Synthetic brake shoe and preparation method thereof

A technology for synthesizing brake shoes and nitrile rubber, which is applied in the field of transportation, can solve the problems that cannot reach 200,000-240,000 kilometers, and the service life of synthetic brake shoes is short, and achieve the advantages of small wheel wear, high yield and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

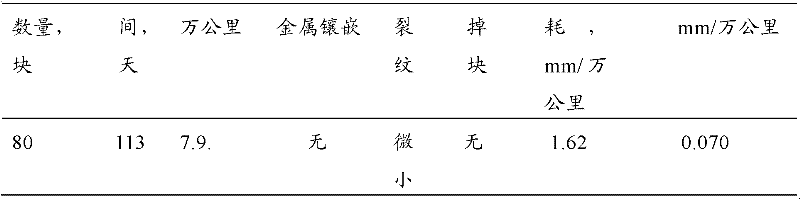

Image

Examples

Embodiment 1

[0038] Preparation of synthetic brake shoes

[0039] According to the formula composition, weigh the following raw materials:

[0040] 2123 phenolic resin: 3.9Kg, LG6250 nitrile rubber 2.49Kg, graphite 2.49Kg, reduced iron powder 4.53Kg, steel fiber 5.46Kg, wollastonite 2.49Kg, sepiolite MY-A type 3.6Kg, potassium feldspar 4.56Kg , 0.12Kg of alumina, 0.24Kg of sulfur, and 0.12Kg of accelerator CZ.

[0041] The above phenolic resin is a phenolic resin with a curing speed of 90 seconds / 160° C., a softening point of 110° C. and a free phenol weight content of less than 3%.

[0042] The nitrile rubber is nitrile rubber with acrylonitrile weight content of 34% and Mooney viscosity of (1+4) 100° C. 50.

[0043] The iron content of the reduced iron powder is 98% by weight of the iron powder, and the average fineness is 80 meshes;

[0044] The average length of the steel fiber is 8mm, and the average diameter is 0.1mm;

[0045] The average length of the sepiolite was 1 mm, the mois...

Embodiment 2

[0062] Preparation of synthetic brake shoes

[0063] According to the formula composition, weigh the following raw materials:

[0064] 2123 phenolic resin 5.0Kg, LG6250 nitrile rubber 3.50Kg, graphite 3.50Kg, reduced iron powder 5.50Kg, steel fiber 6.50Kg, wollastonite 3.50Kg, sepiolite MY-A type 4.5Kg, potassium feldspar 5.5Kg, Aluminum oxide 0.20Kg, sulfur 0.40Kg and accelerator CZ0.20Kg

[0065] The above phenolic resin is a phenolic resin with an average curing speed of 80 seconds / 160° C., a softening point of 110° C. and a free phenol weight content of less than 2%.

[0066] The nitrile rubber is nitrile rubber with an average acrylonitrile weight content of 31% and a Mooney viscosity of (1+4) 100° C. 45.

[0067] The iron content of the reduced iron powder is 99% by weight of the iron powder, and the average fineness is 80 meshes;

[0068] The average length of the steel fiber is 10mm, and the average diameter is 0.15mm;

[0069] The average length of the sepiolite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com