Cone locating and milling clamp for valve body

A valve body and fixture technology, applied in positioning devices, clamping, manufacturing tools, etc., to achieve the effects of ensuring processing quality, easy height adjustment, and accurate workpiece positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

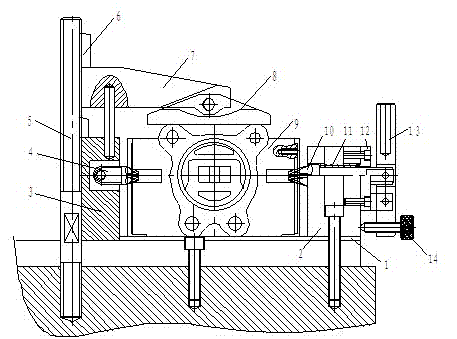

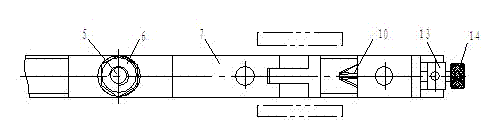

[0014] The left support seat 3 and the right support seat 2 are respectively at the two ends of the milling machine table, and the workpiece 9 is placed between the two support seats;

[0015] The left supporting seat 3 is threadedly connected with the screw rod 5, and is fixed on the machine tool workbench 1 through the screw rod 5, and a left thimble 4 is movably connected in the middle cavity, which is pushed in the left positioning hole of the workpiece 9;

[0016] The upper end of the screw rod 5 is threadedly connected with a connecting plate 7, and the front end of the connecting plate 7 is connected with a pressing plate 8. After the workpiece 9 is positioned, the nut 6 can be tightened to compress the workpiece 9;

[0017] The right thimble 10 is arranged in the middle through hole of the right bearing seat 2, pushes against the right positioning hole of the workpiece 9, and is movably connected with the connecting rod 13 through the middle through hole; a spring 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com