Clamping mechanism for fixing wiring harness

A technology of clamping mechanism and fixed line, which is applied in the direction of workpiece clamping device, circuit/current collector parts, manufacturing tools, etc., can solve the problems of inconvenient operation, poor clamping effect, and inability to adjust, and achieve convenient operation and clamping Good lasting effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

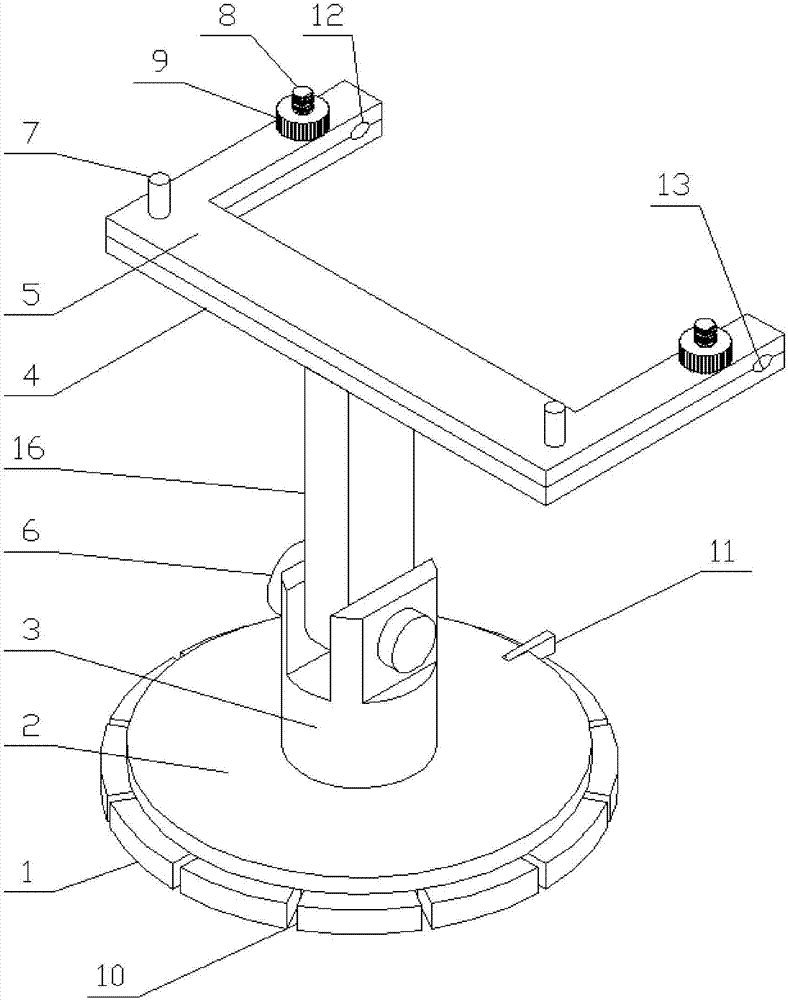

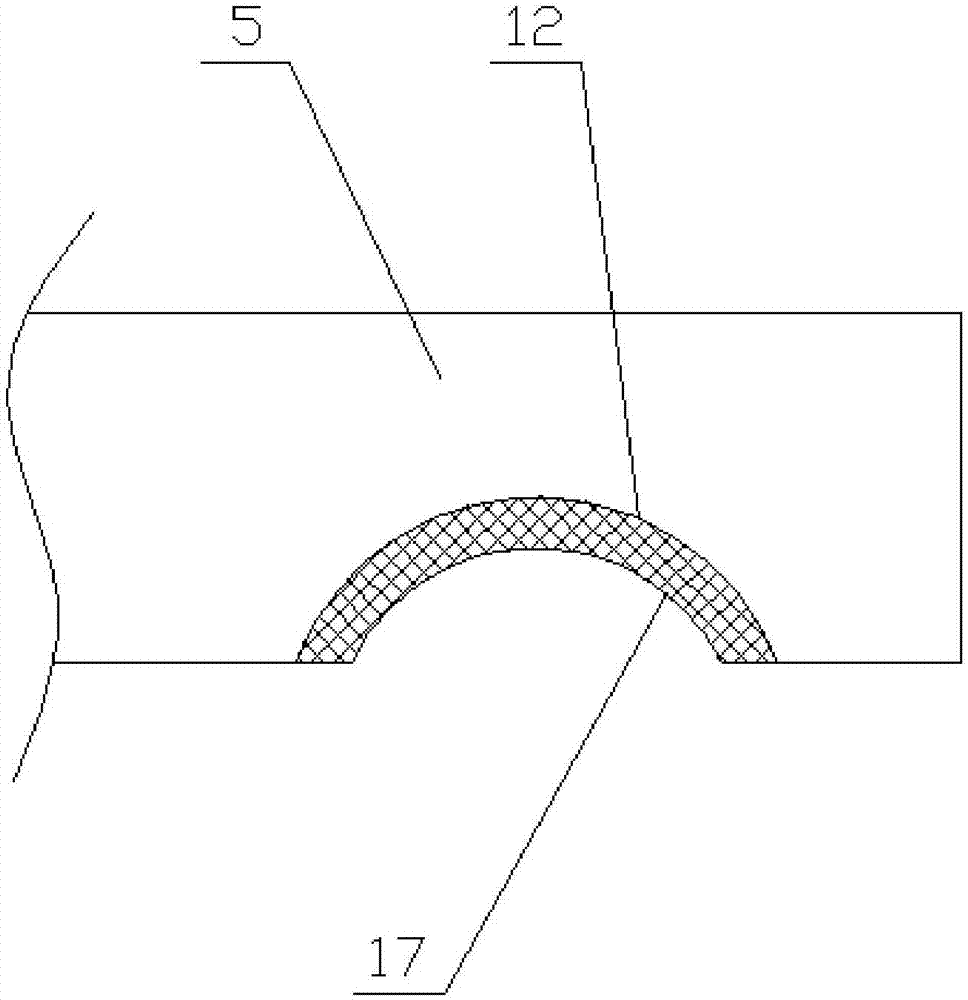

[0019] Such as Figure 1 to Figure 3 As shown, a clamping mechanism for fixing a wire harness includes a circular base 1, a disc 2, a hinged seat 3 and a clamping mechanism. The disc 2 is rotatably connected to the circular base 1 through a bearing. The hinged seat 3 is fixed at the center of the top of the disc 2, and the clamping mechanism includes a fixed splint 4 and a movable splint 5. The bottom of the fixed splint 4 is connected with a support seat 16, and the support seat 16 and the hinged seat 3 are locked together. The bolt 6 is connected, the movable splint 5 is installed on the fixed splint 4 through the guide mechanism 7, and the fixed splint 4 is U-shaped, and the fixed splint 4 is provided with bolts, and the movable splint 5 passes through the bolt and is fastened by a nut 9 .

[0020] In this embodiment, several notches 10 are provided at the edge of the circular base 1, the number of the notches 10 is at least three, and the notches 10 are arranged in a circ...

Embodiment 2

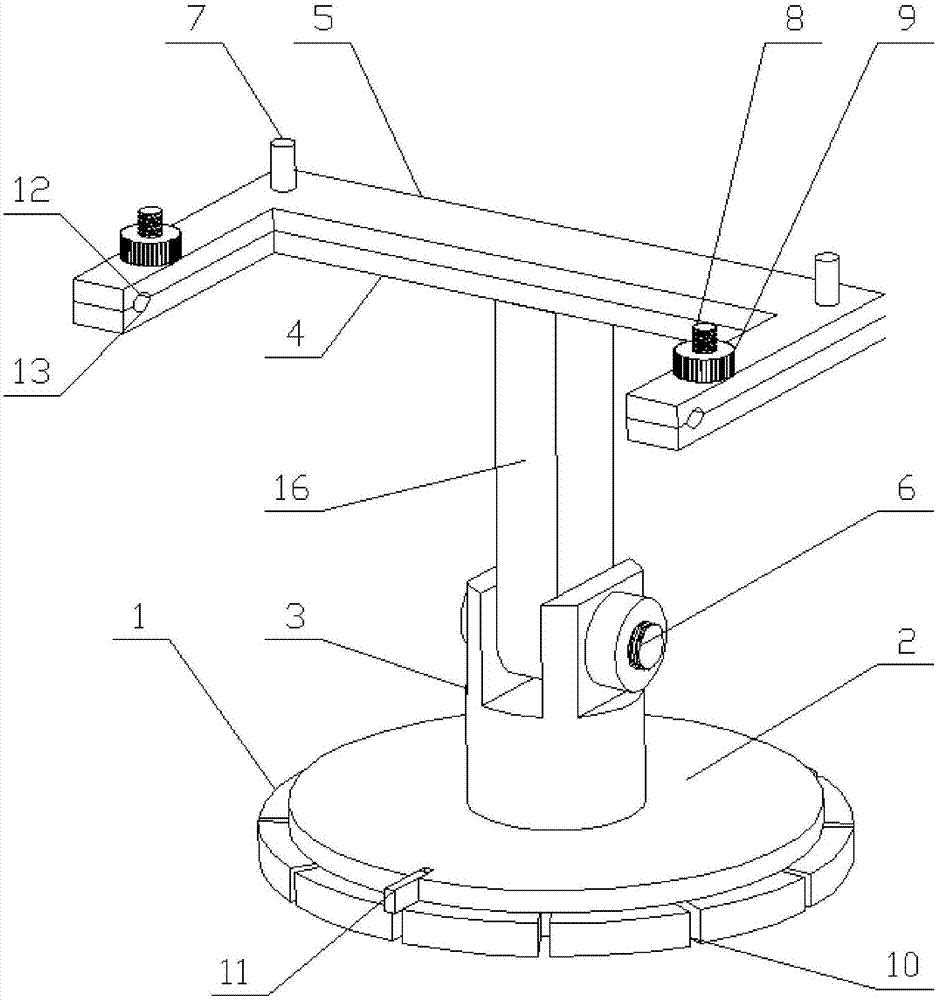

[0024] Such as Figure 4 and Figure 5 As shown, a clamping mechanism for fixing a wire harness includes a circular base 1, a disc 2, a hinged seat 3 and a clamping mechanism. The disc 2 is rotatably connected to the circular base 1 through a bearing. The hinged seat 3 is fixed at the center of the top of the disc 2, and the clamping mechanism includes a fixed splint 4 and a movable splint 5. The bottom of the fixed splint 4 is connected with a support seat 16, and the support seat 16 and the hinged seat 3 are locked together. The bolt 6 is connected, the movable splint 5 is installed on the fixed splint 4 through the guide mechanism 7, and the fixed splint 4 is U-shaped, and the fixed splint 4 is provided with bolts, and the movable splint 5 passes through the bolt and is fastened by a nut 9 .

[0025] In this embodiment, several notches 10 are provided at the edge of the circular base 1, the number of the notches 10 is at least three, and the notches 10 are arranged in a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com