EPS (Expandable Polystyrene) lightweight aggregate concrete and preparation method thereof

A light aggregate concrete and raw material technology, which is applied in the field of concrete, artificial stone or ceramic products and their manufacture, and mortar, can solve the problems of EPS light aggregate concrete with many holes, difficult surface bonding, and EPS particles floating, so as to achieve maintenance The process is simple and easy to implement, reduces requirements, and is conducive to the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

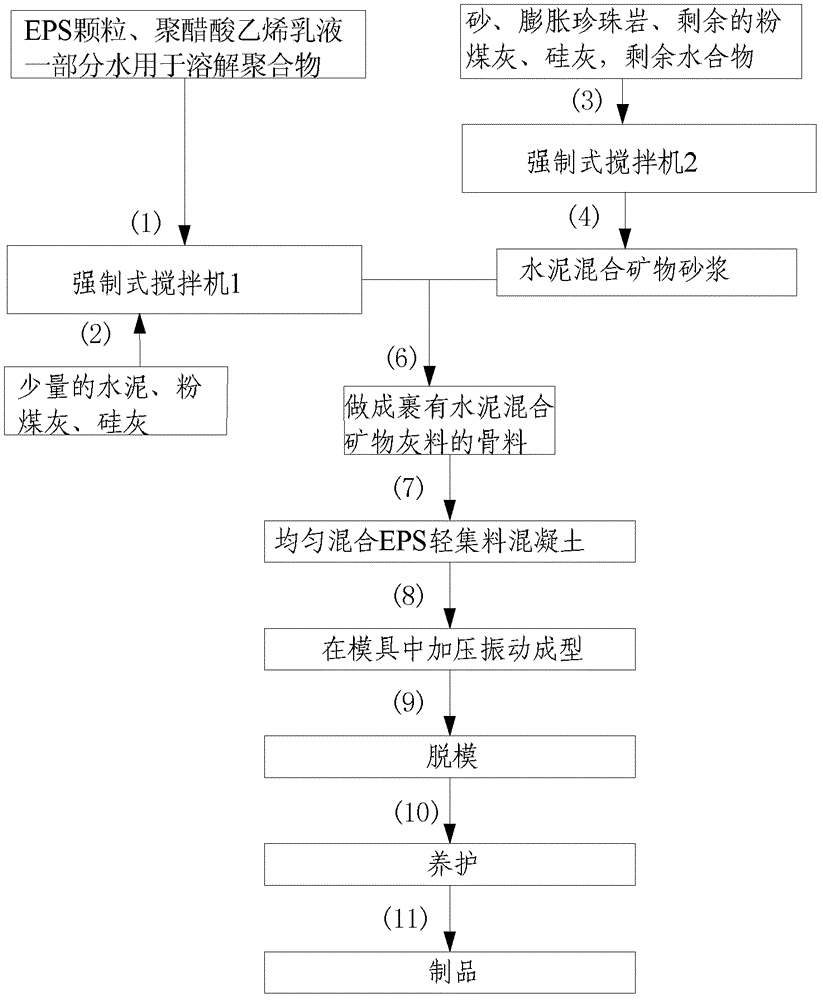

[0100] Preparation Technology of EPS Lightweight Aggregate Concrete

[0101] EPS particles are a material with very good thermal insulation properties. However, the special properties of this material will also bring some problems to concrete: first, the density of EPS particles is much smaller than that of fly ash cement mortar, and EPS particles are prone to float and material stratification during the mixing molding process; If the particle size of EPS particles is too large, it may cause relatively insufficient cement paste, resulting in more holes in EPS lightweight aggregate concrete. These two factors seriously reduce the uniform compactness of EPS lightweight aggregate concrete. The third is that EPS particles are an organic material with lipophilicity on the surface, while cement is an inorganic material mainly composed of ionic compounds, so its surface agglomerates have strong water absorption. The distinct surface properties of these two materials make their surf...

Embodiment 1

[0111] In this example, the ratio of selected raw materials is: 350 parts of cement, 110 parts of fly ash, 70 parts of silica fume, 127 parts of river sand, 198 parts of water, 15 parts of EPS particles, 40 parts of perlite, and 18 parts of polyvinyl acetate emulsion;

[0112] The particle size of silica fume is 0.1μm, and the density is 2.4g / cm 3 , bulk density 350kg / m 3 , specific surface area 25000m 2 / kg;

[0113] The river sand ratio is 20% by volume, and the bulk density is 1325kg / m 3 , the water absorption rate is 1.0%;

[0114] The density of EPS particles is 10kg / m 3 ;

[0115] Preparation Process:

[0116] shell making

[0117] Add the polyvinyl acetate solution together with a small amount of water, cement, silica fume and fly ash into the first forced mixer and stir into a paste;

[0118] Put the EPS particles into the first forced mixer and stir for 8 seconds, so that a thin layer of uniform cement-mixed mortar hangs on the surface of the EPS particles;

...

Embodiment 2

[0133] In this example, the ratio of selected raw materials is: 350 parts of cement, 90 parts of fly ash, 50 parts of silica fume, 120 parts of river sand, 190 parts of water, 18 parts of EPS particles, 50 parts of perlite, and 15 parts of polyvinyl acetate emulsion;

[0134] The particle size of silica fume is 0.15μm, and the density is 2.2g / cm 3 , bulk density 280kg / m 3 , specific surface area 20000m 2 / kg;

[0135] The river sand ratio is 22% by volume, and the bulk density is 1275kg / m 3 , the water absorption rate is 0.95%;

[0136] The density of EPS particles is 15kg / m 3 ;

[0137] Preparation Process:

[0138] shell making

[0139] Add the polyvinyl acetate solution together with a small amount of water, cement, silica fume and fly ash into the first forced mixer and stir into a paste;

[0140] Put the EPS particles into the first forced mixer and stir for 10 seconds, so that a thin layer of uniform cement-mixed mortar hangs on the surface of the EPS particles; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com