Condensing system for window-type air conditioners

A technology for condensing systems and air conditioners, applied in air conditioning systems, evaporators/condensers, refrigerators, etc., can solve the problems of low heat exchange efficiency of condensers, and achieve the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

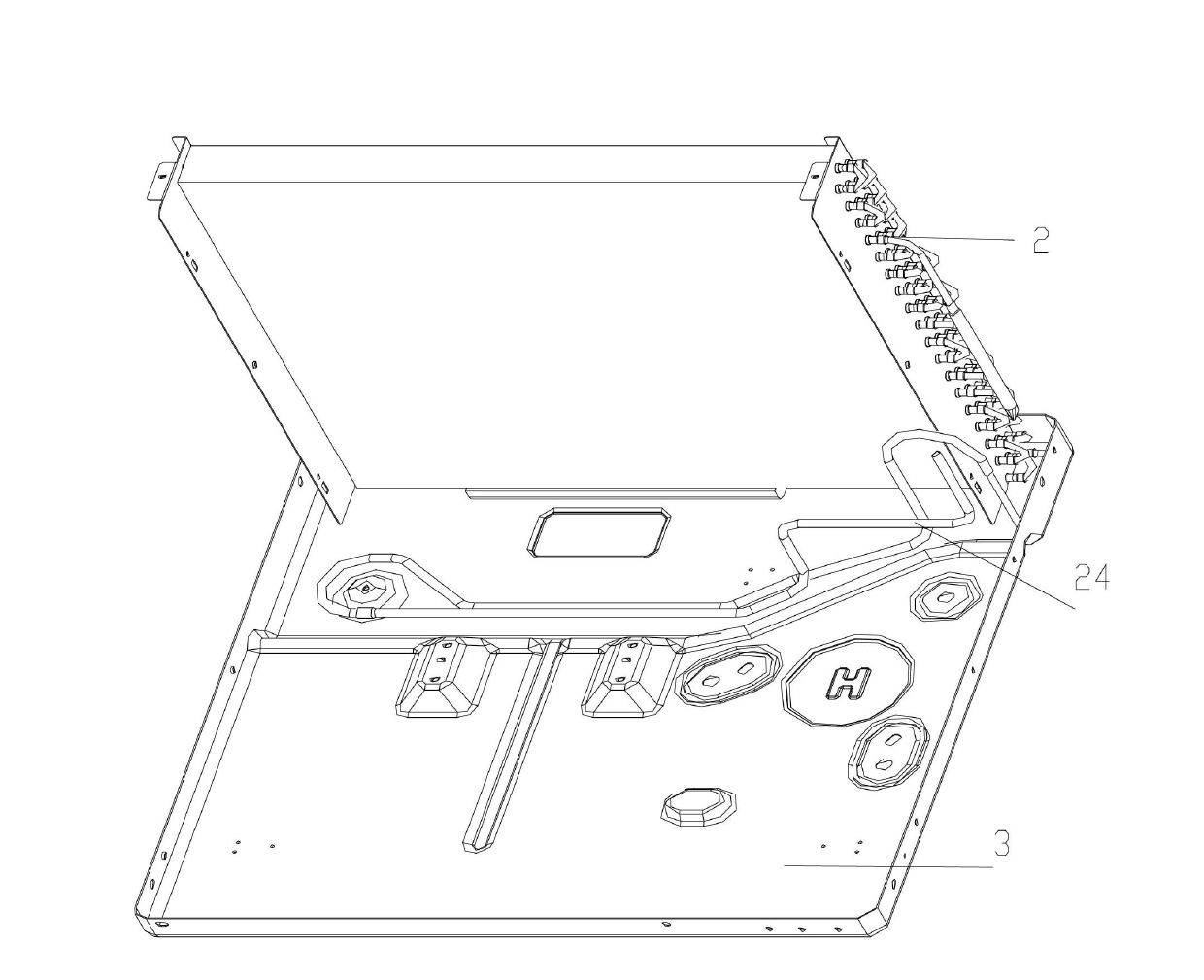

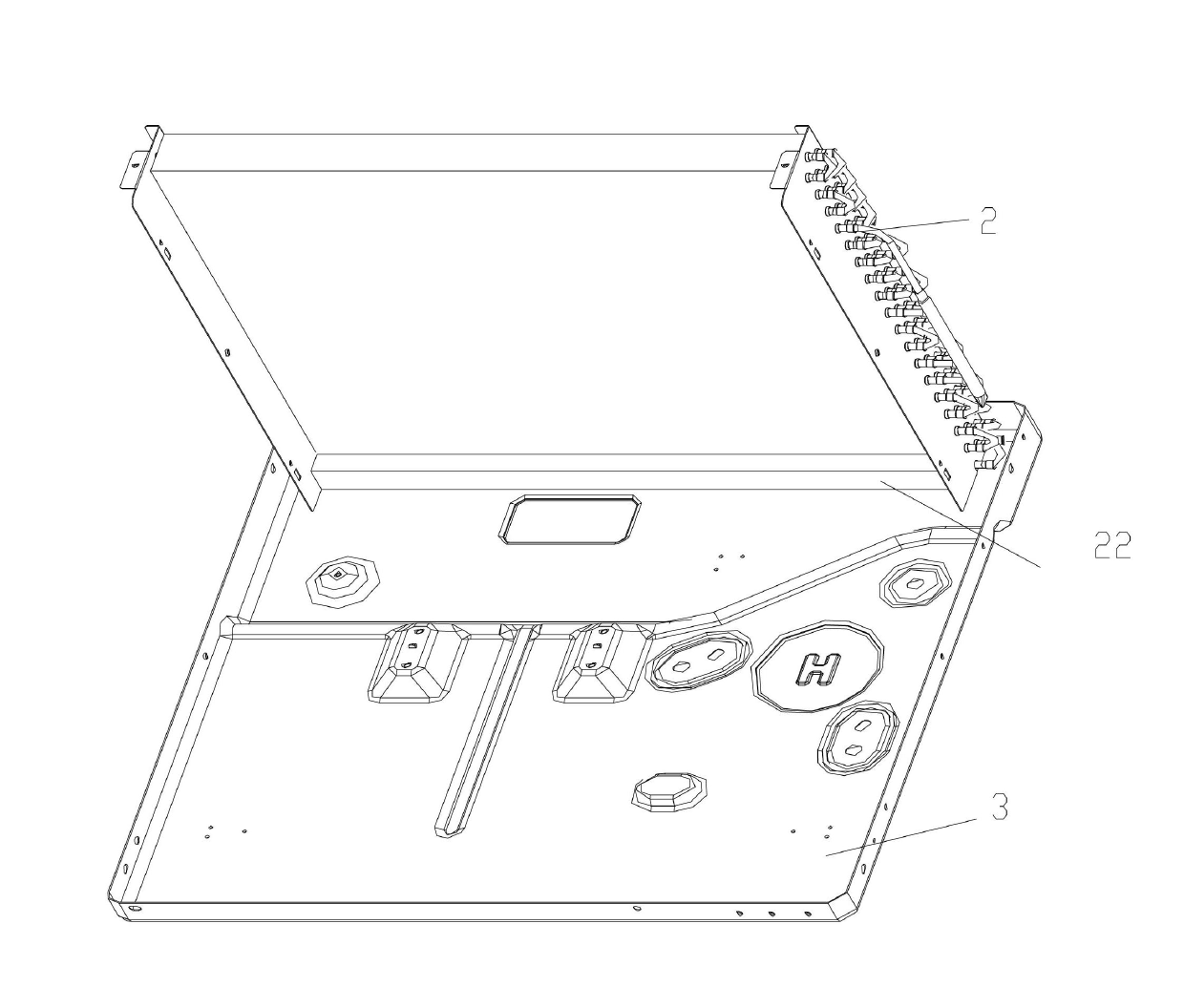

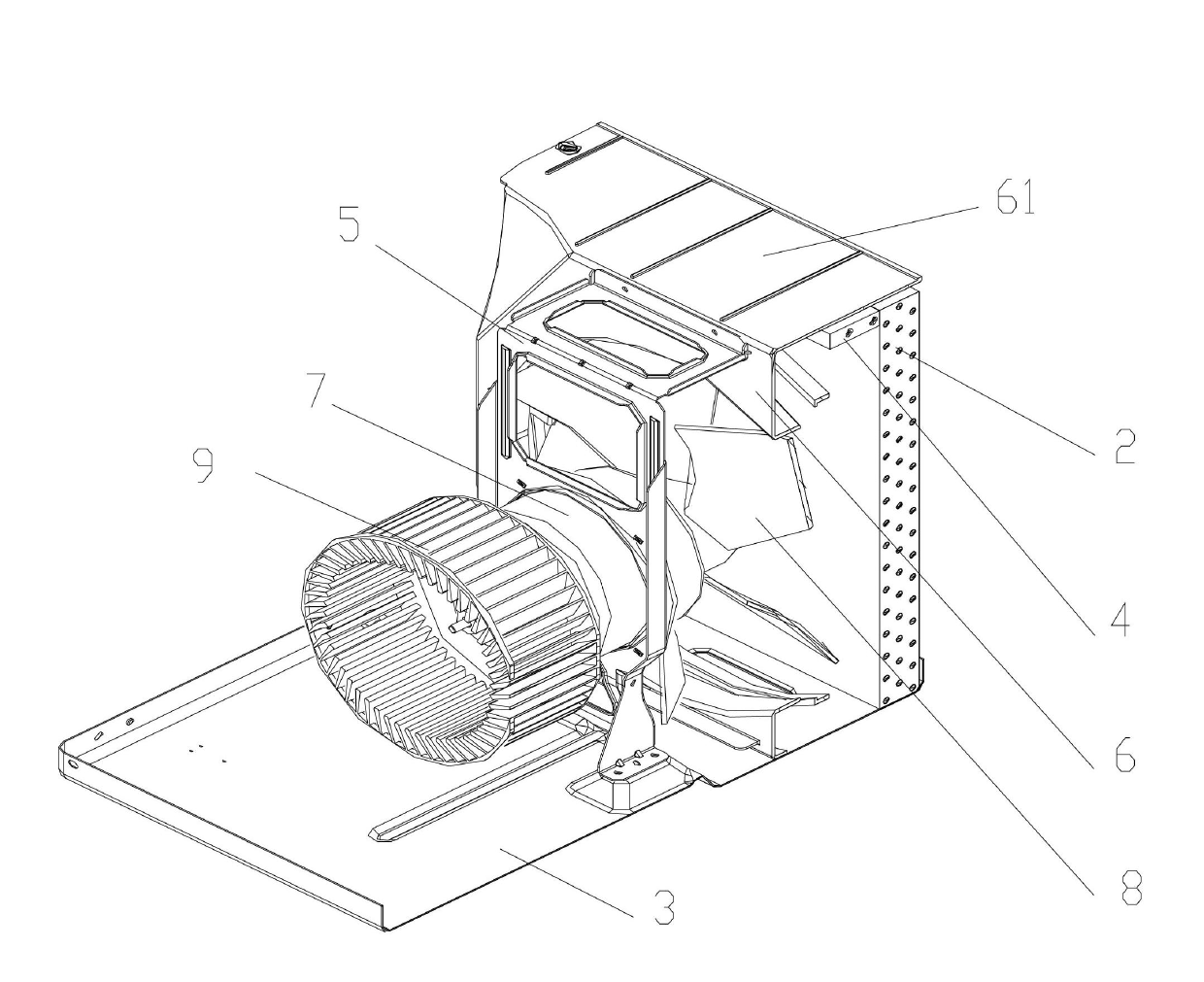

[0024] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0025] see Figure 3-5 , the condensing system of the window air conditioner of the present invention comprises: axial flow fan 8, condenser 2, cooler 4, compressor 13, wherein the exhaust port of compressor 13, the inlet end of cooler 4, the outlet of cooler 4 end, and the refrigerant inlet of the condenser 2 are sequentially connected to form a refrigerant passage.

[0026] The cooler has a cooling coil, and the inlet and outlet of the cooling coil constitute the inlet and outlet ports of the cooler respectively, so that the cooler 4 can be blown by the axial fan 8 and the condensed water thrown off by the axial fan 8 Cooling together, the position of the cooler 4 is set to: be fixed on the side of the top plate 61 facing the axial flow fan 8 in the rear partition, and be located above the axial flow fan 8, and on the inside of the condenser 2 (the win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com