Conduction cavity type electroluminescent material and preparation method and application thereof

An electroluminescent material and hole-type technology, applied in the direction of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve the problem of film formation, thermal stability, low solubility, and poor carrier transport performance , high blue light energy, etc., to achieve unique optical and optoelectronic properties, enhanced fluorescence emission intensity, and large atomic radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

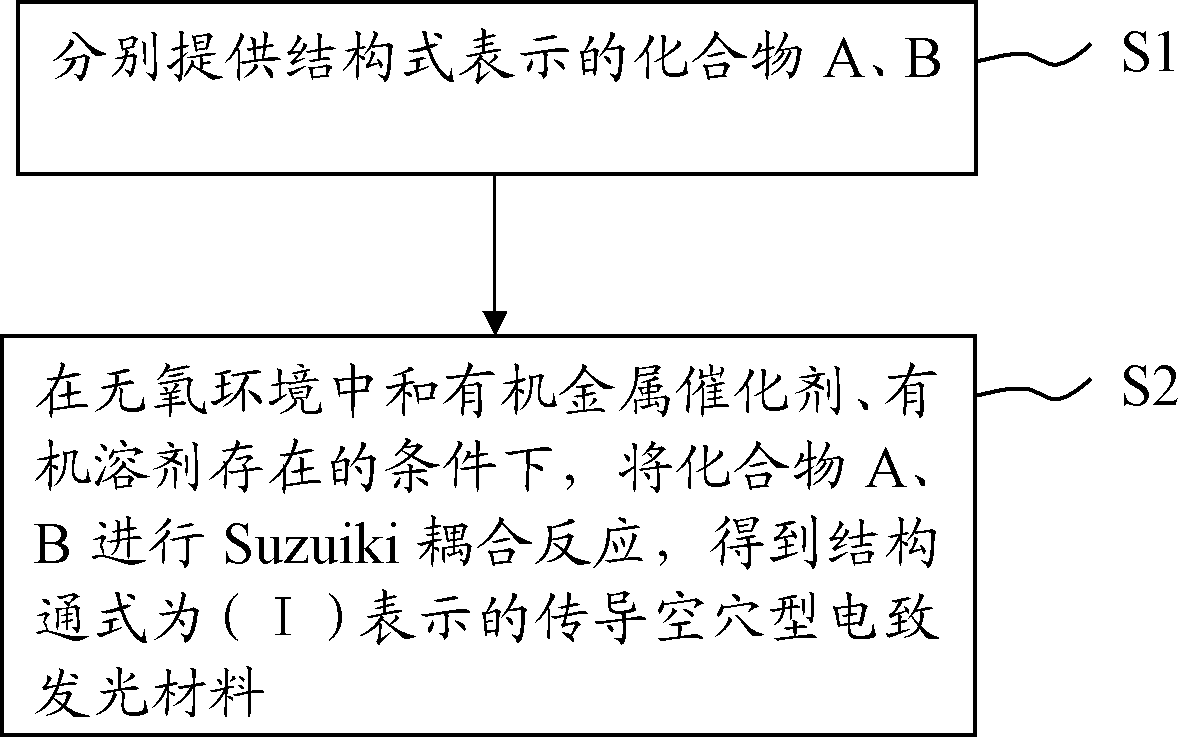

[0037] The embodiment of the present invention also provides the preparation method of the above-mentioned conductive hole-type electroluminescent material, please refer to figure 2 , the preparation method of the conduction hole type electroluminescent material comprises the following steps:

[0038] S1: Provide compounds A and B represented by the following structural formula respectively,

[0039]

[0040] Among them, X is Br or I; D is an electron-donating group; R is C1 ~C 12 straight-chain or branched-chain alkyl groups;

[0041] S2: In an oxygen-free environment and in the presence of an organometallic catalyst system and an organic solvent, the compounds A and B are subjected to a Suzuki coupling reaction to obtain a conductive hole-type electroluminescent material represented by the following structural general formula (I), The Suzuki coupling reaction formula of this step S2 can be expressed as follows:

[0042]

[0043] Specifically, in the step S1 of the ...

Embodiment 1

[0077] The conductive hole-type electroluminescent material 2,7,12-tris(5-(10-n-hexylanthracene-9-yl)selenophen-2-yl)-5,5',10,10' , the preparation of 15,15'-hexaethyltripolyindene (HSTET), its structural formula is as follows I 1 Shown:

[0078]

[0079] Its preparation steps are as follows:

[0080] 1) The preparation of compound 2,7,12-tribromo-5,5′,10,10′,15,15′-hexaethyltripolyindene, the specific preparation steps are as follows:

[0081] 1.1) The preparation of compound tripolyindene, its chemical reaction formula is as follows:

[0082]

[0083] The specific preparation process is as follows: 10 mmol of 1-indanone is added to a mixed solution containing 8 mL of acetic acid and 4 mL of concentrated hydrochloric acid, heated to 100° C., stirred and refluxed for 20 h. After the reaction, the reaction solution was poured into a beaker filled with ice water, and a large amount of solid precipitated immediately. After the precipitate was washed with water, acetone ...

Embodiment 2

[0108] The conductive hole-type electroluminescent material 2,7,12-tris(5-(10-n-hexyloxyanthracene-9-yl)selenophen-2-yl)-5,5′,10,10 Preparation of ',15,15'-hexaethyltripolyindene (HOSTET), whose structural formula is as follows I 2 Shown:

[0109]

[0110] Its preparation steps are as follows:

[0111] 1) Preparation of compound 2,7,12-tribromo-5,5′,10,10′,15,15′-hexaethyltripolyindene: please refer to step (1) in Example 1 for its preparation method .

[0112] 2) Preparation of compound 2-(4,4,5,5-tetramethyl-1,3,2-dioxaborolane)-5-(10-n-hexyloxyanthracene-9-yl)selenophene , and its chemical reaction formula is as follows:

[0113]

[0114]2.1) Preparation of compound 10-n-hexyloxy-9-bromoanthracene: Dissolve 15mmol of 10-n-hexyloxyanthracene in 25mL of dichloromethane, and dissolve 16mmol of NBS in 15mL of dichloromethane. Slowly drop the dichloromethane solution of 10-n-hexyloxyanthracene into the reaction flask, drop into 1ml of glacial acetic acid, and react in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com