Moving roller-type circular mould granulator

A granulator and ring die technology, applied in the direction of mold extrusion granulation, etc., can solve the problem of non-stop adjustment of the gap between the ring die and the pressure roller, etc., to achieve convenient and quick adjustment, reduce operation difficulty, and ensure production safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

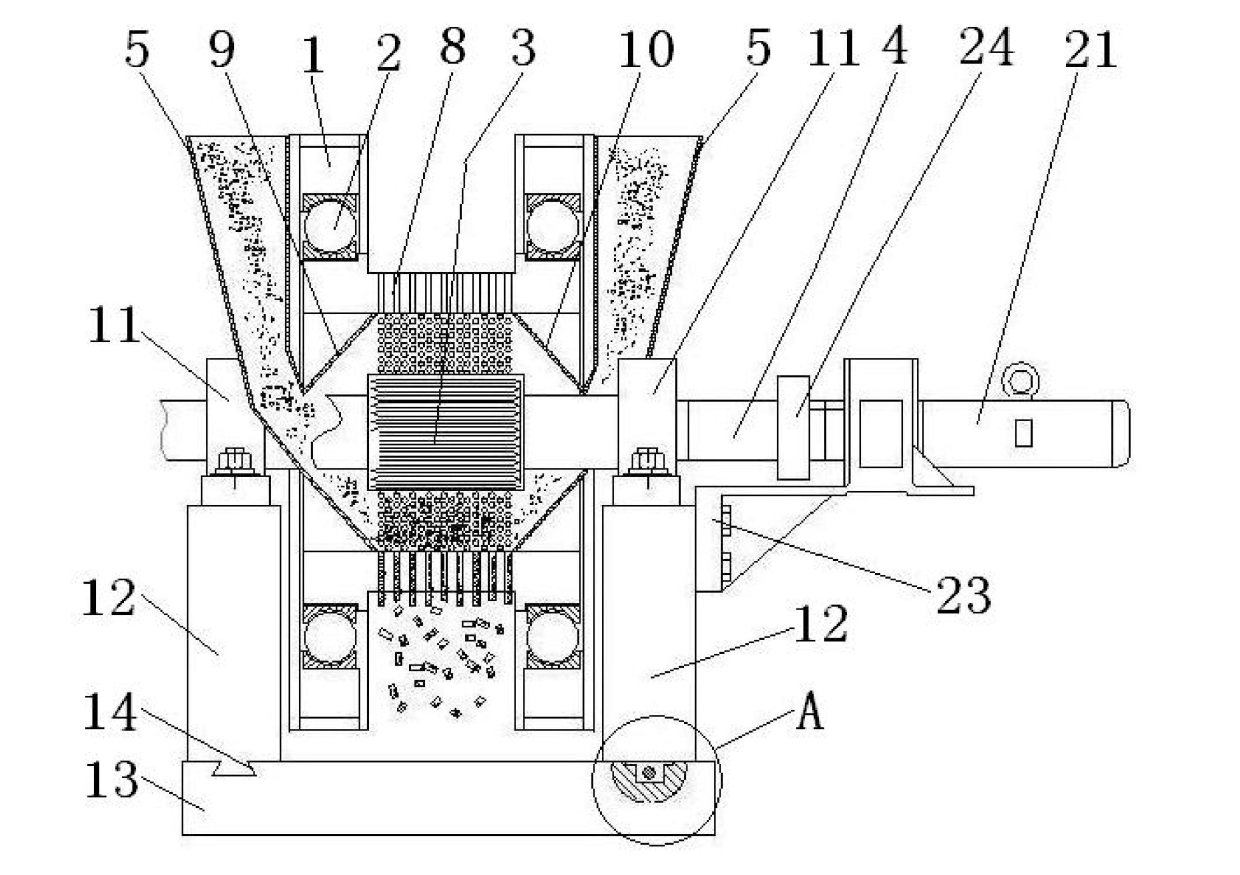

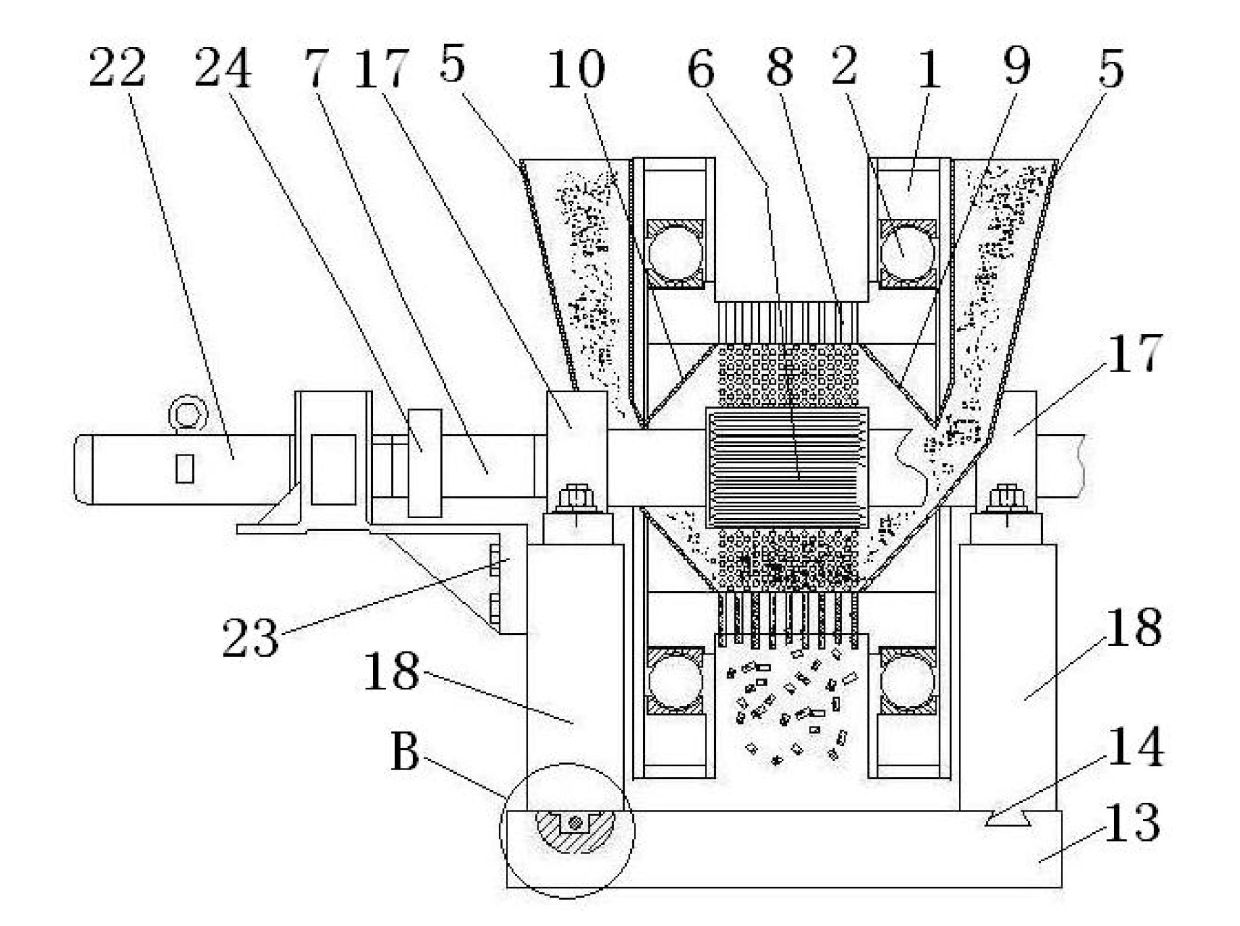

[0029] figure 1 It is a schematic diagram of an embodiment of a moving-roller ring die granulator. The moving-roller ring die granulator mainly includes a ring die 8 and a pair of parallel left press rollers 3 and right press rollers 6 arranged horizontally in the ring die 8. , the gaps between the left pressure roller 3 and the right pressure roller 6 and the inner surface of the ring die 8 are not greater than 2 mm. The ring die bearing seat 1 is vertically fixed on the base 13. The ring die bearing seat 1 is fixed inside, and the inner circle of the ring die 8 and the ring die bearing 2 is fixedly connected to form a rotational connection between the ring die 8 and the ring die bearing seat 1 . When the material enters the gap between the ring die 8 and the pressure roller, the ring die 8 also rotates clockwise under the action of fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com