An external prestressed tension anchoring device and anchoring method for carbon fiber reinforcement

An external prestressing and anchoring device technology, applied in the field of bridge structures, can solve the problems of high tensile strength, good tensile performance, and inability to stretch carbon fiber bars, and achieve the effects of convenient production, fast installation and simple strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

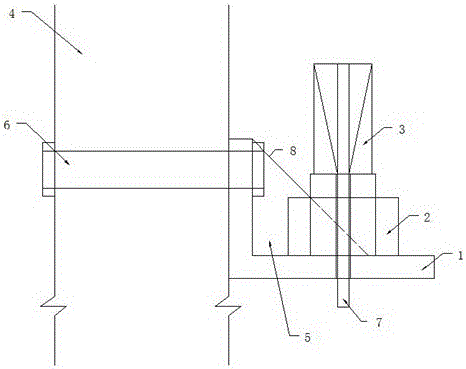

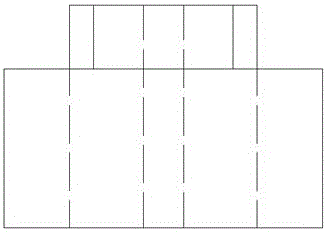

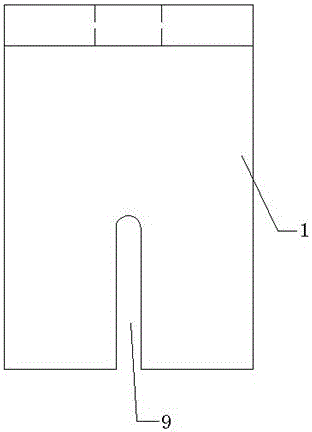

[0021] First introduce the structure of the tensioning device used in the present invention: as figure 1 and image 3 As shown, it includes a connecting device 5 fixed on the beam 4, a force applying device fixed on the connecting device 5, and a clip type anchor 3 arranged above the force applying device; the connecting device 5 fixed on the beam 4 Including L-shaped steel plate 1 and bolt 6, the L-shaped steel plate 1 is fixed on the beam 4 through the bolt 6 inserted in the beam 4 and the nut matched with the bolt 6 outside; the L-shaped steel plate 1 is provided with a U-shaped groove 9 The force applying device comprises a carbon fiber tendon 7, a double sleeve rotating device 2 that can be manually twisted and is arranged on the double sleeve rotating device 2 above the double sleeve rotating device 2, and is set on the carbon fiber tendon 7 and is used to clamp The clip-type anchorage 3 of the carbon fiber reinforcement, wherein the steel sheets 8 welded on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com