Thermal treatment method for hinge pin shaft of hydraulic support

A heat treatment method and hydraulic support technology, applied in the field of heat treatment, can solve problems such as brittle fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

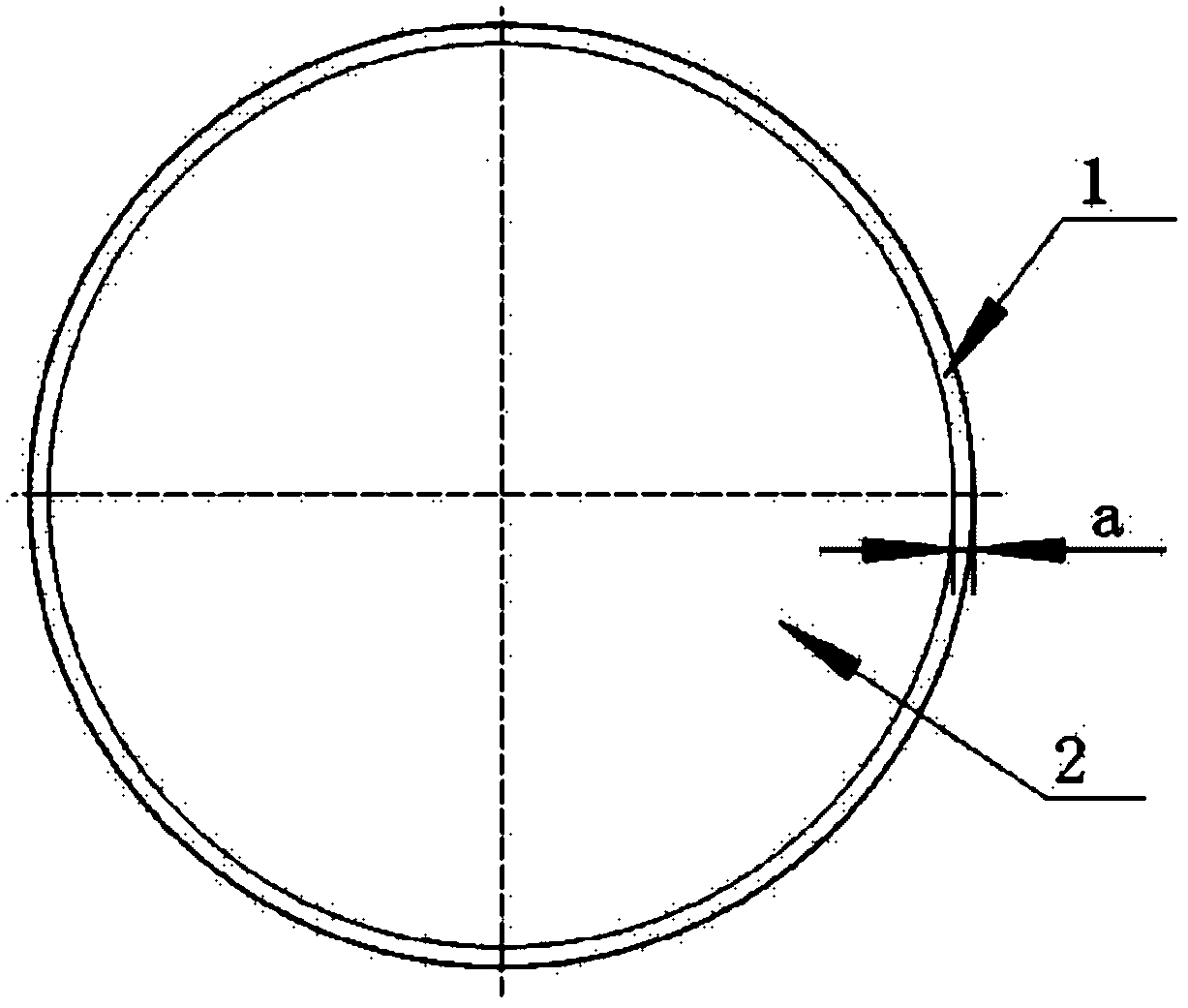

[0022] Tempered hardness HB240~HB300, surface hardness HRC44~HRC48.

[0023] Medium-frequency induction heating: the current frequency is 500-10000Hz (Hertz), and the effective hardening depth is 2-10mm (millimeters). Effect, the induced current accumulates on the surface of the material to generate heat, reaches the phase transition temperature, and quenches to achieve the purpose of quenching. It not only changes its structure and performance, but also improves the surface hardness and wear resistance of parts. With the pre-heat-treated heart tissue, higher fatigue strength and toughness are obtained.

[0024] The applicant found that the austenitization of steel is carried out at a relatively high degree of superheat (80-150°C above Ac3), and there are many crystal nuclei, which are not easy to grow. After quenching, the structure is fine cryptocrystalline martensite, and the brittleness is low; After the surface layer is quenched to obtain martensite, the volume expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com