Soft iron-brass composite band structure and welding method thereof

A technology of composite elastic belt and welding method, applied in welding equipment, warheads, ammunition and other directions, can solve the problems of restricting the belt, affecting the life of the gun body, and the rifling of the soft iron belt. Improve performance and functionality, increase the effect of charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

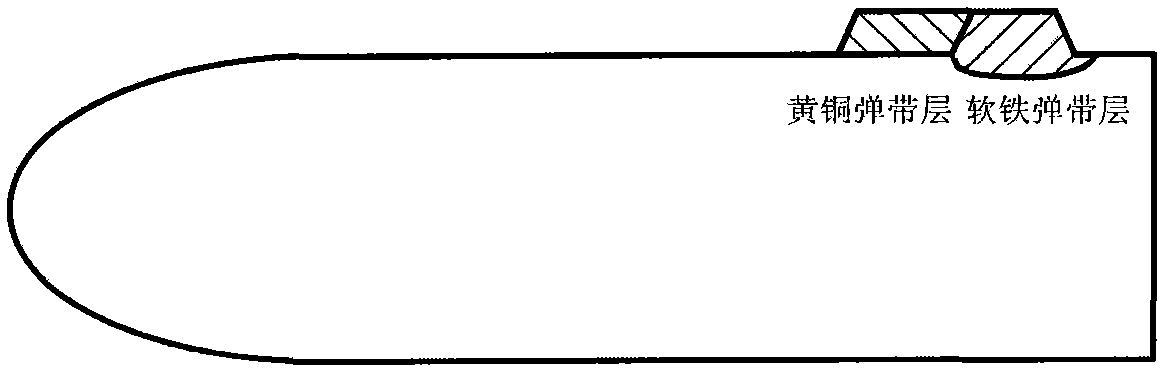

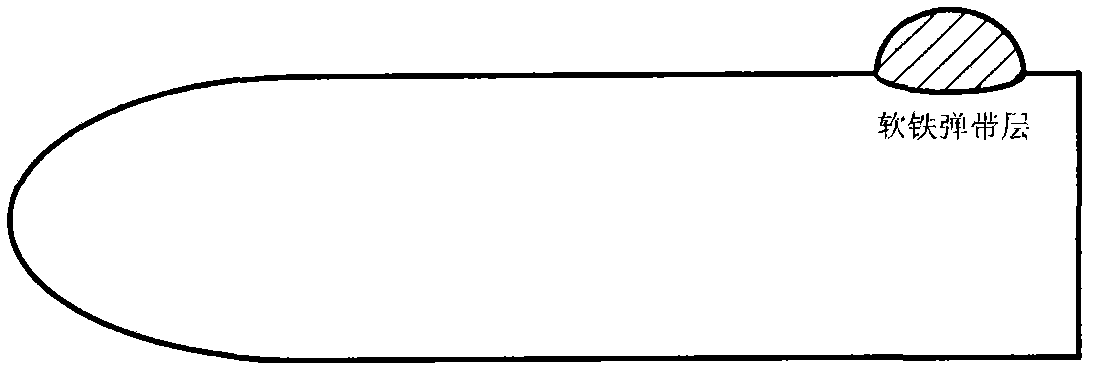

[0017] Example 1: Combining figure 1 , a soft iron-brass composite elastic belt structure of the present invention, two kinds of material are used for overlay welding to form elastic belt on the surface of the elastic body, wherein the soft iron part is located at the rear part of the elastic belt, and the brass part is located at the front part of the elastic belt.

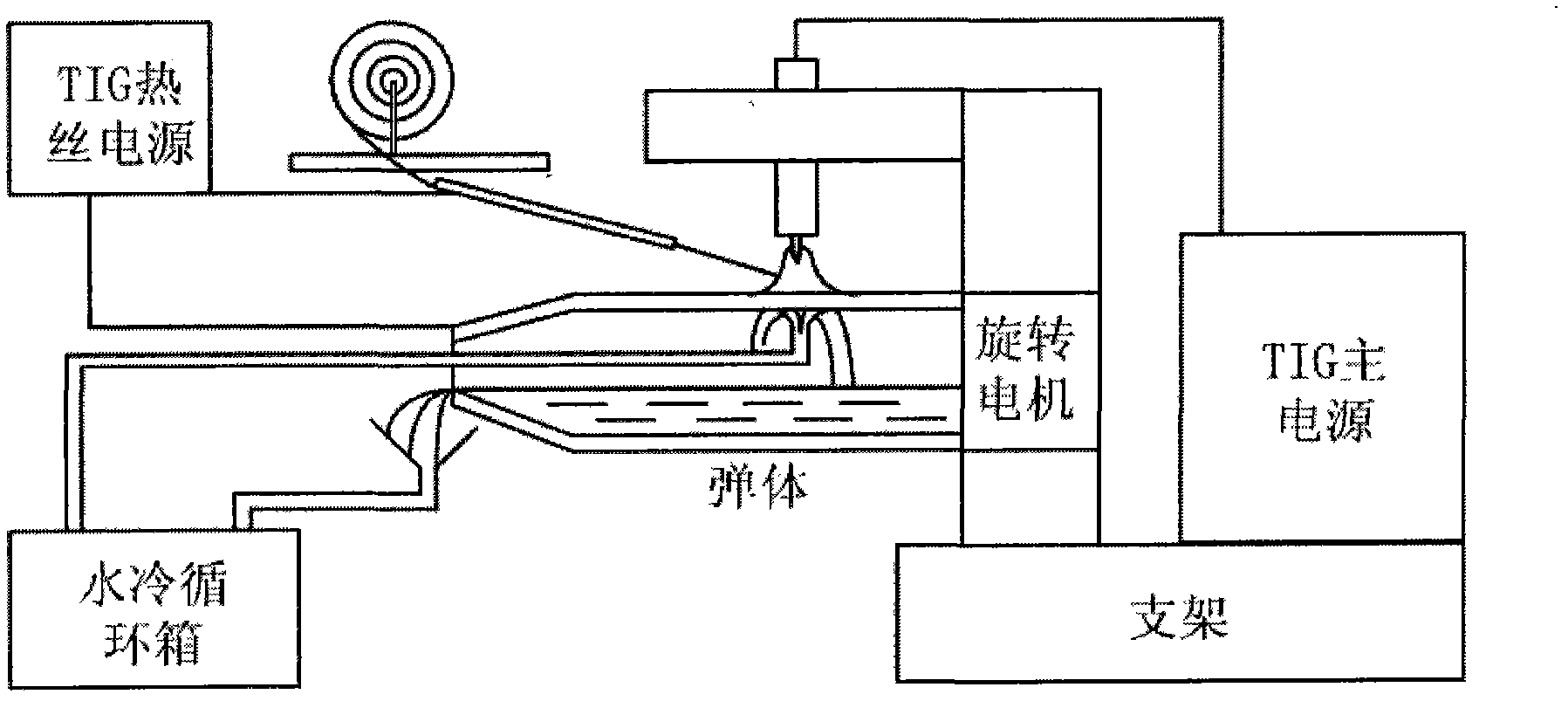

[0018]The invention relates to a welding method of a soft iron-brass composite elastic belt structure, which adopts tungsten argon arc welding, and arc hot wire semi-automatically feeds the elastic belt for welding, and connects the two electrodes of the auxiliary TIG power supply to the wire feeder respectively. On the nozzle and the workpiece, a conductive circuit is formed. When the welding process starts, the main welding circuit is connected, the main arc is ignited to preheat the workpiece for 1-2 seconds, and then the welding wire is fed through the wire feeding device. When the distance between the end of ...

Embodiment 2

[0019] Example 2: Combining figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , a soft iron-brass composite elastic belt structure and its welding method according to the present invention, the main feature is that the elastic belt adopts a welding structure composed of two different materials, forming a composite elastic belt with soft iron behind and copper in front structure, such as figure 1 shown.

[0020] The welding belt structure proposed by the present invention is suitable for the belt manufacturing process of shells with a diameter of 30-100 mm. The welding method selected is hot wire TIG, that is, tungsten argon arc welding and arc hot wire semi-automatic feeding. Welding of elastic belts, such as figure 2 shown. Connect the two electrodes of the secondary TIG power supply to the wire feed nozzle and the workpiece respectively to form a conductive loop. At the beginning of the welding process, connect the main welding circuit, ignite the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com