Positioning mechanism based on heat radiating tubes

A technology of positioning mechanism and heat dissipation pipe, which is applied in the direction of assembly machines, workbenches, metal processing equipment, etc., can solve the problems of extruding and ejecting heat dissipation belts, cumbersome installation steps, and low work efficiency, so as to achieve balanced assembly and positioning, and pipe layout Fast and convenient operation, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

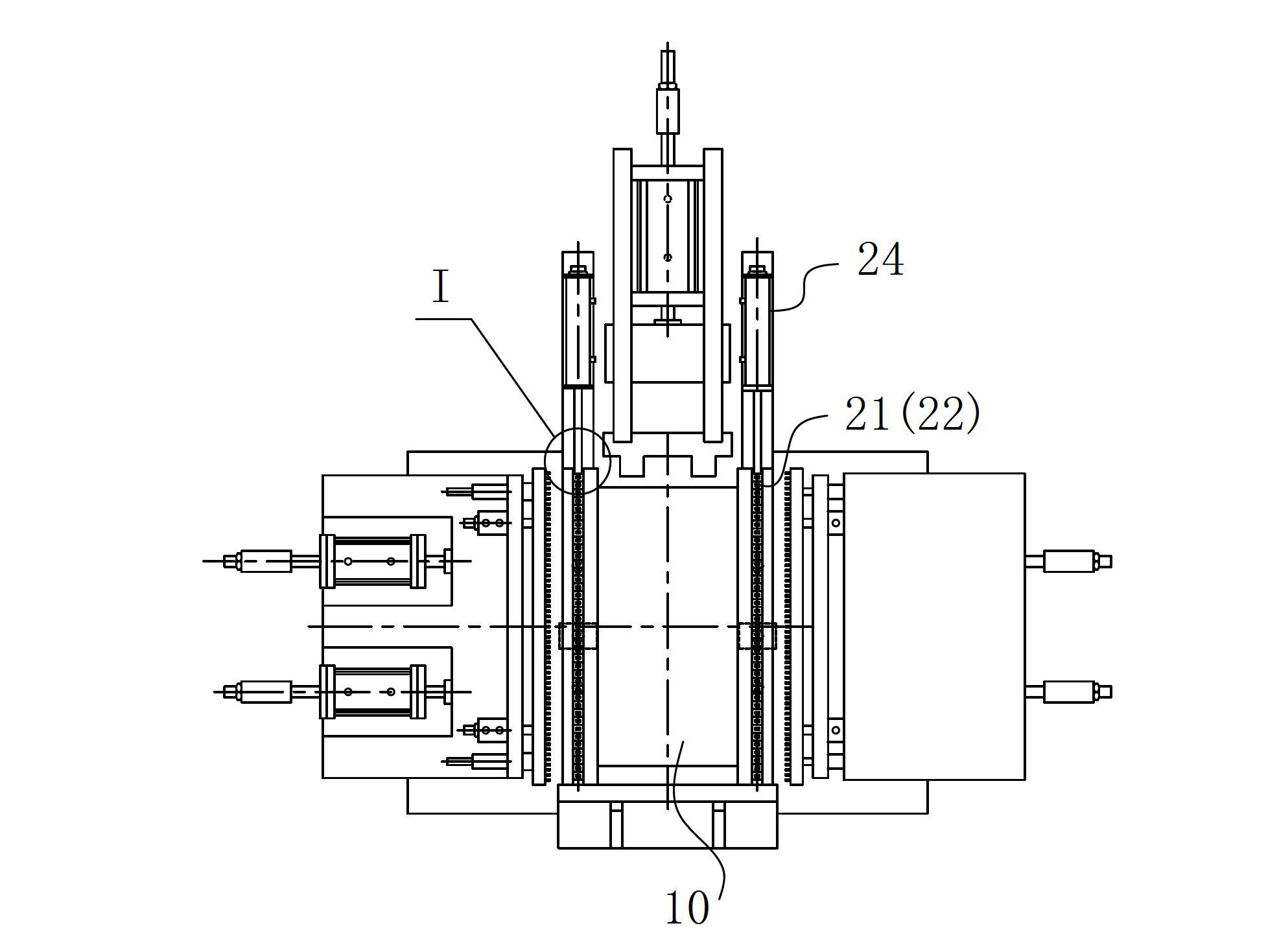

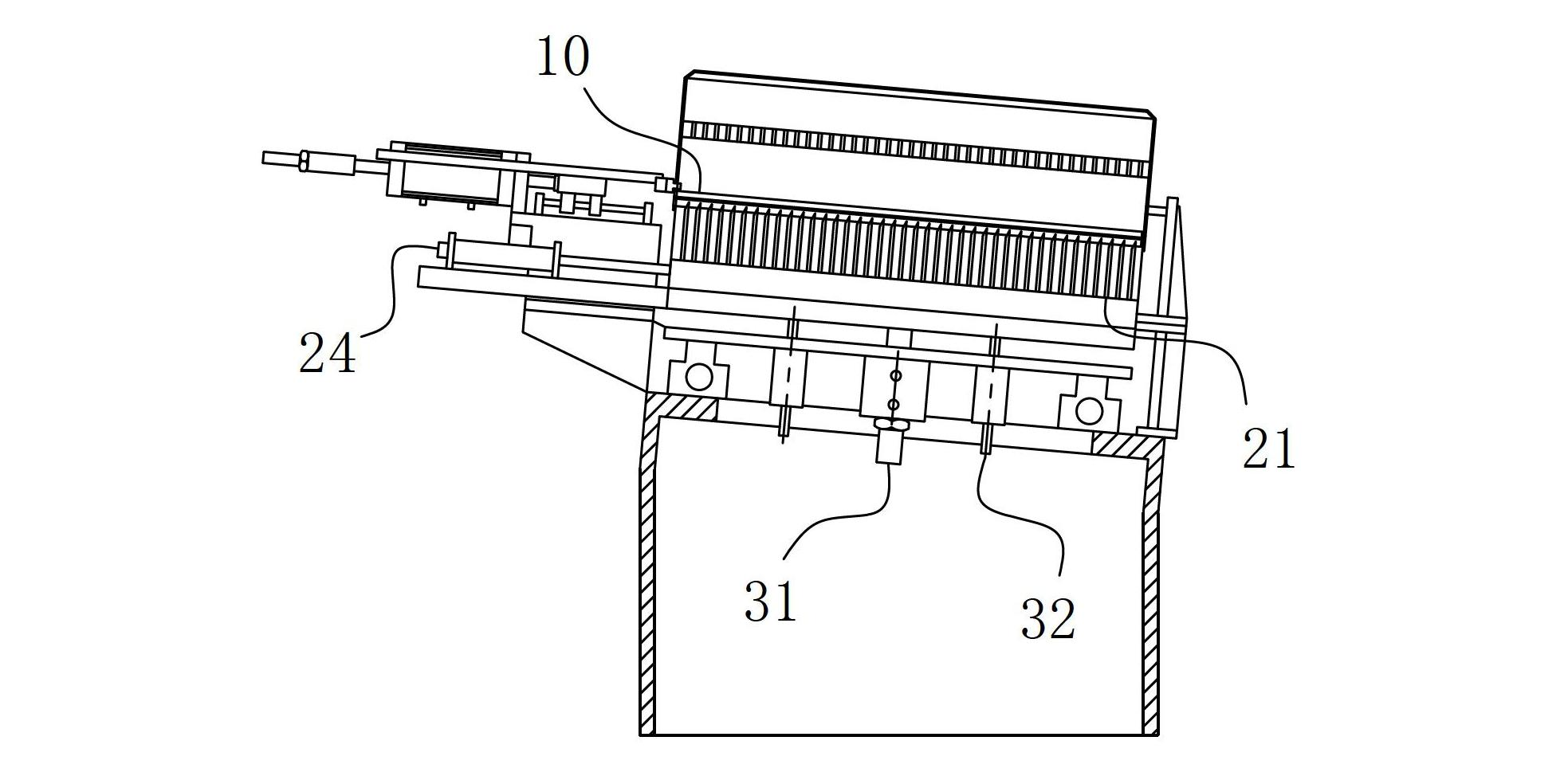

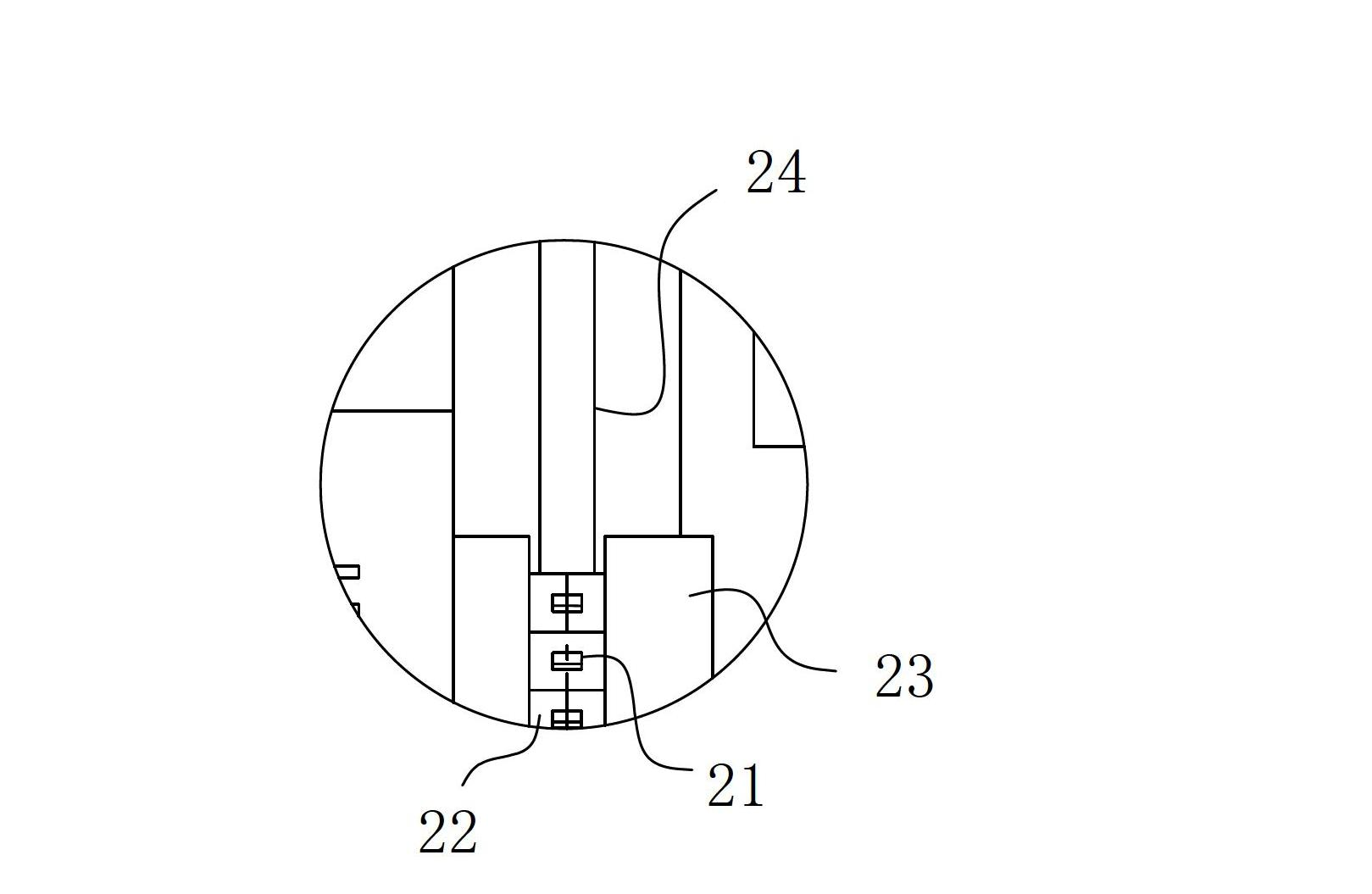

[0013] A positioning mechanism based on heat dissipation pipes, including a worktable 10 and a clamping unit for positioning and fixing the heat dissipation pipes arranged at least on one side of the worktable, the clamping unit includes a plurality of guide strips 21 arranged in parallel with each other The gap between the guide strips 21 constitutes the clamping interface on the clamping unit for positioning and fixing the heat dissipation pipe so that the plate surface is in an inclined or vertical direction. The arrangement direction of the guide strips 21 is set parallel to or intersects with the arrangement direction of the heat dissipation pipes, and the guide strips 21 have two position states of close together and outward expansion along the arrangement direction; when each guide strip 21 on the clamping unit is in the In the expanded state along its arrangement direction, the minimum distance between the card interfaces is greater than the bandwidth of the heat dissip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com