Method for purifying resorcinol by means of continuous crystallization

A technology for resorcinol and crystallization, which is applied in the field of separation and purification of resorcinol, can solve the problems of reduced energy consumption for recovery and large energy consumption for solvent recovery, and achieves reduced operating costs, high purity and yield, and guaranteed stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

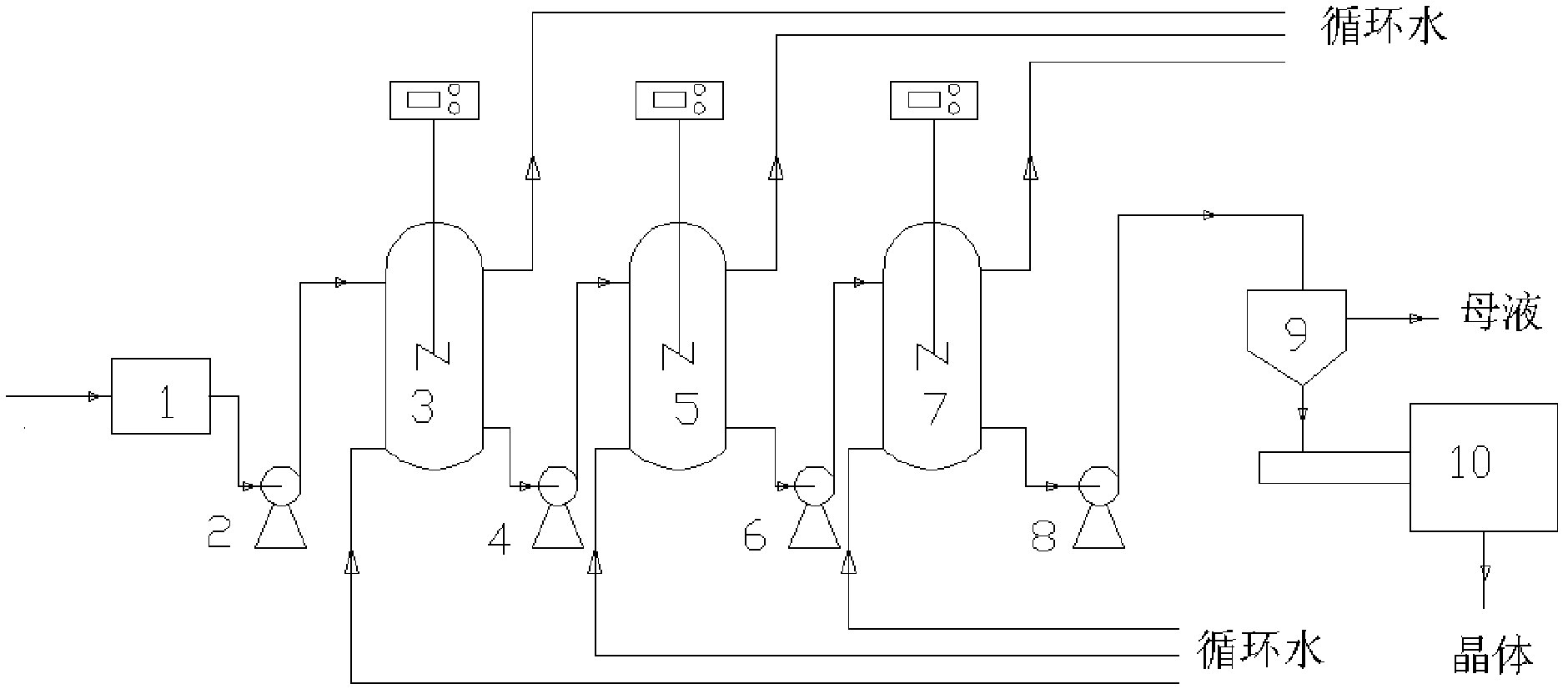

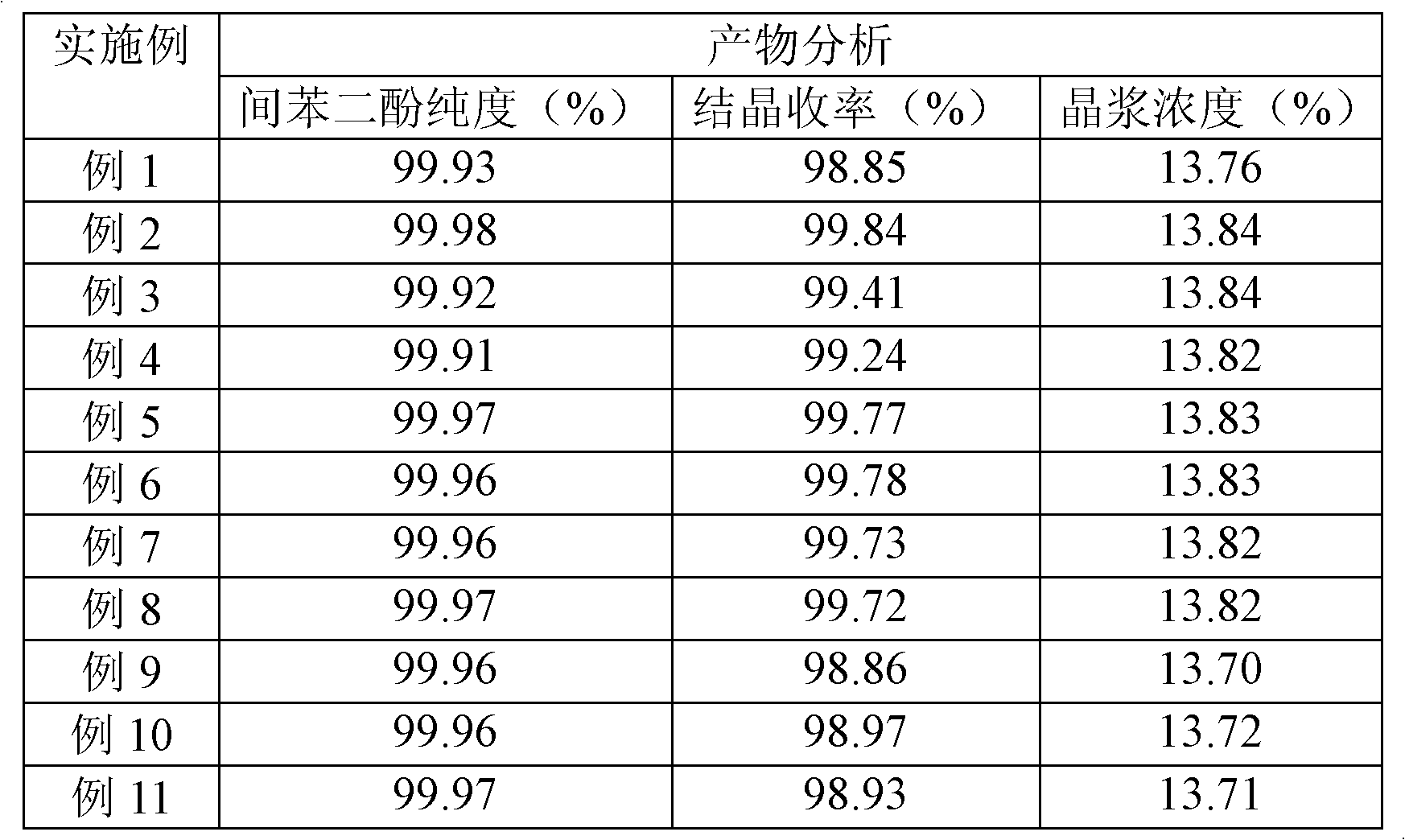

[0017] Add resorcinol crude product and toluene in dissolving device 1, wherein toluene and resorcinol crude product mass ratio are 6.05: 1, and resorcinol crude product purity is 97.79%, and temperature rises to 110 ℃, treats resorcinol After complete dissolution, the solution enters the crystallizer 3 through the pump 2, the temperature of the crystallizer 3 is 85°C, the stirring speed is 300r / min, and the residence time is 1h; then the crystal slurry enters the crystallizer 5 through the pump 4, and the temperature of the crystallizer 5 is 65°C , the stirring speed is 250r / min, the residence time is 1h; then the magma enters the crystallizer 7 through the pump 6, the temperature of the crystallizer 7 is 45°C, the stirring speed is 200r / min, and the residence time is 0.5h. Finally, the crystal slurry enters the solid-liquid separation device 9 through the pump 8 to complete the solid-liquid separation operation. The resulting mother liquor is analyzed by gas chromatography, a...

Embodiment 2

[0019] Add resorcinol crude product and toluene in dissolving device 1, wherein toluene and resorcinol crude product mass ratio are 6.05: 1, and resorcinol crude product purity is 97.79%, and temperature rises to 110 ℃, treats resorcinol After complete dissolution, the solution enters the crystallizer 3 through the pump 2, the temperature of the crystallizer 3 is 80°C, the stirring speed is 350r / min, and the residence time is 1.25h; then the crystal slurry enters the crystallizer 5 through the pump 4, and the temperature of the crystallizer 5 is 65 °C, the stirring speed is 300r / min, and the residence time is 0.75h; then the magma enters the crystallizer 7 through the pump 6, the temperature of the crystallizer 7 is 45°C, the stirring speed is 300r / min, and the residence time is 0.75h. Finally, the crystal slurry enters the solid-liquid separation device 9 through the pump 8 to complete the solid-liquid separation operation. The resulting mother liquor is analyzed by gas chroma...

Embodiment 3

[0021] The experimental device and operation are the same as in Example (1), except that the crystallization temperature of the crystallizer 7 is 40° C., the stirring speed is 250 r / min, and the residence time is 0.5 h. The experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com