Lubricating oil pump for optimizing axial clearance

A technology for axial clearance and lubricating oil pumps, which is applied in lubricating pumps, engine lubrication, pumps, etc., can solve the problems of design and manufacture difficulties, increase the weight of lubricating oil pumps, and increase the axial clearance d

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

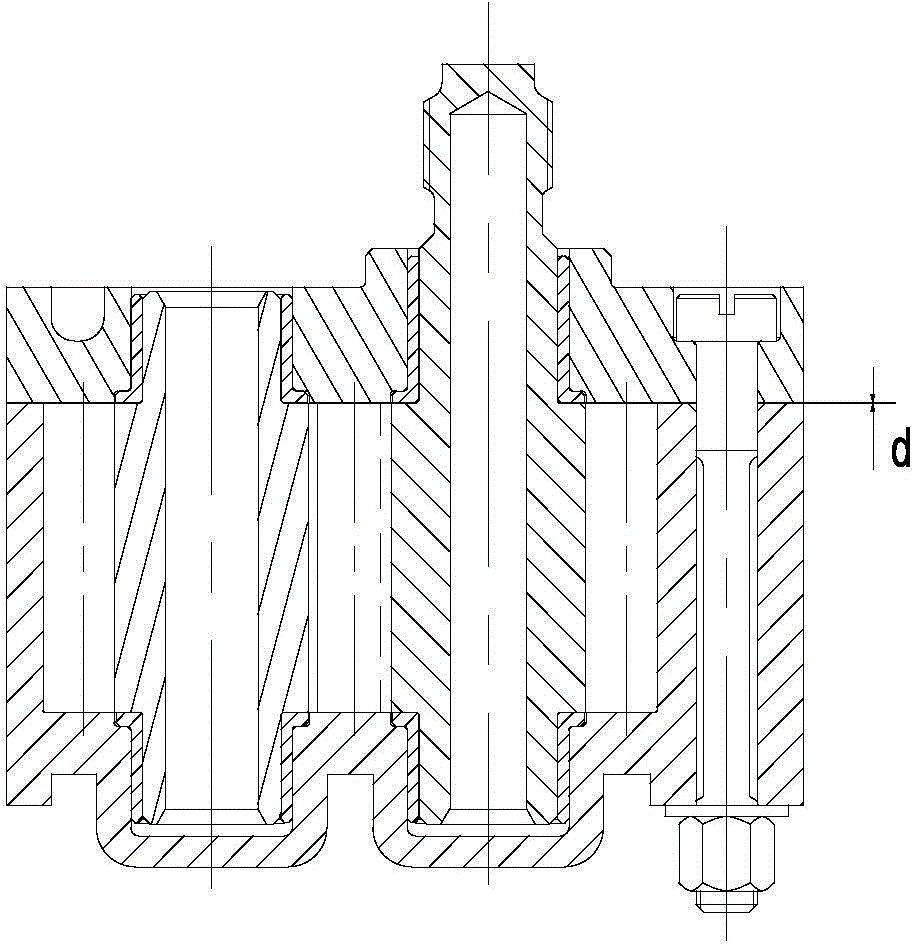

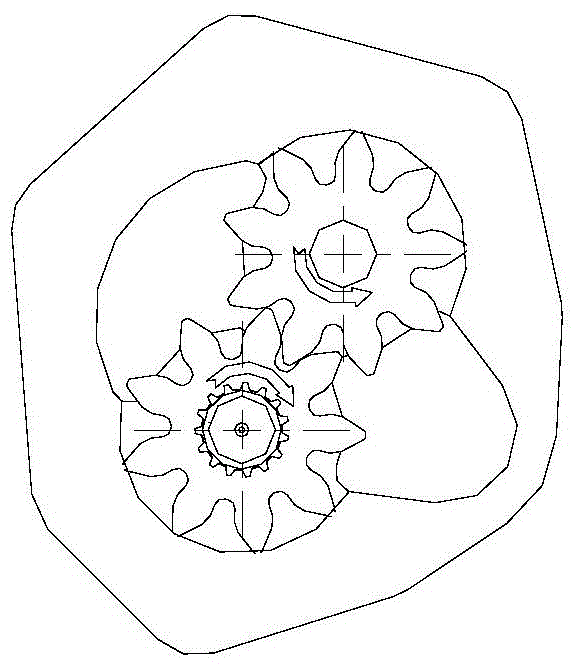

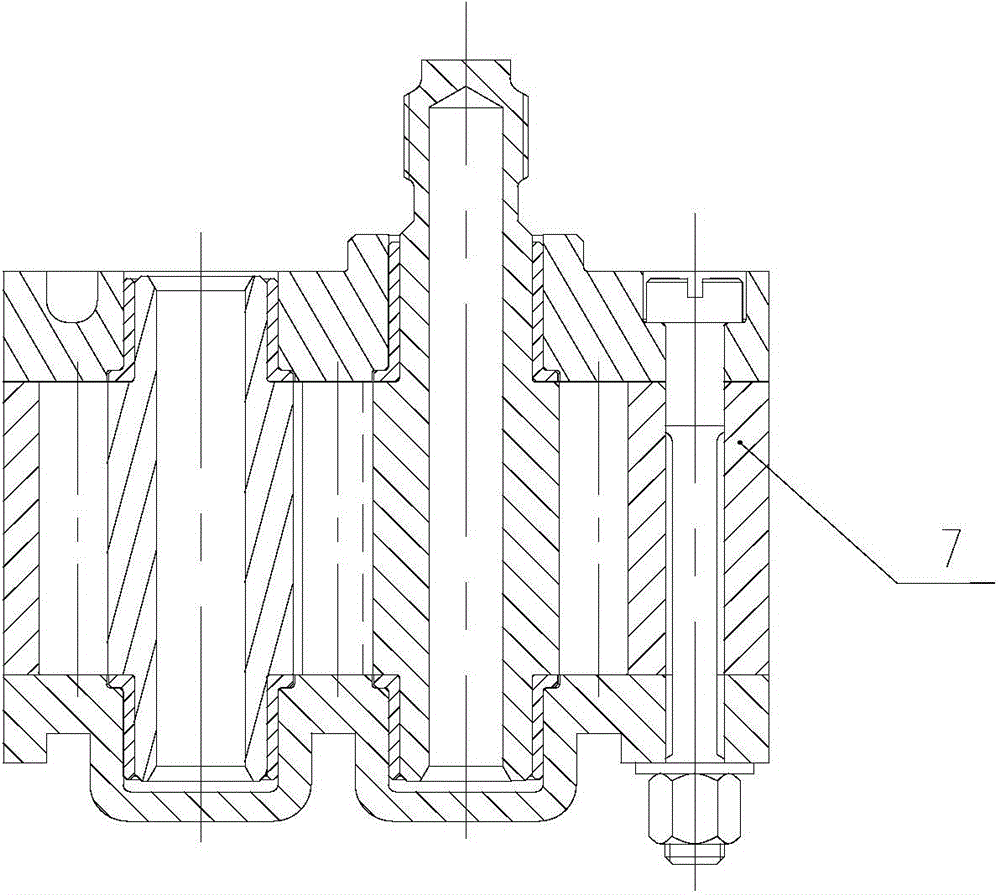

[0015] As shown in the figure, the lubricating oil pump with optimized axial clearance includes a pump body 3, a pump cover 2 and a rotor system 1. The rotor system 1 is located in a closed cavity formed by the pump body 3 and the pump cover 2. The pump body 3 and the pump A tapered washer 4 is also arranged between the covers 2. The tapered washer 4 is thick on the outside and thin on the inside. The linear expansion coefficient of the material is lower than that of the rotor system, such as low expansion alloy 4J32 alloy. The tapered washer 4 can be arranged at the position of the fastening bolt 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com