Antibacterial peptide composition and preparation method thereof

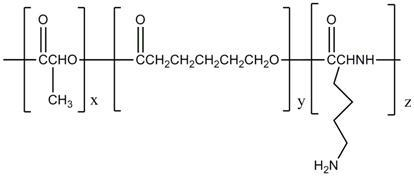

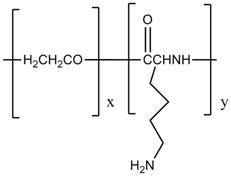

An antimicrobial peptide and composition technology, applied in the field of bioengineering, can solve the problems of lack of hydrophilicity, unfavorable antimicrobial peptide structure, etc., and achieve the effects of good biocompatibility and hydrophilic performance, good therapeutic effect, and a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 1 part of antimicrobial peptide Pexiganan and dissolve it in 19 parts of ultrapure water to make an inner aqueous phase with an antimicrobial peptide content of 5%. At the same time, 10 parts of polylactic acid-polyethylene glycol copolymer were weighed and dissolved in 190 parts of dichloromethane to prepare a medium oil phase. In the case of mechanical stirring at 500rpm, the inner water phase was added to the middle oil phase and stirred for half an hour to form colostrum. Weigh 6 parts of polyvinyl alcohol and add to 214 parts of ultrapure water to make the outer water phase. Add the colostrum into the external water phase, and stir for 1 hour under the action of stirring at a rotation speed of 700 rpm to form a W / O / W double emulsion. Add 40 parts of isopropanol to the double emulsion, stir in the open for 3 hours, centrifuge at a speed of 10000 rpm, and freeze-dry the precipitate to obtain the antimicrobial peptide composition.

Embodiment 2

[0040] Weigh 1 part of antimicrobial peptide Hlf1-11 and dissolve it in 99 parts of ultrapure water to make an inner aqueous phase with an antimicrobial peptide content of 1%. At the same time, 10 parts of polylactic acid-polytrimethylene carbonate-polylysine copolymer were weighed and dissolved in 190 parts of dichloromethane to prepare a medium oil phase. In the case of mechanical stirring at 500 rpm, 10 parts of the inner water phase were added to 90 parts of the middle oil phase, and stirred for half an hour to form colostrum. Weigh 3 parts of polyvinyl alcohol and add to 97 parts of ultrapure water to make the outer water phase. Add 10 parts of colostrum into 80 parts of the external water phase, and stir for 1 hour under stirring at a rotation speed of 700 rpm to form W / O / W double emulsion. Add 20 parts of isopropanol to 100 parts of double emulsion, stir in the open for 3 hours, centrifuge at 12000 rpm, and freeze-dry the precipitate to obtain the antimicrobial pep...

Embodiment 3

[0042] Weigh 1 part of antimicrobial peptide Plectasin and dissolve it in 99 parts of ultrapure water to make an inner aqueous phase with an antimicrobial peptide content of 1%. At the same time, 1 part of polylactic acid-polyglycolic acid-polyethylene glycol copolymer was weighed and dissolved in 99 parts of dichloromethane to prepare a medium oil phase. In the case of mechanical stirring at 500 rpm, 10 parts of the inner water phase were added to 40 parts of the middle oil phase, and stirred for half an hour to form colostrum. Weigh 3 parts of polyvinyl alcohol and add to 97 parts of ultrapure water to make the outer water phase. Add 10 parts of colostrum into 80 parts of the external water phase, and stir for 1 hour under stirring at a rotation speed of 700 rpm to form W / O / W double emulsion. Add 30 parts of isopropanol to 100 parts of double emulsion, stir in the open for 3 hours, centrifuge at 9000 rpm, and freeze-dry the precipitate to obtain the antimicrobial peptide co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com