Preparation method of carbon nano tube composite material with high-content uniformly dispersed carbon nano tubes

A carbon nanotube and composite material technology, which is applied to the preparation field of carbon nanotube composite materials, can solve the problems of uneven dispersion, disorderly arrangement, low volume content of carbon tubes, etc., and achieves broad application prospects, simple process and controllable production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of carbon nanotubes / polyvinyl alcohol composites with uniform dispersion of carbon nanotubes:

[0034] (1) Selecting a diameter of 20 nanometers and multi-walled carbon nanotubes with a length of 50-100 microns as the carbon nanotube material, the carbon nanotube material is added to the volatile solvent alcohol, and the dispersant sodium dodecylsulfonate is added (SDS), wherein, the ratio of carbon nanotubes, volatile solvent and dispersant is 1mg: 2mL: 0.5mg; under the condition of ultrasonic oscillation with a frequency of 53KHz, the oscillation time is 4 hours, and the carbon nanotubes in the volatile solvent evenly dispersed.

[0035] (2) 1 g of polymer PVA was dissolved in 1 L of ethanol solution with a concentration of 90 vol % to prepare a polymer solution.

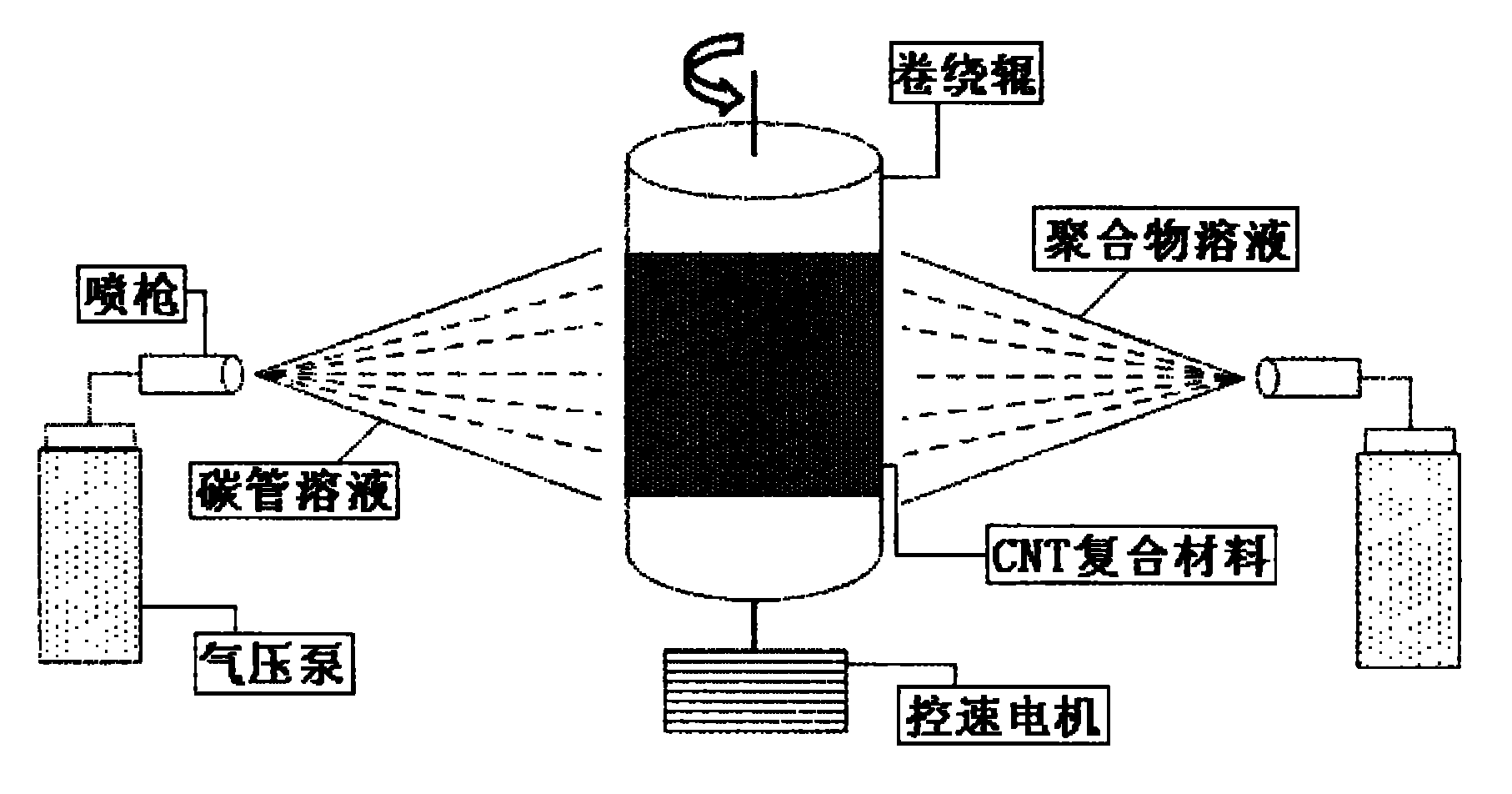

[0036] (3) if Figure 1a with Figure 1b As shown, the winding roller made of polytetrafluoroethylene is connected to the speed control motor, a layer of polyester film is laid on the winding ...

Embodiment 2

[0039] Preparation of carbon nanotube composites with carbon nanotubes and polymer uniformly mixed layer and polymer layer spaced in the horizontal direction:

[0040] (1) choose diameter to be 20 nanometers, the multi-walled carbon nanotube of length 50-100 micron is carbon nanotube material, carbon nanotube material is joined in the volatile solvent alcohol solution, adds dispersant dodecyl sulfonic acid Sodium (SDS), wherein the ratio of carbon nanotubes, volatile solvent and dispersant is 1mg: 2mL: 0.5mg; oscillating for 4 hours under the condition of ultrasonic oscillation with a frequency of 53KHz, to realize the uniformity of carbon nanotubes in the volatile solvent dispersion.

[0041] (2) 1 g of polymer PVA was dissolved in 1 L of ethanol solution with a concentration of 90 vol % to prepare a polymer solution.

[0042] (3) if Figure 2a As shown, the winding roller made of polytetrafluoroethylene is connected to the speed control motor, a layer of polyester film is ...

Embodiment 3

[0045] Preparation of carbon nanotube composites in which carbon nanotubes and polymers are uniformly mixed and distributed in the thickness direction:

[0046] (1) Select the multi-walled carbon nanotubes with a diameter of 20 nanometers and a length of 50-100 microns as the carbon nanotube material, add the carbon nanotube material to the volatile solvent alcohol solution, and add the dispersant SDS, wherein the carbon nanotube The ratio of the tube, the volatile solvent and the dispersant is 1mg: 2mL: 0.5mg; under the condition of ultrasonic oscillation with a frequency of 53KHz, the oscillation time is 4 hours to realize the uniform dispersion of the carbon nanotubes in the volatile solvent.

[0047] (2) 1 g of polymer PVA was dissolved in 1 L of ethanol solution with a concentration of 90 vol % to prepare a polymer solution.

[0048] (3) if Figure 1a and Figure 1b As shown, the winding roller made of polytetrafluoroethylene is connected to the speed control motor, a la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com