Zinc-doped indium oxide nano gas sensitive material and preparation method thereof

A gas-sensitive material, zinc-doped technology, applied in chemical instruments and methods, luminescent materials, inorganic chemistry, etc., can solve the problem of high cost, and achieve the effects of fast response recovery, high sensitivity, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

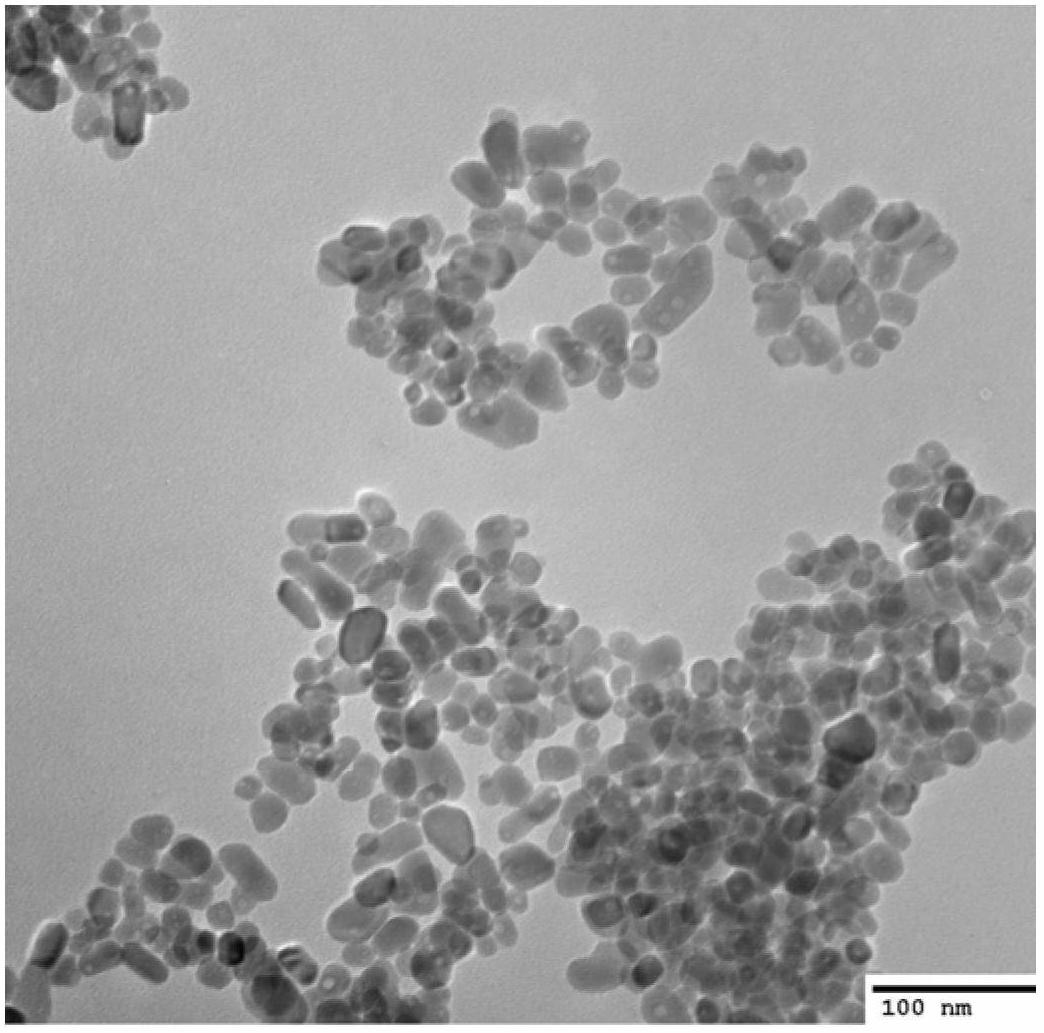

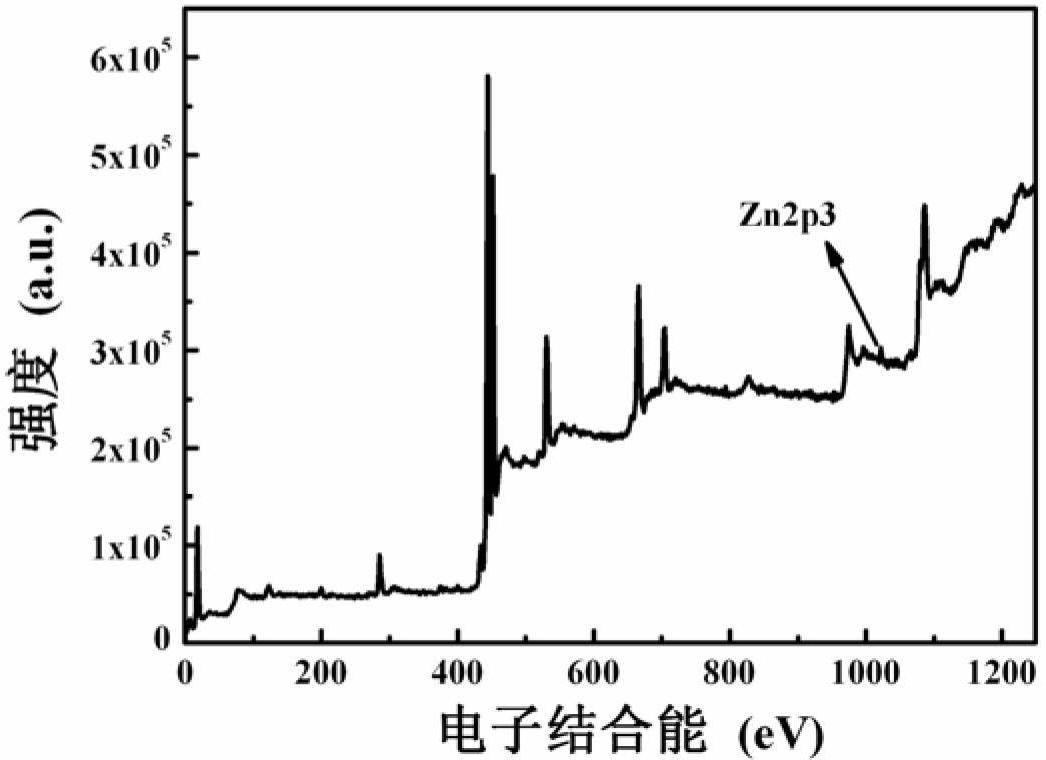

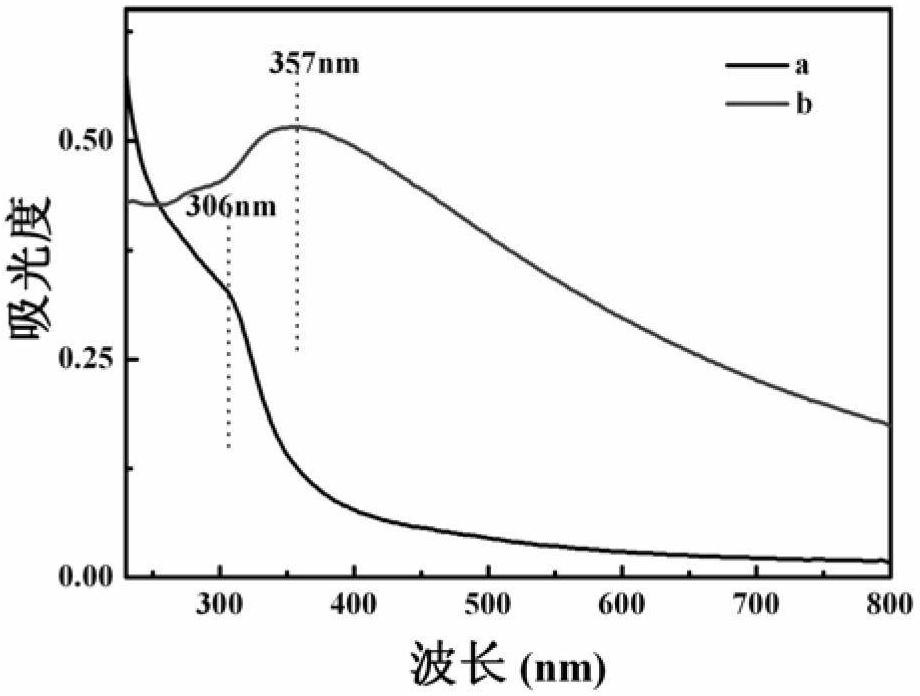

Embodiment 1

[0036] A. Dissolve indium chloride, zinc nitrate and hexamethylenetetramine in deionized water to prepare a solution with a concentration of 0.075mol / L, and then mix the three solutions at a volume ratio of 1:1:1. Sonicate for 15 minutes to prepare a reaction solution.

[0037]B. Put the reaction solution in A in a water bath and react at 70°C for 12 hours to obtain a precipitate; purify the precipitate at 20°C for 144 hours and then centrifuge it. The speed of the centrifuge is 4000r / min. The precipitate was washed with deionized water and ethanol.

[0038] C. The separated precipitate of B was dried in an oven at 60°C for 24 hours, and then calcined at 500°C for 3 hours to obtain zinc-doped indium oxide nanomaterials.

[0039] The obtained zinc-doped indium oxide was uniformly coated on the surface of the ceramic tube, and then aged at 300° C. for 48 hours. Solder the ceramic tube on the circuit board to conduct the gas sensitivity test directly, the results are shown in ...

Embodiment 2

[0041] A. Dissolve indium chloride, zinc nitrate and hexamethylenetetramine in deionized water to prepare a solution with a concentration of 0.050mol / L, and then mix these three solutions at a volume ratio of 1:0.0376:1, Sonicate for 15 minutes to prepare a reaction solution.

[0042] B. Put the reaction solution in A in a water bath and react at 70°C for 4 hours to obtain a precipitate; purify the precipitate at 20°C for 60 hours and then perform centrifugation. The centrifuge speed is 4000r / min, and then The precipitate was washed with deionized water and ethanol.

[0043] C. The separated precipitate of B was dried in an oven at 60°C for 4 hours, and then calcined at 400°C for 3 hours to obtain zinc-doped indium oxide nanomaterials.

[0044] The obtained zinc-doped indium oxide was evenly coated on the surface of the ceramic tube, then aged at 300°C for 48 hours, soldered on the circuit board and directly tested for gas sensitivity, the results are shown in Figure 5-10 ....

Embodiment 3

[0046] A. Dissolve indium nitrate, zinc nitrate and hexamethylenetetramine in deionized water to prepare a solution with a concentration of 0.050mol / L, then mix these three solutions at a volume ratio of 1:0.01:1, and ultrasonically After 15 minutes, the reaction solution was prepared.

[0047] B. Put the reaction solution in A in a water bath and react at 70°C for 4 hours to obtain a precipitate; purify the precipitate at 20°C for 66 hours and then centrifuge the centrifuge at a speed of 4000r / min. The precipitate was washed with deionized water and ethanol.

[0048] C. The separated precipitate of B was dried in an oven at 60°C for 4 hours, and then calcined at 400°C for 3 hours to obtain zinc-doped indium oxide nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com