Multistable display material and preparation method

A multi-stable, display agent technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of small operating temperature range, insufficient response speed, unstable cholesteric liquid crystal pitch, etc., and achieve low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

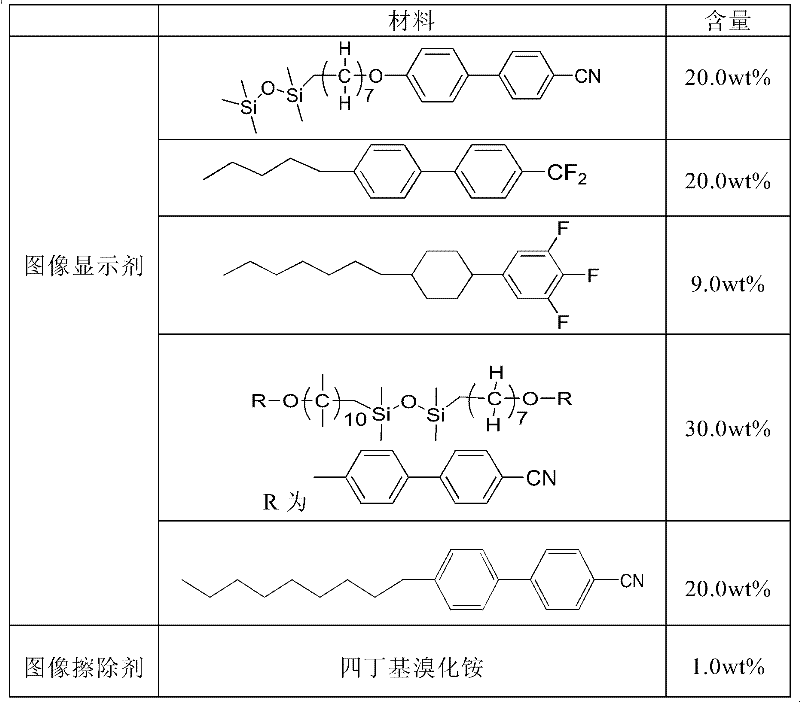

Embodiment 1

[0027] The image display agent and image eraser listed in Table 1 were weighed and mixed in proportion, put into a quartz glass container, heated to 40° C., ultrasonically oscillated for 30 minutes, and cooled to room temperature. The obtained mixture is the multi-stable display material of this embodiment. Weigh 0.01 g of the multi-stable display material and pour it into a glass hollow box whose inner surface is coated with a simple image made of ITO material through capillary action. Place the prepared glass box in a temperature-adjustable heating stage, and use an AC signal output device capable of adjusting voltage (3V-100V), frequency (5HZ-10KHZ) and waveform number (the waveform used is a square wave) to pair A series of tests are performed by applying electrical signals to a glass cell in a hot stage. The measured operating temperature is -10°C to 60°C, the best driving voltage is 35V, the image erasing time is 2 milliseconds, and the image display time is 5 millisecon...

Embodiment 2

[0031] The image display agent and image eraser listed in Table 2 were weighed and mixed in proportion, put into a quartz glass container, heated to 150° C., ultrasonically oscillated for 1 min, and cooled to room temperature. The obtained mixture is the multi-stable display material of this embodiment. Weigh 0.01 g of the multi-stable display material and pour it into a glass hollow box whose inner surface is coated with a simple image made of ITO material through capillary action. Place the prepared glass box in a temperature-adjustable heating stage, and use an AC signal output device capable of adjusting voltage (3V-100V), frequency (5HZ-10KHZ) and waveform number (the waveform used is a square wave) to pair A series of tests are performed by applying electrical signals to a glass cell in a hot stage. The measured operating temperature is -20°C to 50°C, the best driving voltage is 20V, the image erasing time is 5 milliseconds, and the image display time is 7 milliseconds. ...

Embodiment 3

[0035]The image display agent and image eraser listed in Table 3 were weighed and mixed in proportion, put into a quartz glass container, heated to 80° C., ultrasonically oscillated for 50 minutes, and cooled to room temperature. The obtained mixture is the multi-stable display material of this embodiment. Weigh 0.01 g of the multi-stable display material and pour it into a glass hollow box whose inner surface is coated with a simple image made of ITO material through capillary action. Place the prepared glass box in a temperature-adjustable heating stage, and use an AC signal output device capable of adjusting voltage (3V-100V), frequency (5HZ-10KHZ) and waveform number (the waveform used is a square wave) to pair A series of tests are performed by applying electrical signals to a glass cell in a hot stage. The measured operating temperature is 0°C to 75°C, the optimum driving voltage is 70V, the image erasing time is 2 milliseconds, and the image displaying time is 8 millise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com