Special compound clay fertilizer mould for plant cultivation and preparation method and applications of special compound clay fertilizer mould

A technology of compound soil and soil fertilizer, applied in application, fertilizer form, fertilization device, etc., can solve the problems of water and nutrients needed for plant growth, achieve good insect control effect, easy to penetrate growth, and reduce mountain torrents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

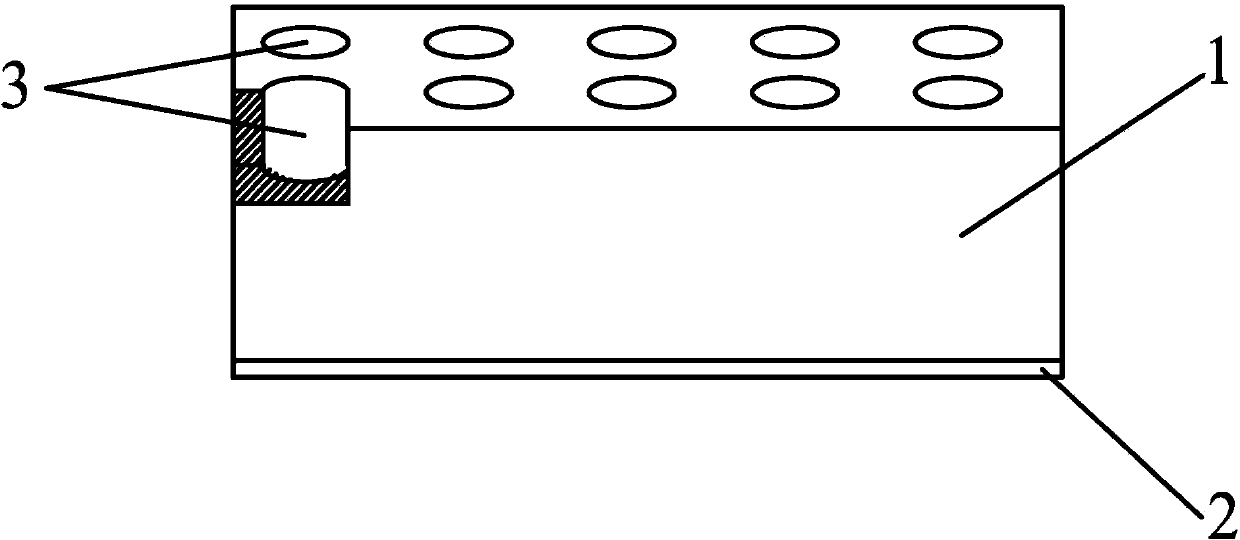

[0031]Embodiment 1 of the present invention: a kind of preparation method of the special compound soil fertilizer mold of plant cultivation, comprising: a. making steel mold; Powder 5 kg, farmyard manure 5 kg, trace elements boron and manganese 0.25‰ kg of compound soil mixed and prepared by crushing and sieving to 0.1 ~ 0.2 cm, and adding 10 kg of water to mix evenly, filling into the steel mold and stamping, stamping It can be simply squeezed by the strength of ordinary people; then take it out to get the hole 3 (such as figure 1 As shown), the composite soil fertilizer mold body 1 is dried; c. Take a commercially available composite plastic film, cut it according to the size of the bottom of the steel mold, and brush a layer of hydrated lime powder and glutinous rice slurry on the composite plastic film 2. The adhesive is obtained by lightly pressing the composite soil fertilizer mold body 1 on the above-mentioned adhesive and drying it in the air, wherein the holes 3 on th...

Embodiment 2

[0032] Embodiment 2 of the present invention: a special composite soil fertilizer mold for plant cultivation, comprising a composite soil fertilizer mold body 1 and a hole 3, the bottom of the composite soil fertilizer mold body 1 is bonded with a layer of composite waterproof membrane 2 with an adhesive; wherein: The composite soil and fertilizer mold body 1 is prepared by mixing 60 kg of pastoral soil, 5 kg of humus soil, 0.5 kg of superphosphate and 3 kg of farmyard manure. The specific preparation method is: a. making a wooden mold; b. crushing and sieving the composite soil prepared from pastoral soil, humus soil, superphosphate and farmyard manure, adding water and mixing it evenly, filling it into the mold, stamping and forming, and making holes 3. Then take out and obtain the composite soil fertilizer mold body 1, and dry it; c. Take the composite waterproof membrane 2 and cut it according to the size of the bottom of the mold, and brush a layer of adhesive on the compo...

Embodiment 3

[0033] Embodiment 3 of the present invention: a special composite soil fertilizer mold for plant cultivation, the specific preparation method is: a utilize cement to make concrete mold; The composite soil prepared by 8 kg of fertilizer, 8 kg of corn stalk powder, and 1‰ kg of trace elements is crushed, sieved, mixed evenly with water, filled into the mold, punched and formed, and the hole 3 is made, and then taken out to obtain the composite soil fertilizer mold body 1 , dry; wherein, the trace elements are: boron and manganese, they each account for 50%; c. take the composite waterproof membrane 2 and cut it according to the size of the bottom of the mould, and brush a layer of adhesive on the composite waterproof membrane 2, and apply the composite soil fertilizer The mold body 1 is lightly pressed on the adhesive and dried in the air; the shape of the composite soil fertilizer mold body 1 is triangular or polygonal.

[0034] In this embodiment, the adhesive is obtained by a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com