Gas sensitive element taking houghite as precursor and preparation method thereof

A technology of gas sensor and hydrotalcite, which is applied in the field of gas sensor to achieve the effect of simple preparation steps, diversified element composition and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

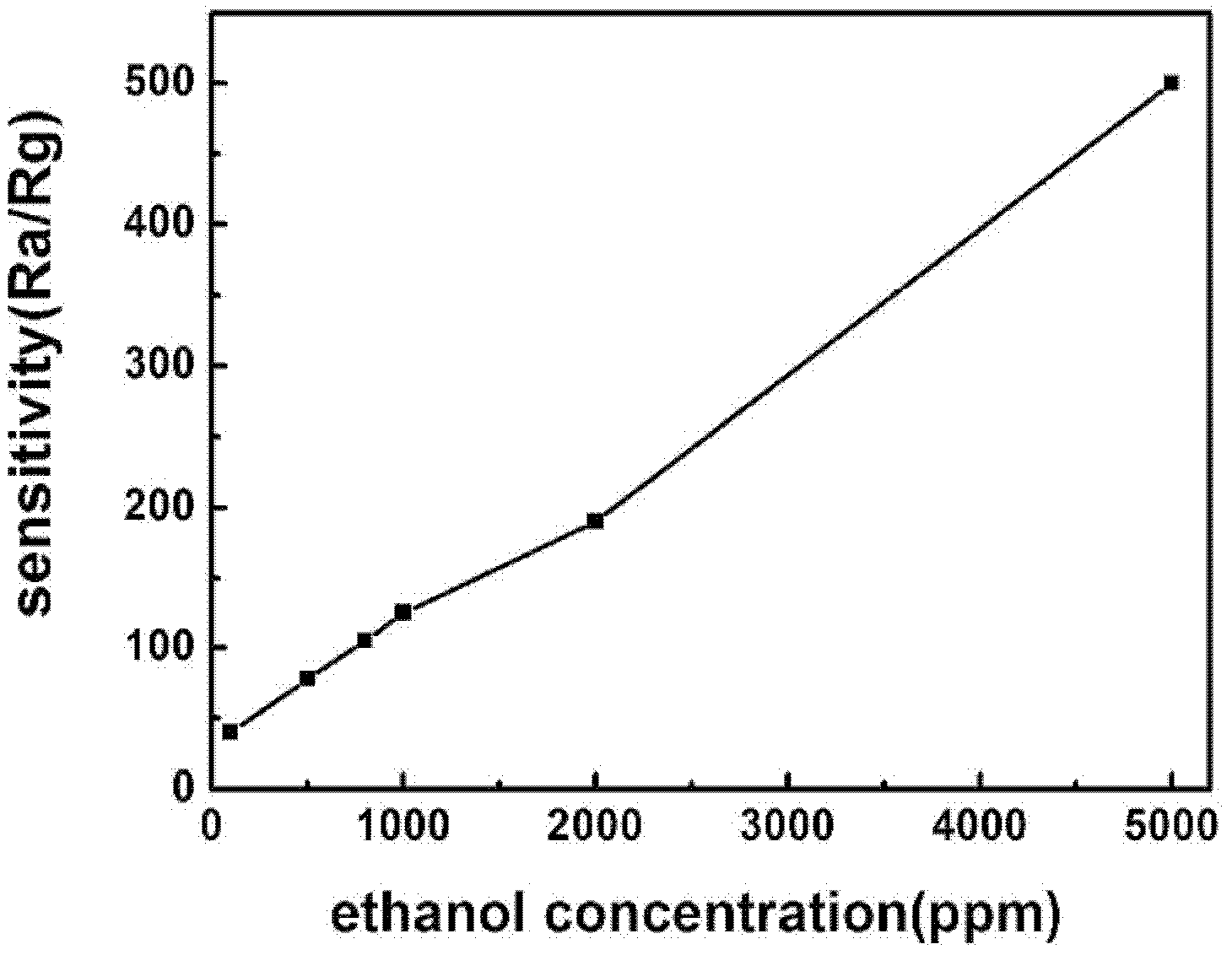

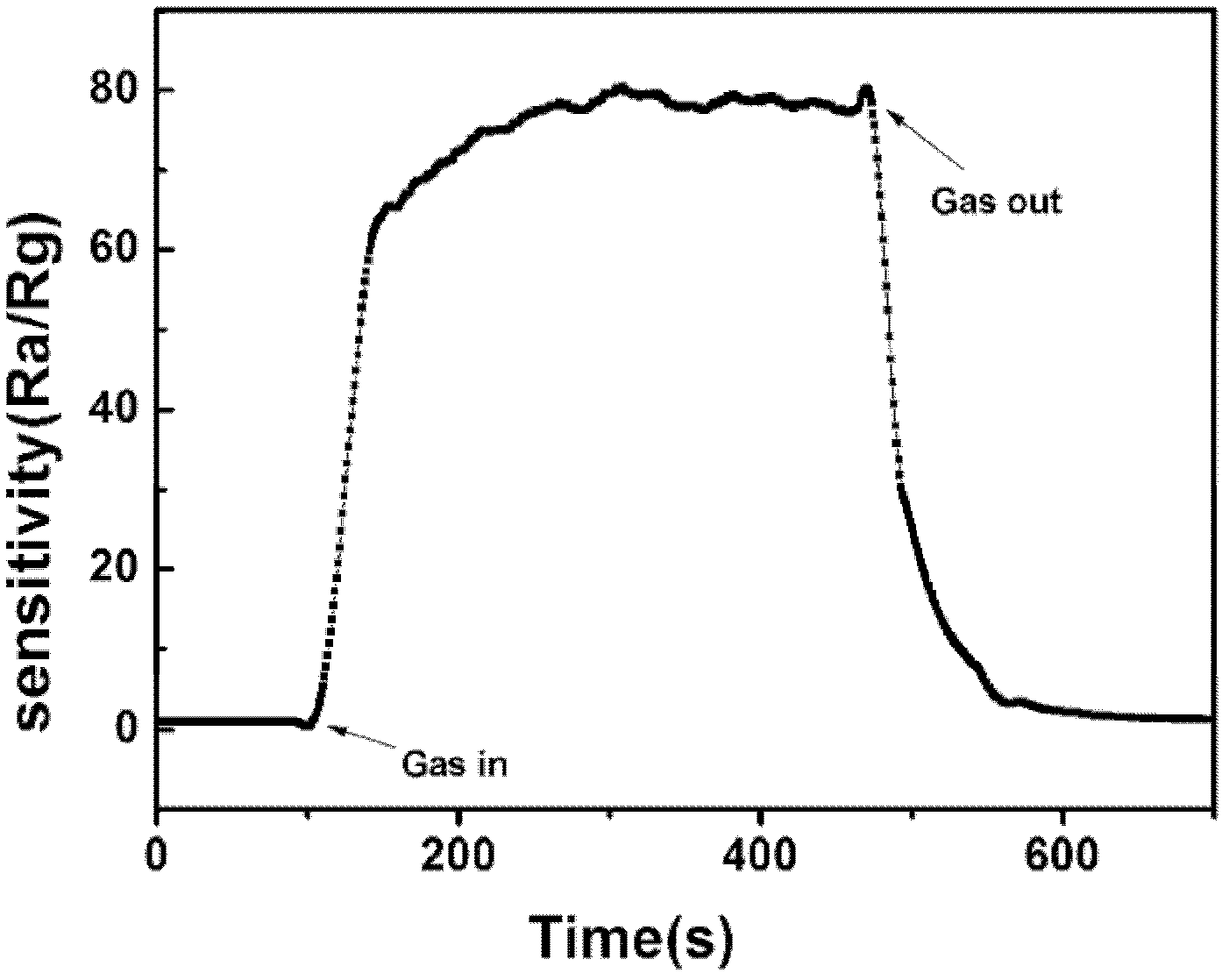

Embodiment 1

[0022] 1. Preparation of hydrotalcite with nitrate between layers by double drop method:

[0023] 0.02mol of solid Zn(NO 3 ) 2 ·6H 2 O and 0.01mol of solid Al(NO 3 ) 3 9H 2 O dissolved in 100ml of deCO 2 Make a mixed salt solution in water, dissolve 0.08mol NaOH in 100ml deCO 2 Make an alkaline solution in deionized water, and then under the protection of nitrogen, drop the two solutions into a four-necked flask at the same time while stirring, control the dropping speed of the alkaline solution, keep the pH of the solution in the flask in the range of 6.5-7, and titrate After completion, continue to stir for 30 minutes, hydrothermal crystallization at 100°C for 12 hours, and use CO removal 2 Centrifuge and wash with water until neutral, and dry at 60°C for 24 hours to obtain nitrate intercalated hydrotalcite. The obtained hydrotalcite is calcined at a temperature of 600° C. at a heating rate of 10° C. / min, and kept for 5 hours to form a composite oxide, that is, a sem...

Embodiment 2

[0035] 1. Preparation of hydrotalcite with nitrate between layers by single drop method:

[0036] a, 0.02mol of solid Zn(NO 3 ) 2 ·6H 2 O, 0.01mol of solid Al(NO 3 ) 3 9H 2 O and 0.001 mol of solid La(NO 3 ) 3 · 4H2O dissolved in 100ml of deCO 2 Make a mixed salt solution in water, dissolve it evenly and transfer it to a four-neck flask, dissolve 0.08mol of NaOH in 100ml of CO 2 The solution prepared in ionized water was transferred to the constant pressure dripping funnel, and then under the protection of nitrogen, the lye was slowly dropped into the flask while stirring, and the pH of the solution was controlled within the range of 5.5-6.5. After the titration was completed, continue to stir for 30 Minutes, hydrothermal crystallization at 100°C for 24 hours, using CO removal 2 Centrifugal washing with ion water until neutral, drying at 60°C for 24 hours to obtain nitrate intercalated hydrotalcite.

[0037] b. Set the obtained hydrotalcite at 1000°C to roast at a he...

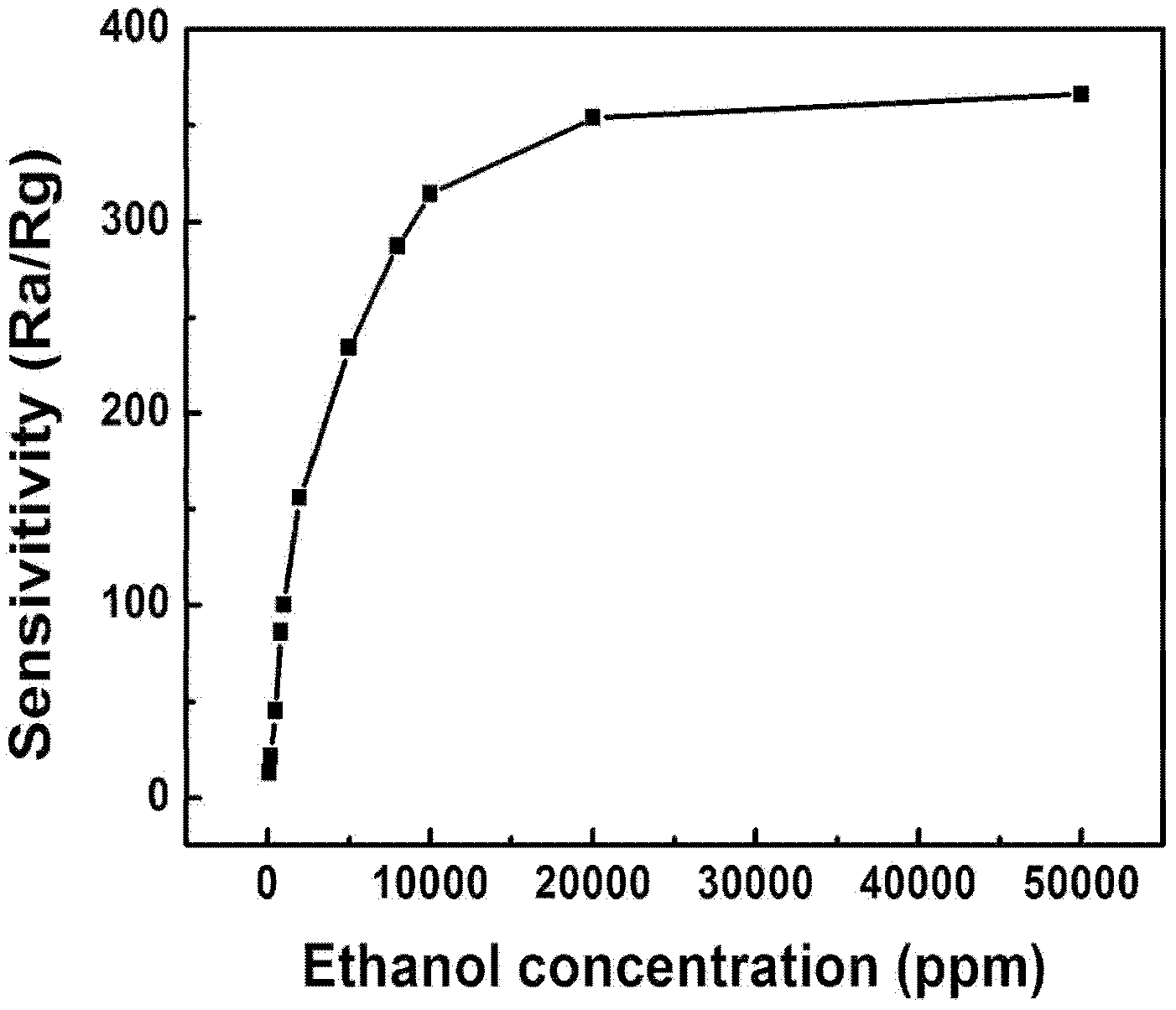

Embodiment 3

[0041] 1. Preparation of hydrotalcite with nitrate between layers by double drop method:

[0042] a, 0.02mol of solid Zn(NO 3 ) 2 ·6H 2 O, 0.01mol of solid Al(NO 3 ) 3 9H 2 O and 0.001mol of solid In(NO 3 ) 3 4H 2 O dissolved in 100ml of deCO 2 Make a mixed salt solution in water, dissolve it evenly and transfer it to a four-neck flask, dissolve 0.08mol of NaOH in 100ml of CO 2 The solution prepared in ionized water was transferred to the constant pressure dripping funnel, and then under the protection of nitrogen, the lye was slowly dropped into the flask while stirring, and the pH of the solution was controlled within the range of 5.5-6.5. After the titration was completed, continue to stir for 30 Minutes, hydrothermal crystallization at 100°C for 24 hours, using CO removal 2 Centrifuge and wash with water until neutral, and dry at 60°C for 24 hours to obtain nitrate intercalated hydrotalcite.

[0043] b. Set the obtained hydrotalcite at 800°C to roast at a heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com