Refrigeration-type coaxial packaging light-emitting tube core

A launch tube and coaxial technology, which is applied in the field of coaxially packaged light emitting die, can solve the problems of complex manufacturing process, signal distortion and high cost of cooling type coaxial packaged light emitting die

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

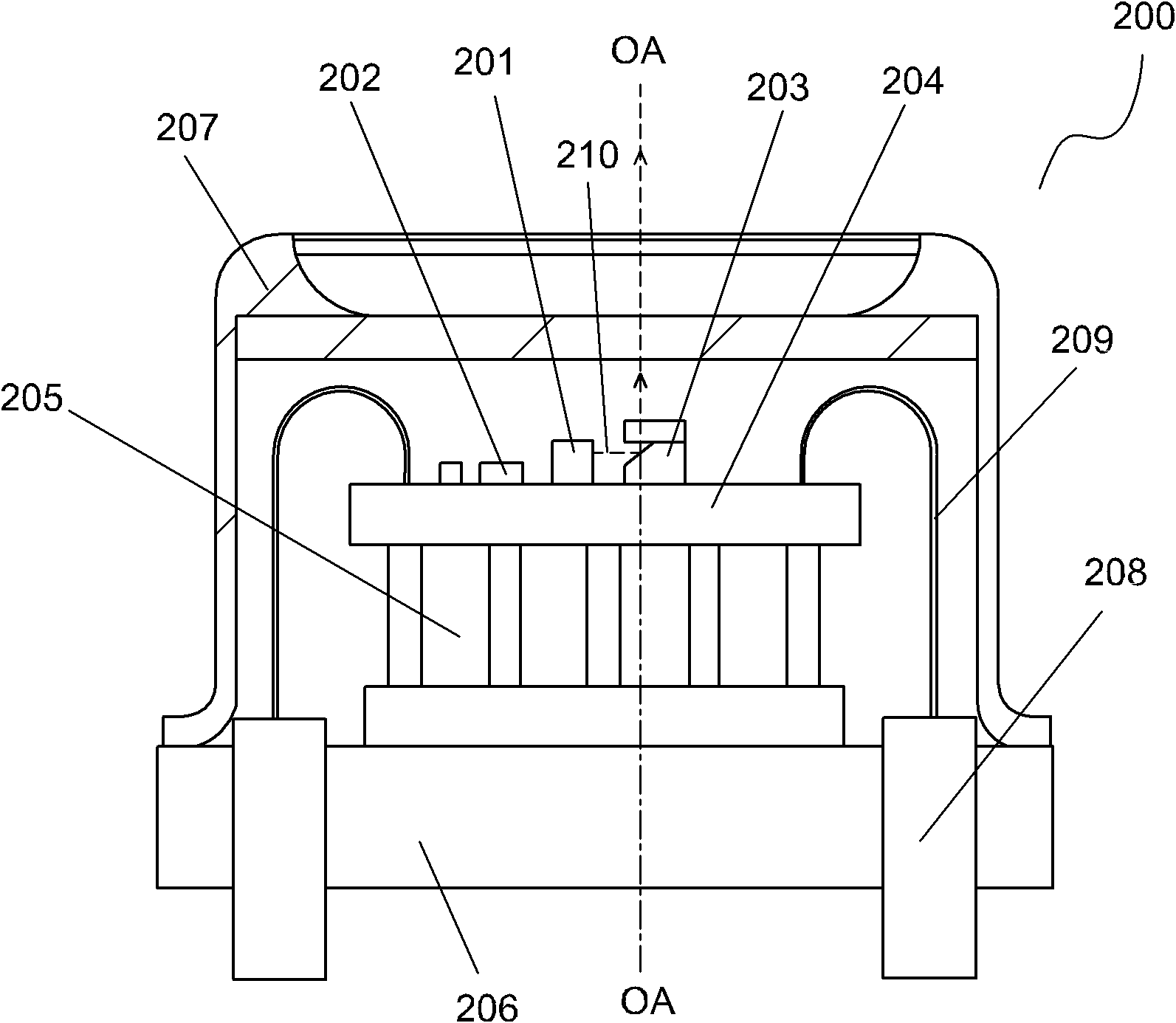

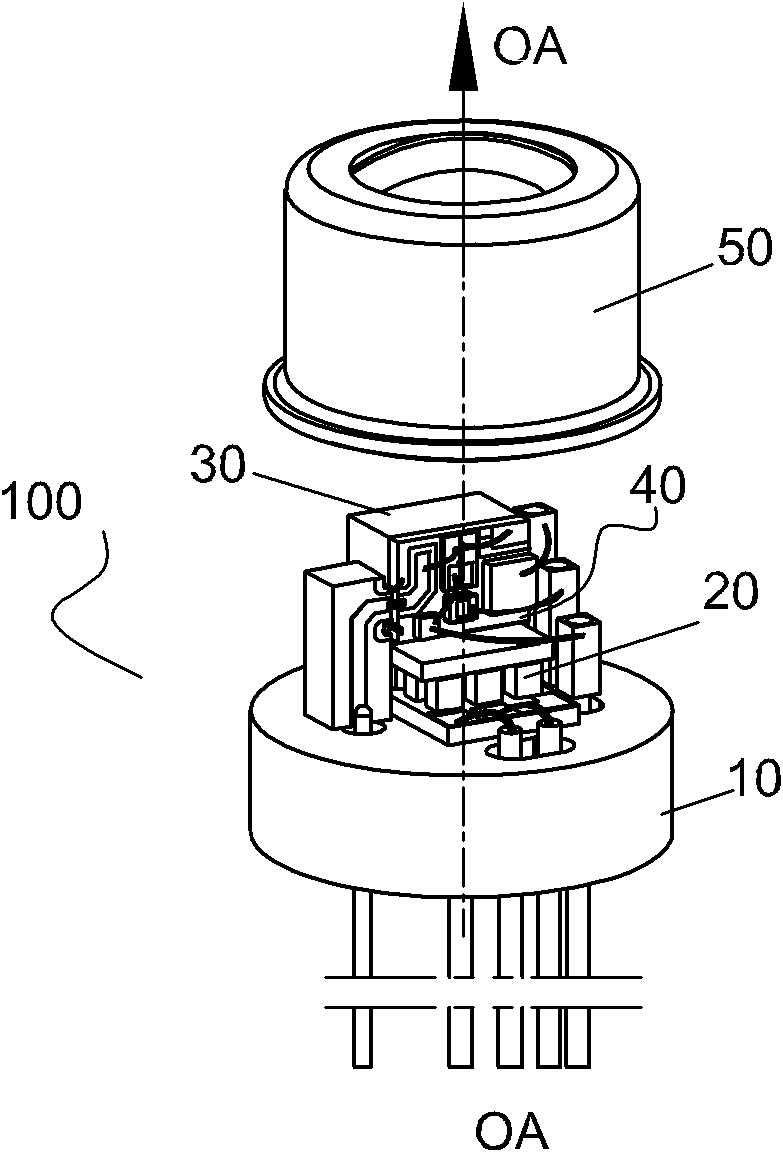

[0016] Such as figure 2 The cooling type coaxial package light emitting die 100 shown includes: a tube case 10, a uniform cooler 20, a heat sink 30, a laser carrier 40, and a sealed tube cap 50 provided with a light window. The cap can be a flat window cap, or a cap equipped with a spherical lens or aspheric lens. The cap lens is selected according to the different design of the coupling optical path. The outer surface of the optical window is coated with a reflective film to reduce the reflection of light. The influence of the laser.

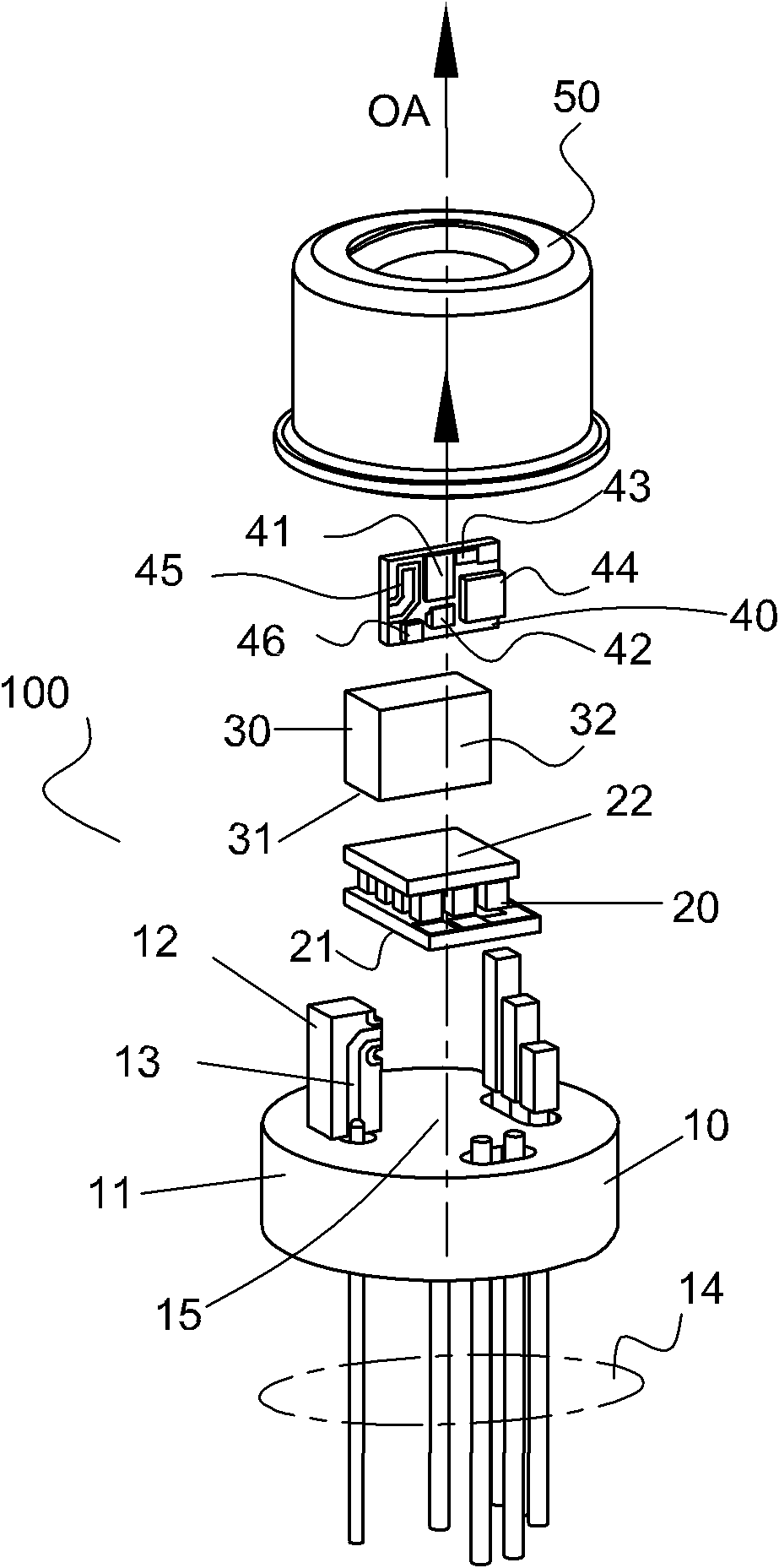

[0017] Such as image 3 In the cooling type coaxial package light emitting die 100 shown, the TO package 10 includes a package base 11 with at least 7 pins 14 around it, including an RF radio frequency signal pin, on which is mounted A carrier 12 with a microstrip line 13. The lower surface of the refrigera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com