Portable plastic repairing machine

A portable and plastic technology, applied in the field of portable plastic repair machines, can solve the problems of increased production cost, large wire loss, inconvenience to carry, etc., and achieves the effect of reducing power loss, reducing production cost, and being easy to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

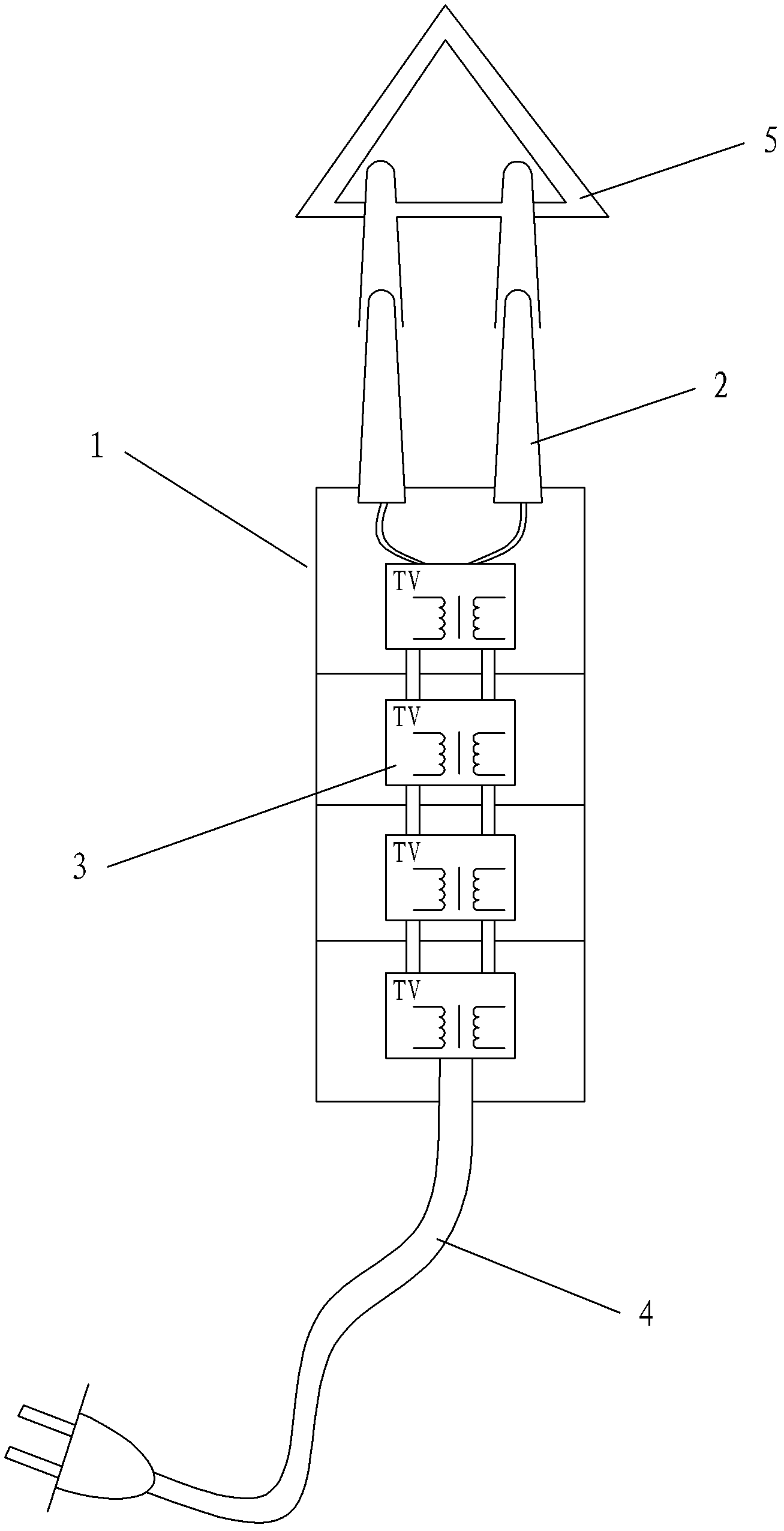

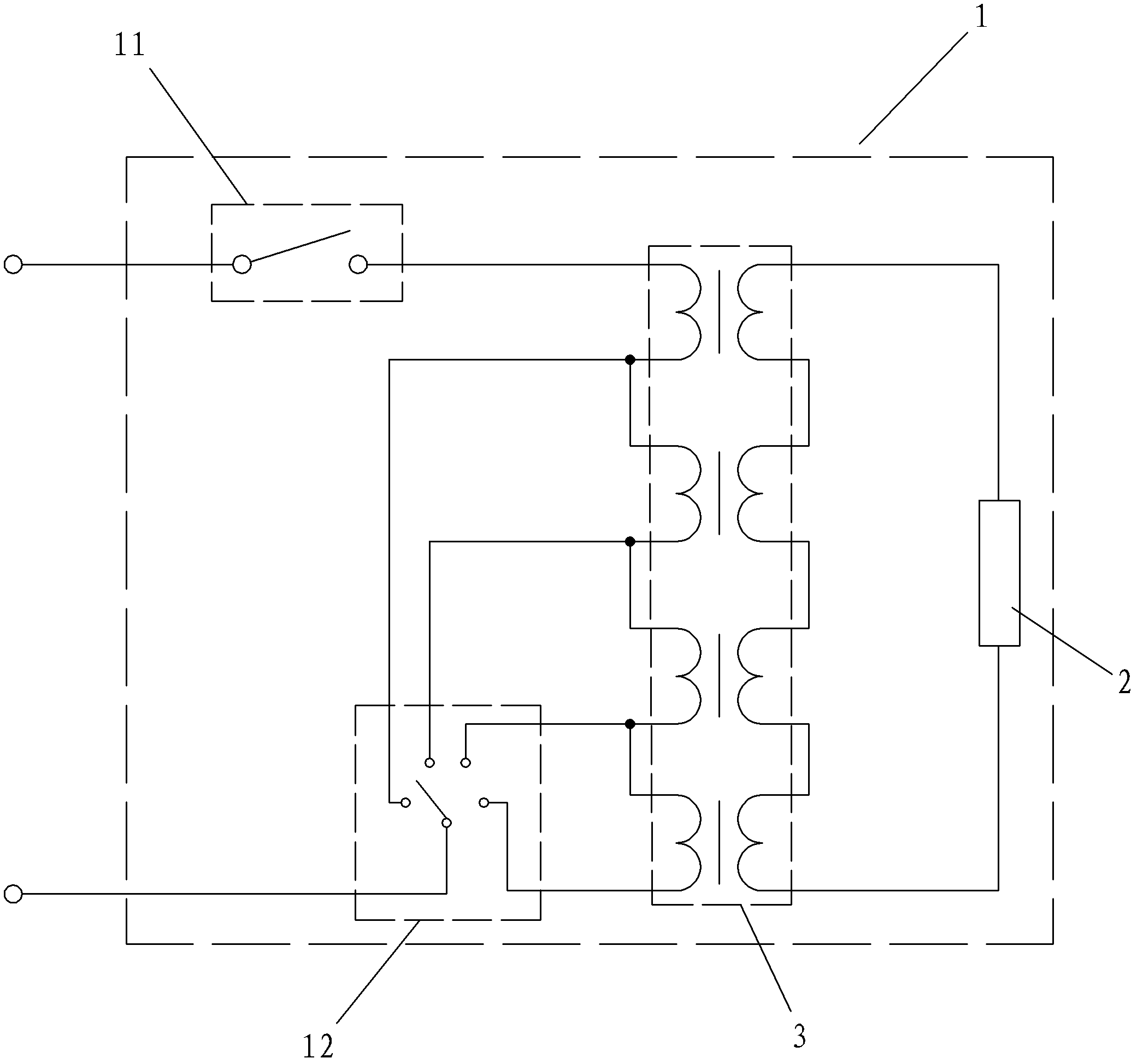

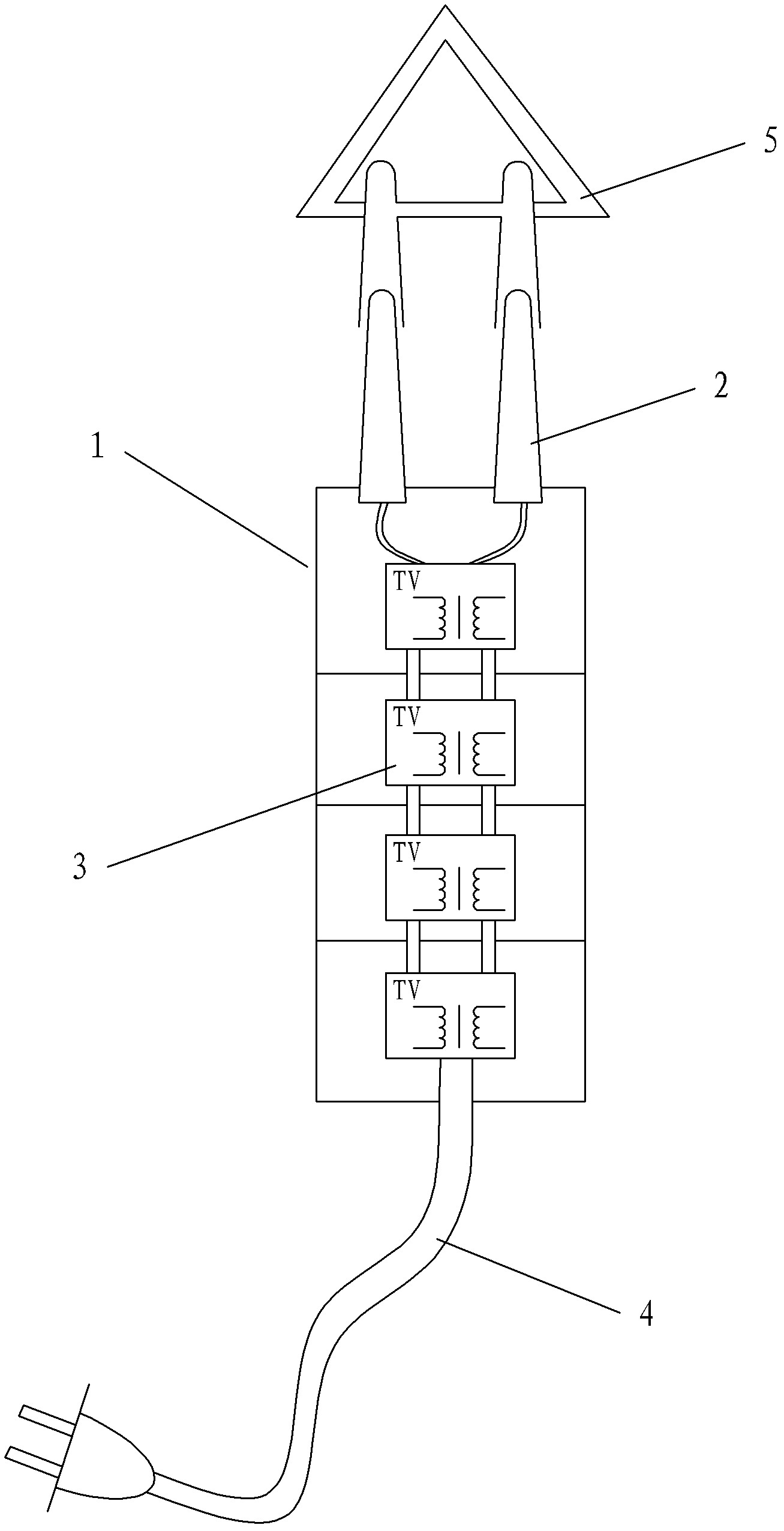

[0017] refer to figure 1 , figure 2 , an embodiment of a portable plastic repair machine provided by the present invention, including an operating handle 1, the front end of the operating handle 1 is provided with a welding head 2 for energizing and heating, and a transformer group 3 is arranged inside the operating handle 1, and the transformer group 3 can be It is composed of two or more transformers connected in series, and can also be composed of two or more transformers connected in parallel. In this embodiment, the transformer group 3 is preferably composed of four transformers connected in series, and the output terminal of the transformer group 3 is connected to the The welding head 2 is connected, the input end of the transformer group 3 is connected to an external power supply through the lead wire 4, and the control switch 11 for controlling the input power supply of the transformer group 3 and the control switch 11 for adjusting the output voltage and current conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com