Electromagnetic shielding material with chemically plated iron modified carbon nano-tubes and method for preparing same

A technology of electromagnetic shielding materials and multi-walled carbon nanotubes, applied in liquid chemical plating, magnetic field/electric field shielding, nanotechnology for materials and surface science, etc., can solve expensive and complex problems, and achieve comprehensive application performance Improving and improving the effect of magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

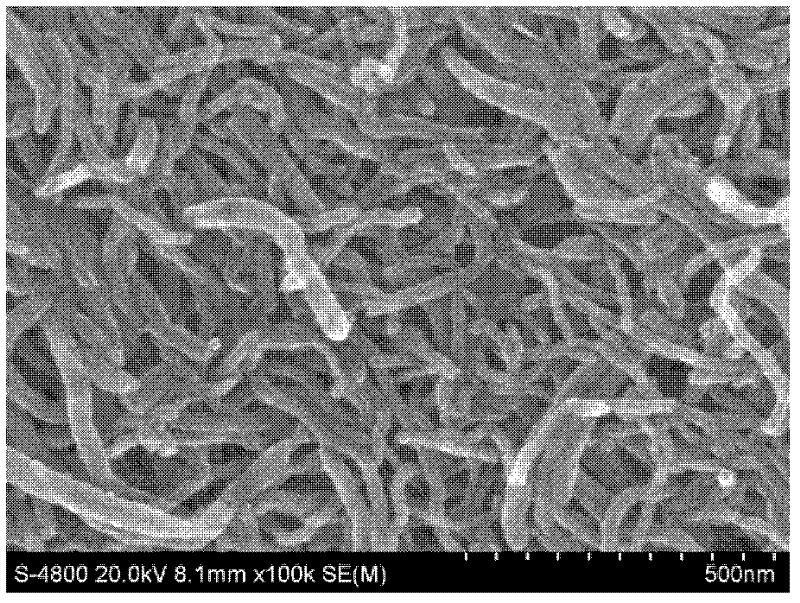

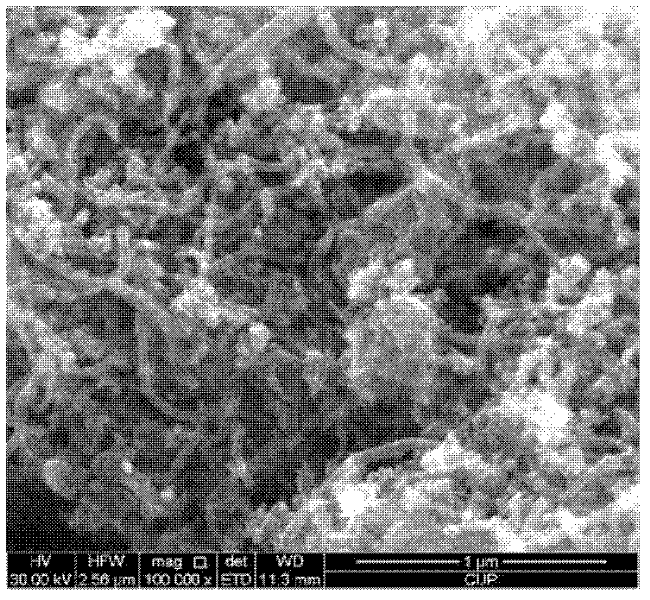

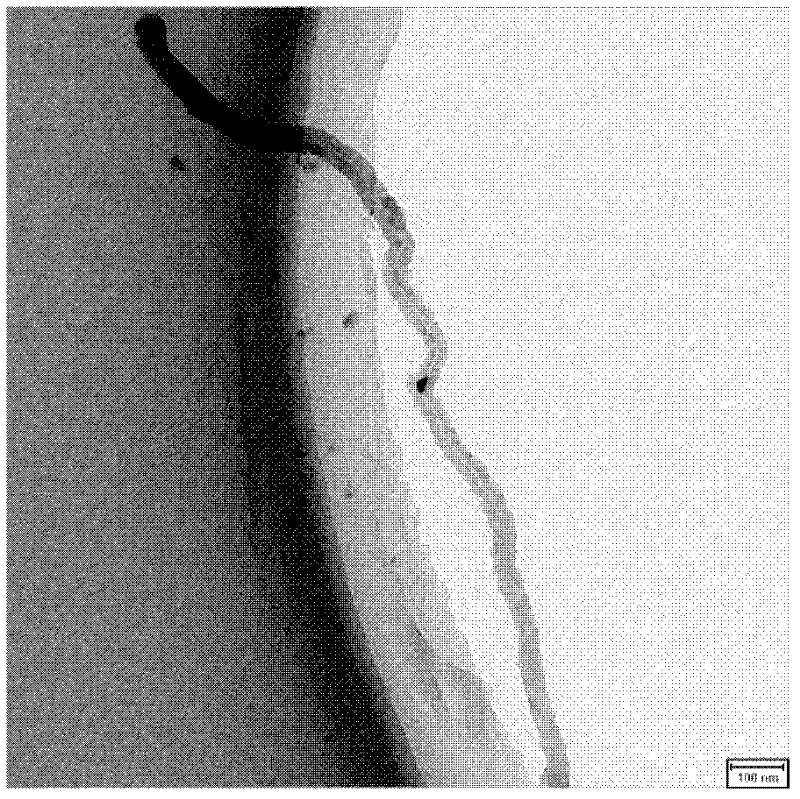

Image

Examples

Embodiment 1

[0032] Take the modification of 0.9g multi-walled carbon nanotubes as an example below to further illustrate the preparation method of the electromagnetic shielding material of electroless iron-plating modified carbon nanotubes provided by the present invention. The specific steps are as follows:

[0033] Step 1, acidification pretreatment of multi-walled carbon nanotubes:

[0034] 1. Mix 67.5ml of concentrated sulfuric acid and 22.5ml of concentrated nitric acid at a volume ratio of 3:1, add 0.9g of multi-walled carbon nanotubes at 60-65°C, ultrasonically stir and reflux for 4 hours; then mix the concentrated sulfuric acid containing multi-walled carbon nanotubes Slowly add the mixed solution of concentrated nitric acid into deionized water, vacuum filter, and repeatedly wash the multi-walled carbon nanotubes obtained after vacuum filtration with deionized water until the washing solution is neutral.

[0035] The vacuum degree in the vacuum suction filtration is -0.03MPa~-0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com