Great-diameter variable section irregularly-shaped resistance-increased steel pipe pile system and construction method thereof

A construction method and technology of steel pipe piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of steel pipe pile bearing capacity difference, small vertical and horizontal bearing capacity, and difficult pile foundation construction, etc. Achieve the effects of fast construction, improved vertical bearing capacity, and easy control of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

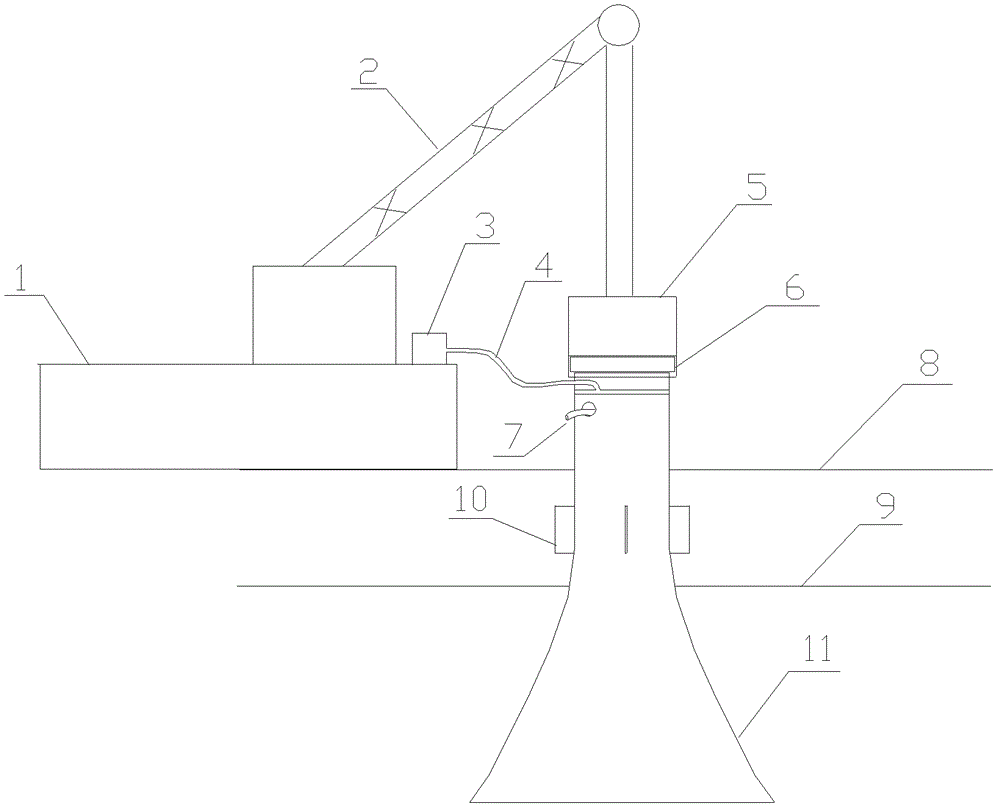

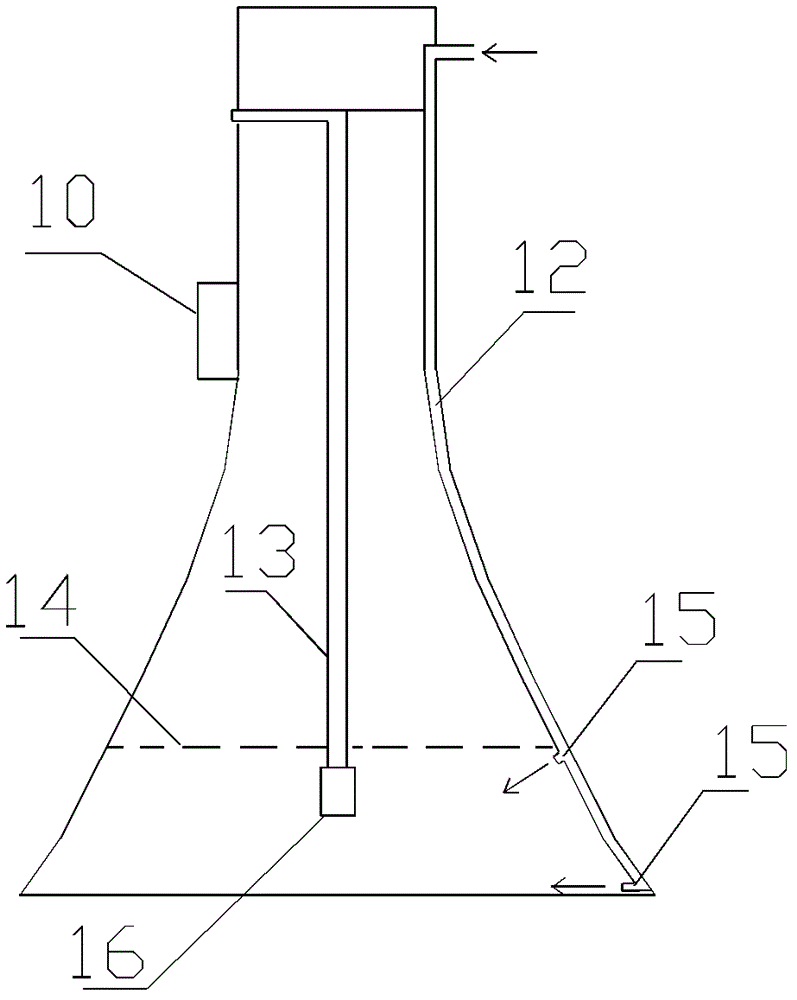

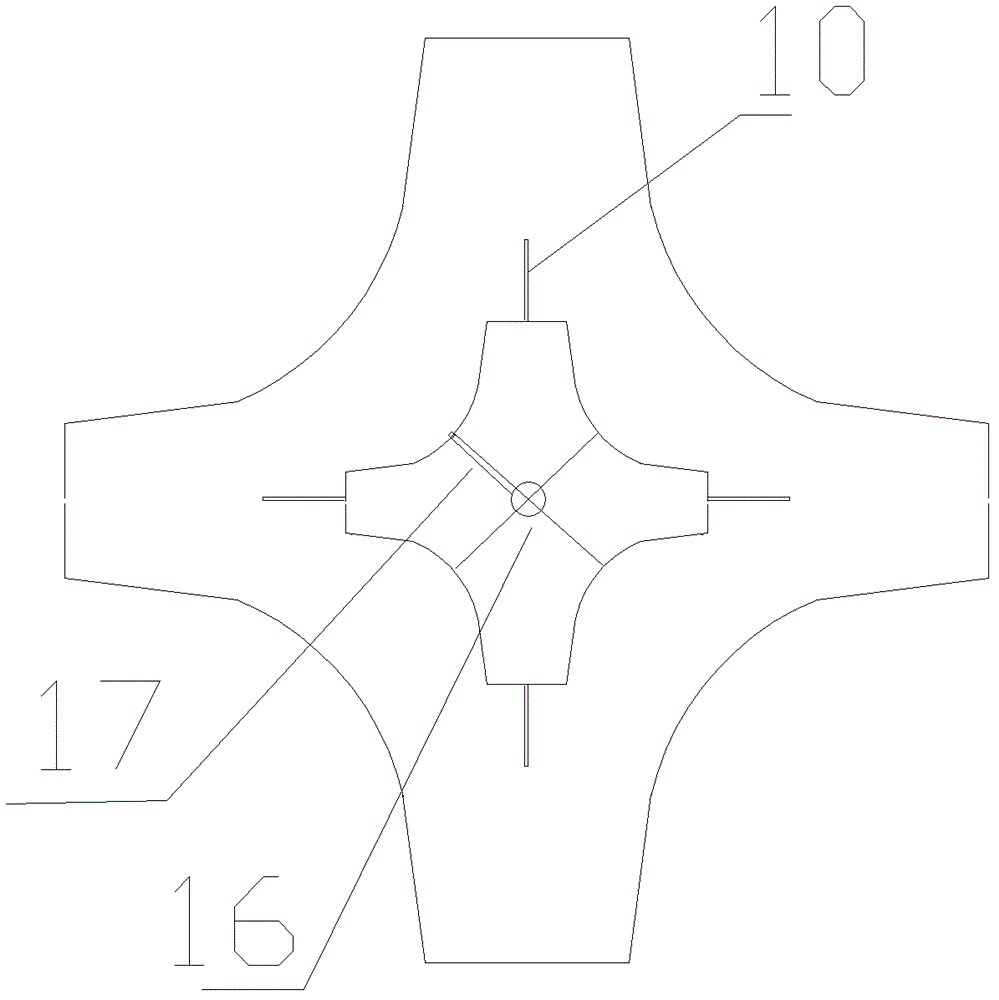

[0041] Such as Figure 1-4 As shown, in view of the convenience of steel plate processing, the cross-section of the pile body of the present invention can adopt various variable cross-sections such as "cross", "triangular", "square" or multi-branch according to the engineering design function requirements of the inner cavity. Take the "cross" pile as an example to illustrate the following:

[0042] It mainly includes the following 17 components, which are described as follows:

[0043] 1. Offshore operation platform 1: provide an operation platform for lifting equipment 2, high-pressure pump 3 and equipment operation.

[0044]2. Lifting device 2: fixedly connected with the offshore operation platform 1, and connected with the vibration hammer 5 through a wire rope. The main function is to lift the steel pipe pile 11 pile body and place and level it a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com