Concrete hollow slab bridge reinforced by transverse steel beams

A hollow slab bridge and concrete technology, used in bridges, bridge parts, bridge construction and other directions, can solve the problems of bridge lateral force transmission performance decline, high requirements for equipment and hinged concrete defects, etc., to achieve easy construction quality assurance, overall High structural strength and obvious reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

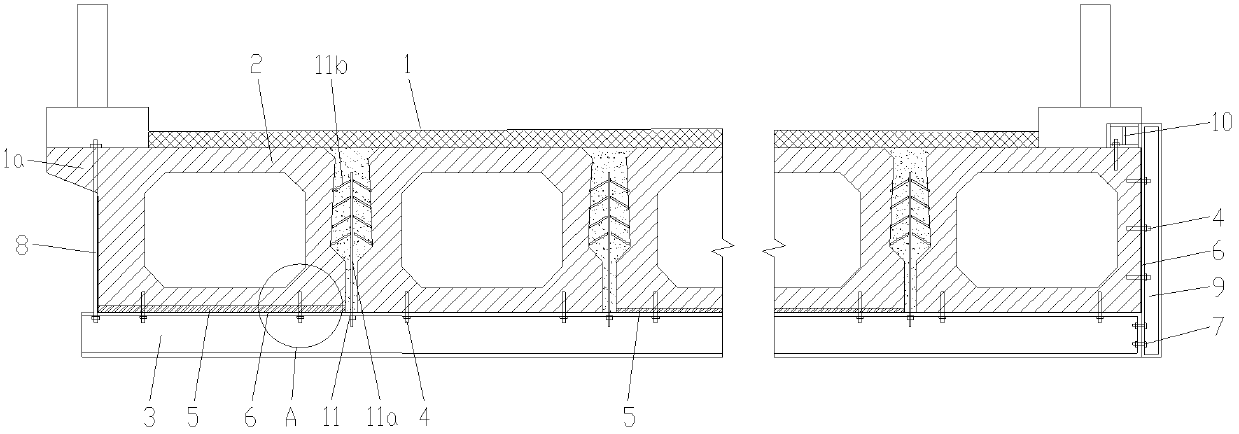

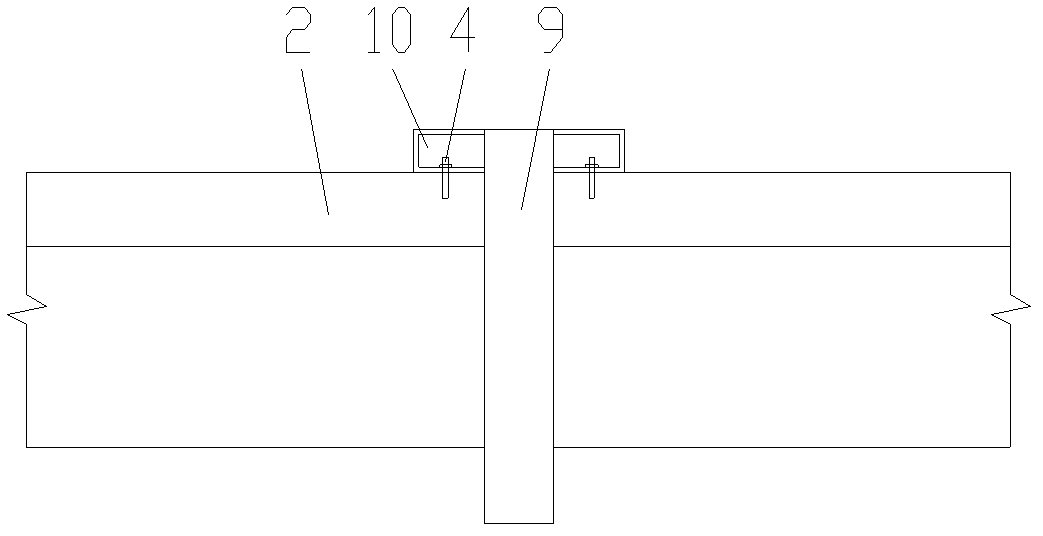

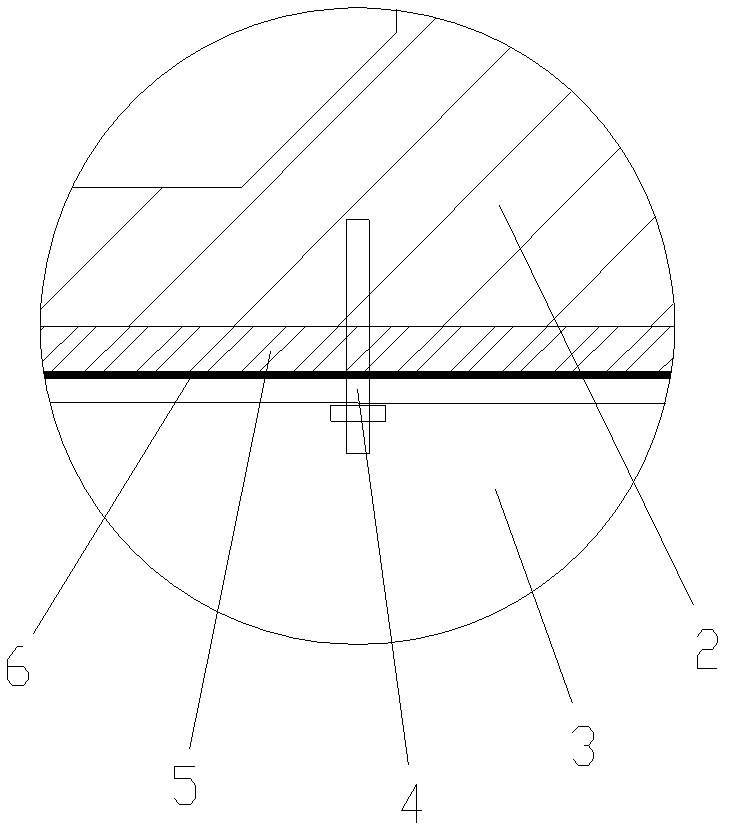

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 right view of the image 3 for figure 1 The enlarged view at A in the middle is shown in the figure: the concrete hollow slab bridge reinforced with transverse steel girders in this embodiment includes a bridge deck beam 1 formed by a plurality of hollow slab girders 2 arranged side by side and a bridge deck beam 1 arranged on the bridge deck. At least one stiffening beam 3 on the bottom surface of the beam 1 is used to laterally reinforce it so that the load on each hollow slab girder 2 can be transmitted laterally. For hollow slab bridges, it is enough to install one stiffening beam 3 in the middle of the span. For hollow bridges with serious hinge joint disease, three or more stiffening beams 3 can be installed according to the overall stress requirements, which can improve the bearing capacity of the bridge and avoid single-slab stress and prolong the service life of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com