluminum hydroxide with hydrochloric acid or sulfuric acid solution to make an acidic aqueous solution of aluminum ions;

[0028] (2) Introduce the prepared acid solution into NaOH solution drop by drop under the hydrothermal system, stir vigorously, control the final pH value of the system to be stable between 3.0 and 5.0, and then perform aging treatment at room temperature;

[0029] (3) Vigorously stir the aged solution under the hydrothermal system, quickly add the templating agent solution, and then introduce the reaction aid; continue to fully stir the above mixed system under the hydrothermal condition;

[0030] (4) After fully washing and filtering with deionized water, spray-dry to obtain the precursor powder;

[0031] (5) The precursor powder is roasted to obtain spherical porous activated alumina.

Embodiment 1

[0033] First, fully dissolve 1g of sodium laurate in 20ml of deionized water to prepare solution C, then measure 50ml of solution B, and quickly add solution C under 80°C hydrothermal system. After stirring vigorously for 1 hour, 0.2 g of citric acid was introduced as a reaction aid. Continue to fully stir the above mixed system for 12 hours under hydrothermal conditions, then use deionized water to fully filter and use spray drying equipment to quickly obtain the precursor powder material, and finally roast the precursor powder at 700°C for 4 hours in an air atmosphere , the rate was controlled at 2°C / min during the heating period, and the spherical porous alumina carrier material was obtained by natural cooling

Embodiment 2

[0035] First fully dissolve 1.5g P123 in 20ml deionized water to prepare solution C, then measure 100ml of solution B, quickly add solution C under 60°C hydrothermal system, stir vigorously for 2 hours and introduce 0.5g lauric acid as a reaction aid . Continue to fully stir the above mixed system for 24 hours under hydrothermal conditions, and then use spray drying equipment to quickly obtain the precursor powder material after being fully filtered with deionized water, and finally roast the precursor powder at 700°C for 4 hours in an air atmosphere , and finally obtain a spherical porous activated alumina carrier, and the rate is controlled at 2°C / min during the heating period.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com