Novel knotted reactor (KR) desulfurization stirring method

A technology of agitator and stirring paddle, applied in the field of iron and steel metallurgy, can solve the problems of insufficient dynamic conditions of molten iron, poor dispersion effect of desulfurizing agent, short service life of stirring paddle, etc. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

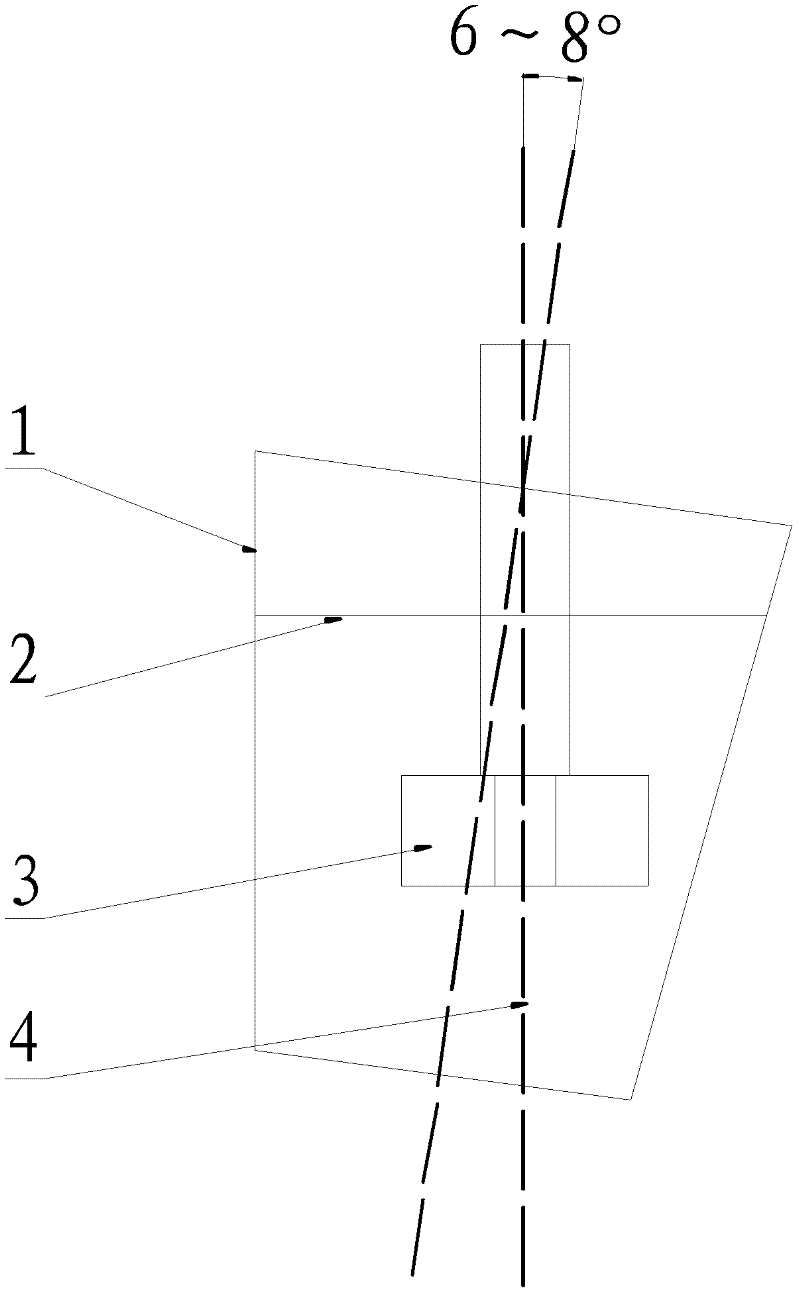

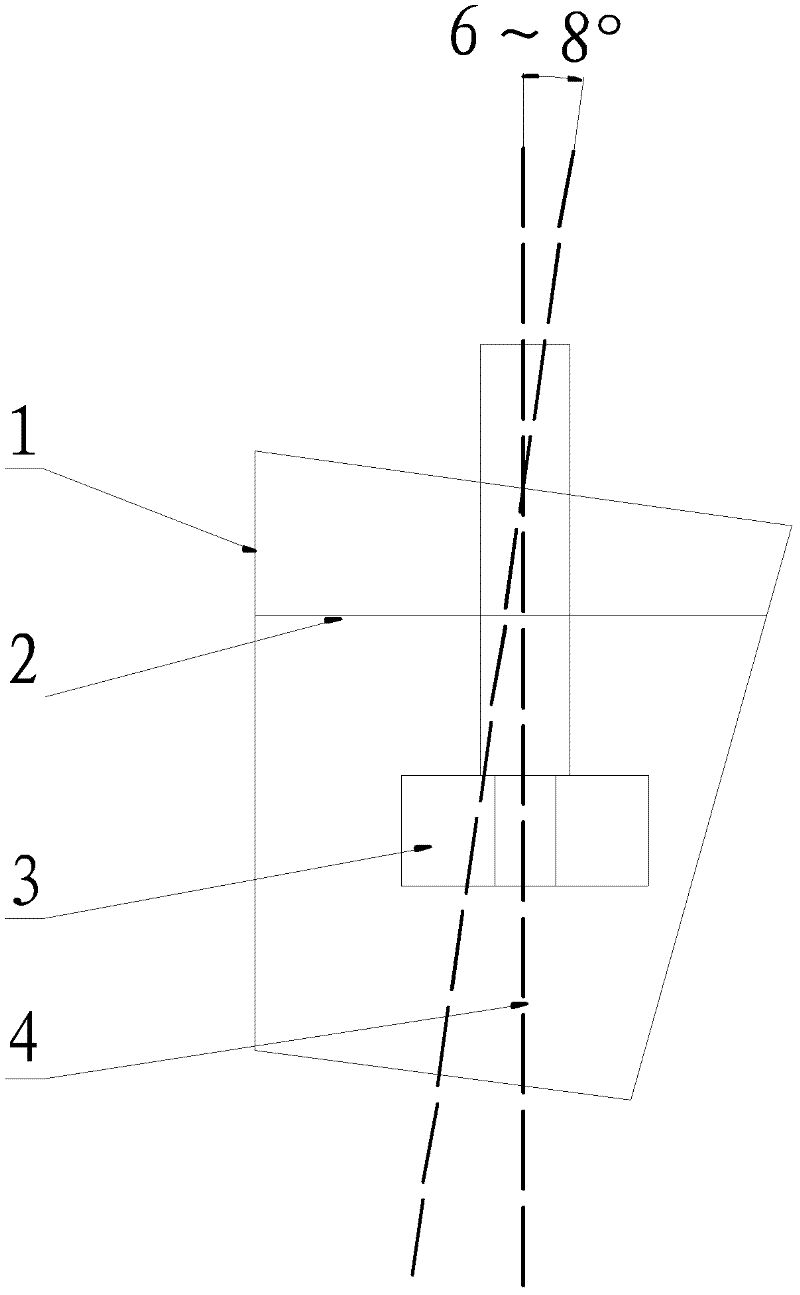

[0023] A stirring molten iron tank for rapid desulfurization, comprising a molten iron tank and an agitator, characterized in that the molten iron tank deviates from the vertical position by 6 to 8°; there is an agitator on the molten iron tank, and the stirring blade of the agitator is immersed in the iron in the molten iron tank in the water.

[0024] Such as figure 1 , the molten iron mechanical agitation desulfurization method of the present invention is that the molten iron tank 1 is tilted and placed, and its tilting angle deviates from the middle hammer axis line 4 of the tank body: 6 °, the stirring paddle 3 is immersed in molten iron for 1450 mm, and the agitator 3 The rotation and agitation of the molten iron make the desulfurization agent on the surface of the molten iron 2 involved in the molten iron, and a desulfurization reaction occurs to achieve the purpose of desulfurization.

Embodiment 2

[0026] Such as figure 1 , the molten iron mechanical agitation desulfurization method of the present invention is that the molten iron tank 1 is tilted and placed, and its tilting angle deviates from the middle hammer axis line 4 of the tank body: 7°, the stirring paddle 3 is immersed in the molten iron for 1200mm, and the agitator 3 The rotation and agitation of the molten iron make the desulfurization agent on the surface of the molten iron 2 involved in the molten iron, and a desulfurization reaction occurs to achieve the purpose of desulfurization.

Embodiment 3

[0028] Such as figure 1 , the molten iron mechanical agitation desulfurization method of the present invention is that the molten iron tank 1 is tilted and placed, and its tilting angle deviates from the middle hammer axis line 4 of the tank body: 8 °, the stirring paddle 3 is immersed in the molten iron for 1300mm, and the agitator 3 The rotation and agitation of the molten iron make the desulfurization agent on the surface of the molten iron 2 involved in the molten iron, and a desulfurization reaction occurs to achieve the purpose of desulfurization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com