Cement mixing pile with stiffness core capable of draining and pre-pressing firstly and then grouting as well as construction method thereof

A technology of cement mixing pile and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, soil protection, etc., to achieve the effect of low cost, enlarged depth and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

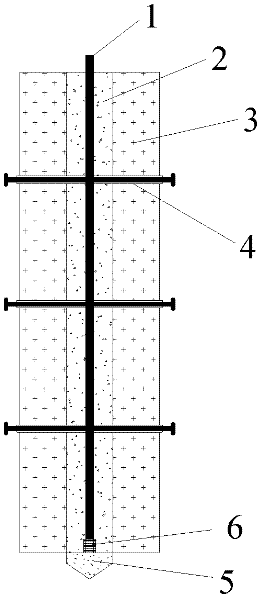

[0039] figure 1 It is a schematic cross-sectional view of the cement mixing pile with grouting core after drainage and preloading in the present invention, refer to figure 1 As shown, a grouting cored cement mixing pile with drainage and preloading first, including cement mixing pile 3, vertical drainage grouting pipe 1 arranged in cement mixing pile 3 and vertical drainage grouting pipe 1 arranged at intervals On the top, more than one double-layer horizontal drainage grouting pipe 4, a loose material core pile 2 is arranged in the cement mixing pile 3, and a prefabricated pile tip 5 is arranged at the bottom of the vertical drainage grouting pipe 1.

[0040] The vertical drainage grouting pipe 1 is a seamless steel pipe with an outer diameter of 30mm and a wall thickness of 2mm, and the pipe body is uniformly provided with drainage grouting holes.

[0041] The cement mixing pile 3 is a wet two-way cement mixing pile with a diameter of 0.6m. The pile length is 15m. Stir t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com