Method for manufacturing color liquid crystal films, color liquid crystal film and display device

A technology of liquid crystal film and production method, applied in optics, instruments, nonlinear optics, etc., can solve the problems of low production efficiency, few color types, and difficulty in producing color liquid crystal films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention provide a method for manufacturing a color liquid crystal film, a color liquid crystal film, and a display device. A blue phase liquid crystal stabilized by a polymer is used to manufacture a color liquid crystal film, and an electric field is used to twist the liquid crystal to realize display of different colors. The liquid crystal is fixed by irradiation with ultraviolet light. Since the liquid crystal is twisted by the electric field, and the control of the electric field strength is much easier than the temperature control, it can improve the production efficiency of the color liquid crystal film, and it is also easy to control the color presented by the color liquid crystal film. In addition, by applying electric fields of different intensities, it is possible to fabricate colored liquid crystal films with a wide variety of colors.

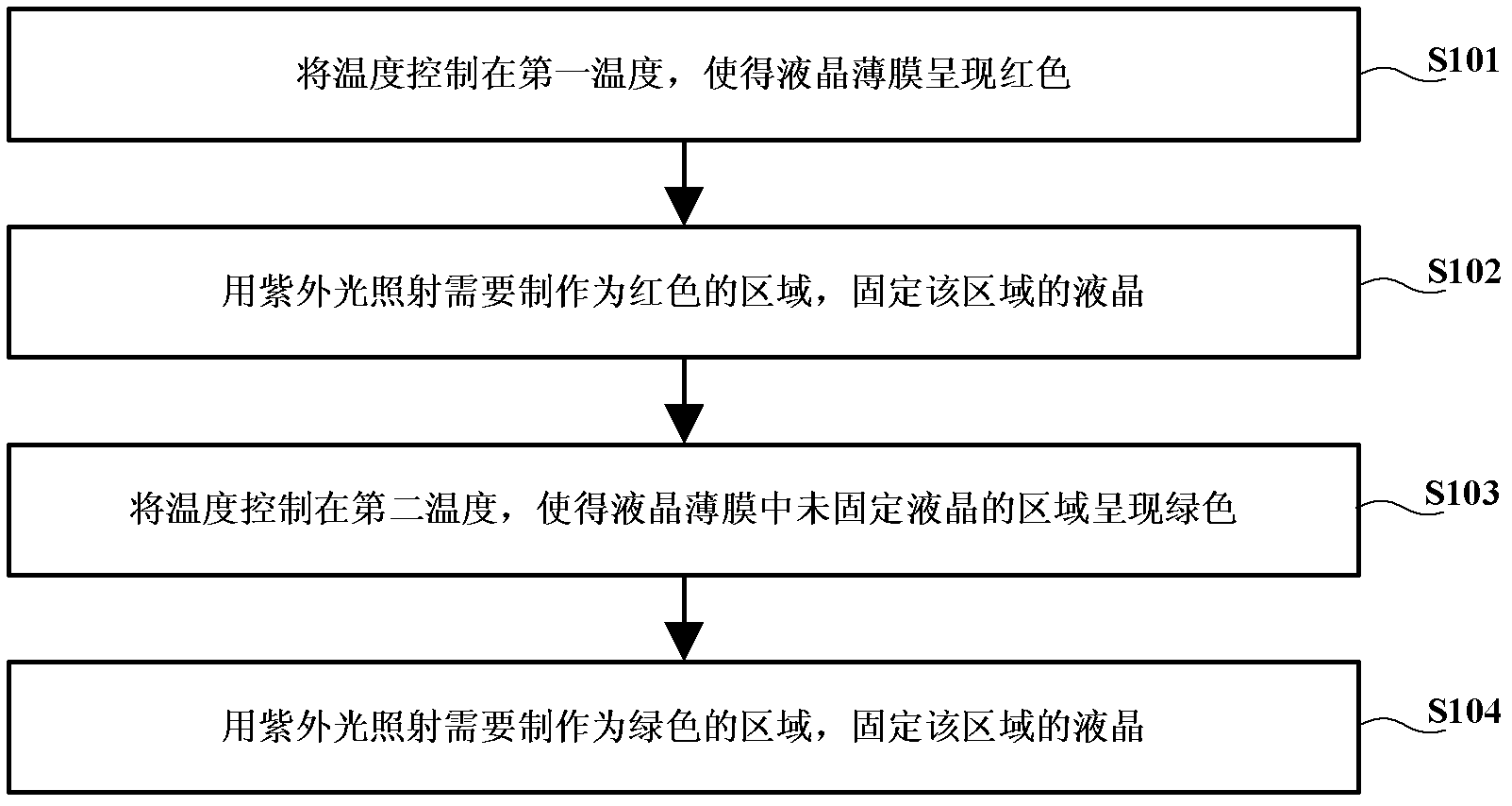

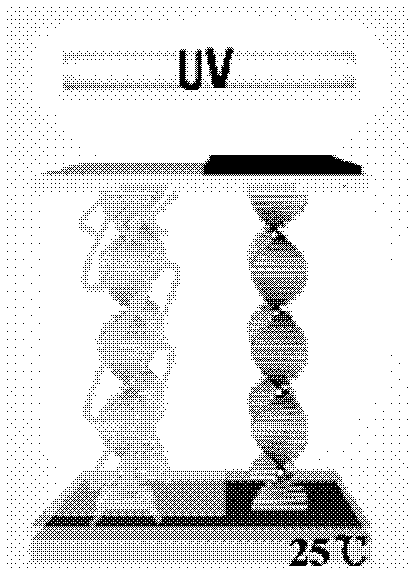

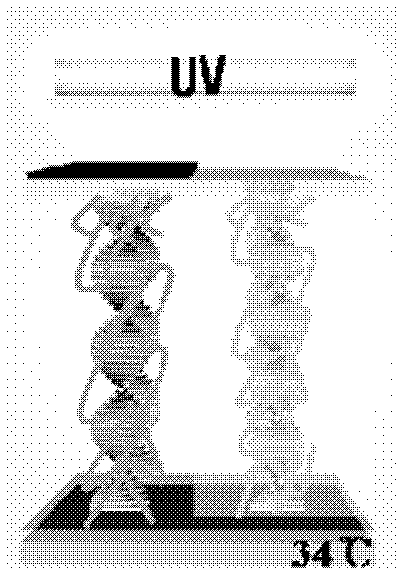

[0025] Such as Figure 4 As shown, the manufacturing method of the color liquid crystal film p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com