Industrial pollution whole process cooperative monitoring system and monitoring method adopting same

A monitoring system and a whole-process technology, applied in the energy industry, comprehensive factory control, comprehensive factory control, etc., can solve the problems of limited monitoring range, difficult to guarantee data quality, and inability to effectively play a role, so as to ensure accuracy and monitor data full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The collaborative monitoring system for the whole process of industrial pollution provided by the present invention and the monitoring method using the system are described in detail below in conjunction with the accompanying drawings:

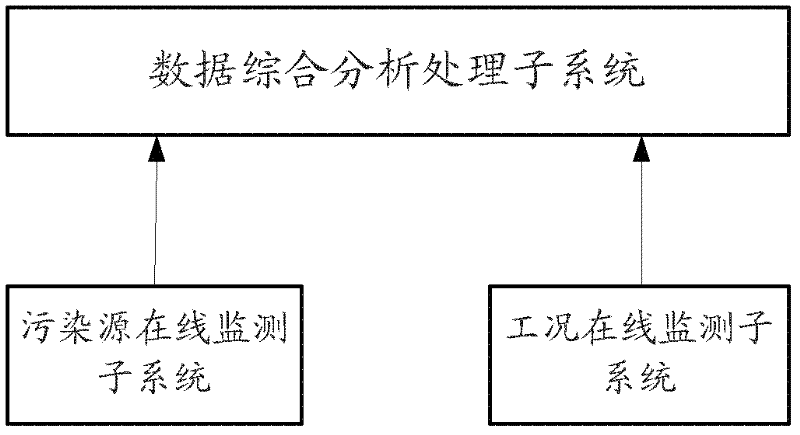

[0029] Such as figure 1 As shown, the present invention provides a collaborative monitoring system for the whole process of industrial pollution, including: an online pollution source monitoring subsystem, an online working condition monitoring subsystem, and a comprehensive data analysis and processing subsystem; wherein, the online pollution source monitoring subsystem and the The working condition on-line monitoring subsystem is respectively connected to the data comprehensive analysis and processing subsystem through a wired network and / or a wireless network.

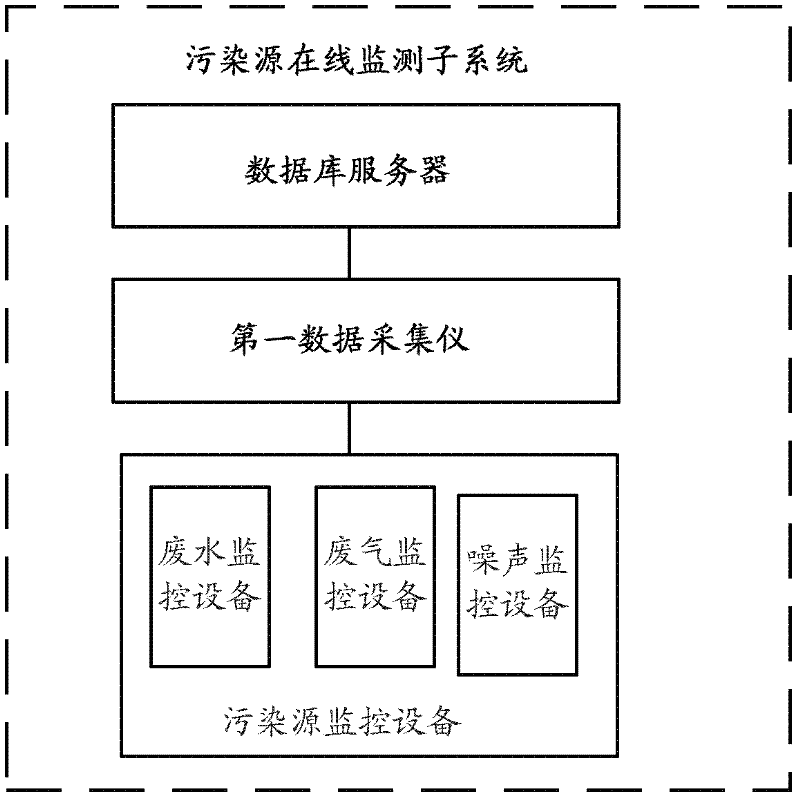

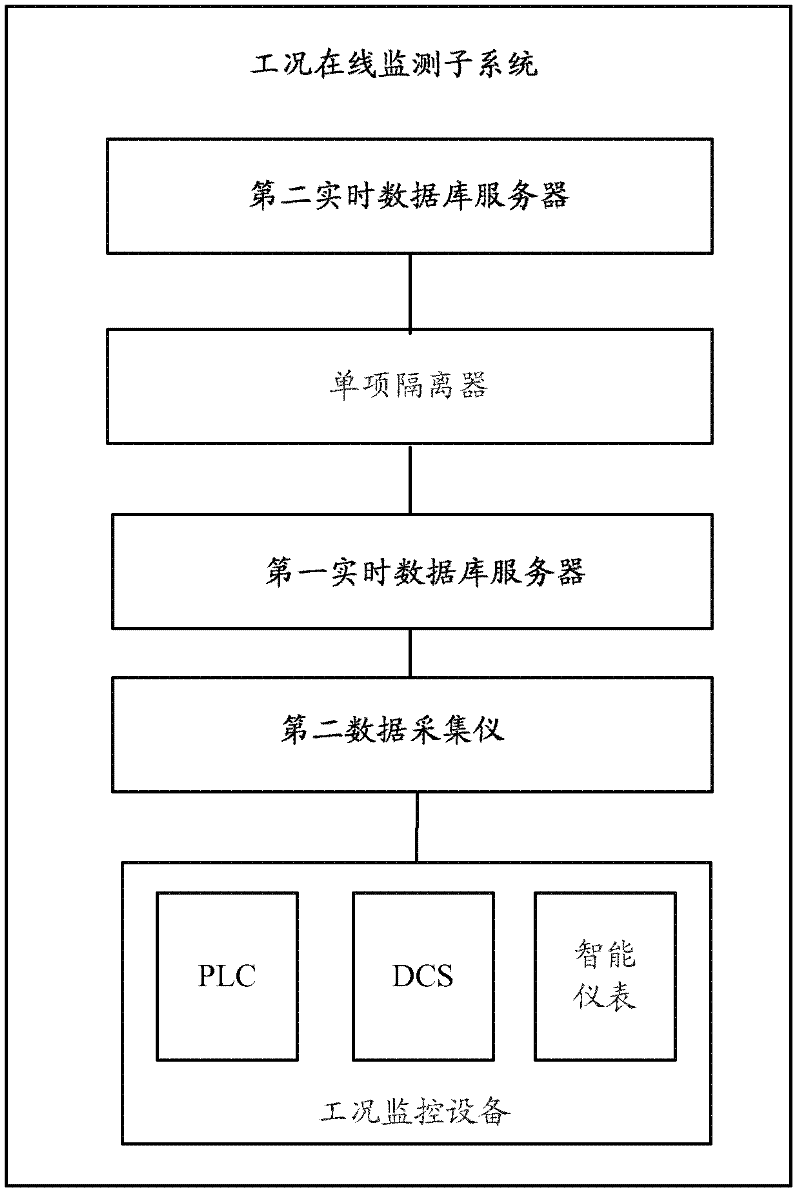

[0030] The following introduces the pollution source online monitoring subsystem, working condition online monitoring subsystem and data comprehensive analysis and processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com