Patching and repairing method for local damage of carbon-fiber reinforced resin base laminating plate

A technology of reinforced resin and carbon fiber, which is applied in the field of local damage repair of carbon fiber reinforced resin-based laminates, can solve the problems of high cost, damage, and instability, and achieve the effect of small weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

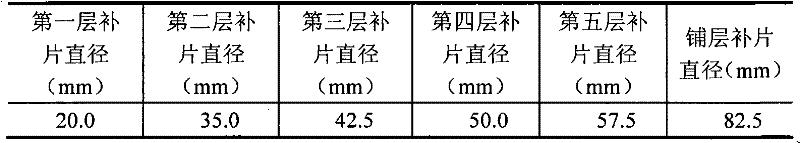

[0015] Example 1: Taking the carbon fiber reinforced resin-based laminate of brand T700 / 3234 as an example, the number of layers of the laminate 1 is 10, the thickness of each layer of prepreg is 0.125mm, and the thickness of the laminate film of brand SY24C is 0.125mm , the diameter of the damage defect is 20mm, the damage depth is 0.625mm for 5 layers, and the wedge angle is 1.909°.

[0016] The method for excavating and repairing local damage of the carbon fiber-reinforced resin-based laminate includes the following steps: digging out the damaged part of the carbon-fiber-reinforced resin-based laminate 1 layer by layer, using a rotary grinder for the excavation tool, and removing the prepreg layer by layer according to the depth of damage, the diameter of the damage, and the wedge shape. material to form the sunken area 2 to be repaired; then use a clean cloth to wipe off the dust and oil, prohibit the dust from spreading or embedding the surface, then wet the surface with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com