Huperzine A polymorph, its preparation method, medicinal composition containing huperzine A polymorph and its application

A technology of huperzine A and its crystal form, which is applied in the field of preparation of huperzine A polymorph and its synthesis process, and can solve problems not involving the crystal form of huperzine A raw material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1: Preparation of huperzine A crystal form I.

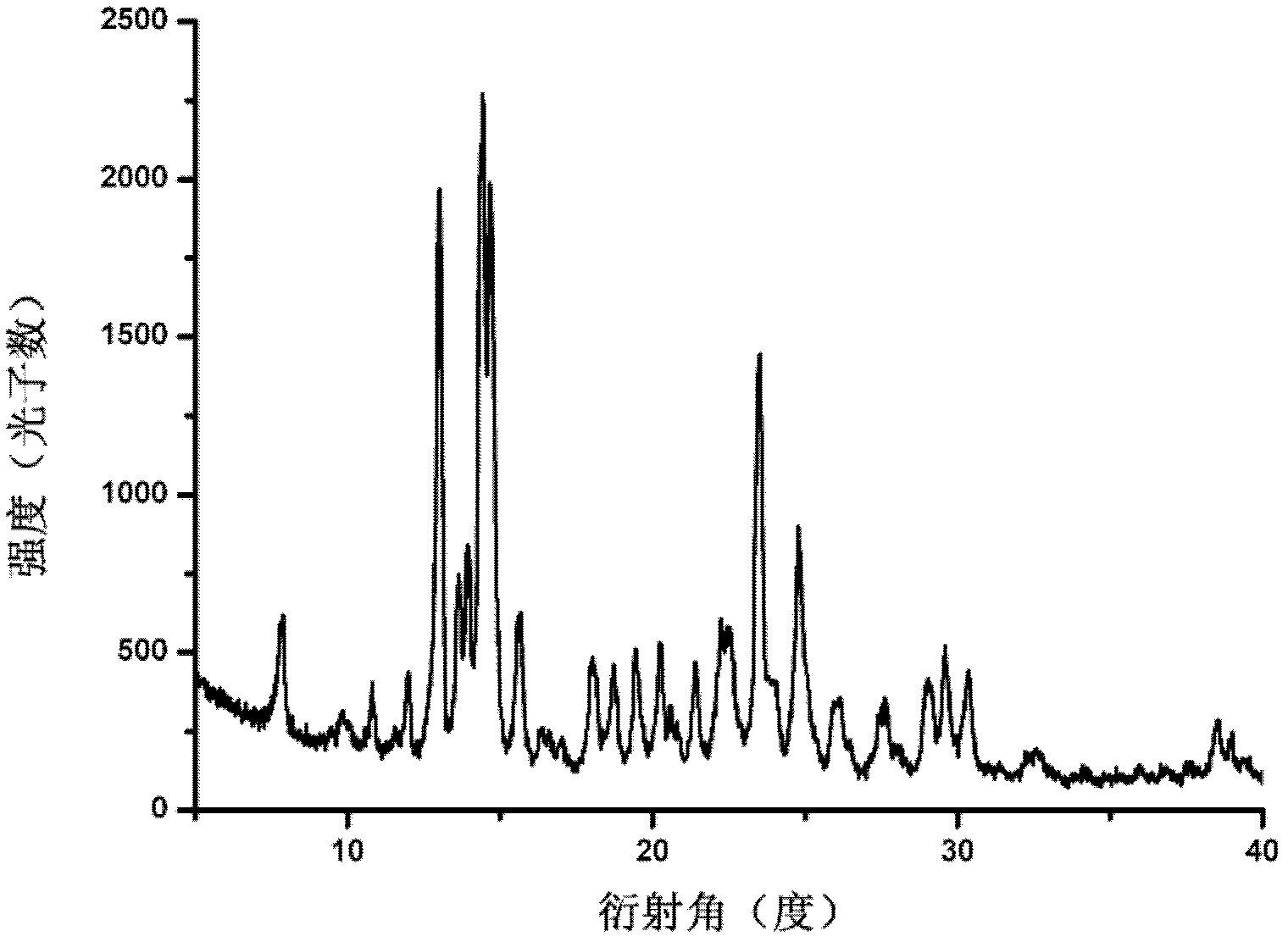

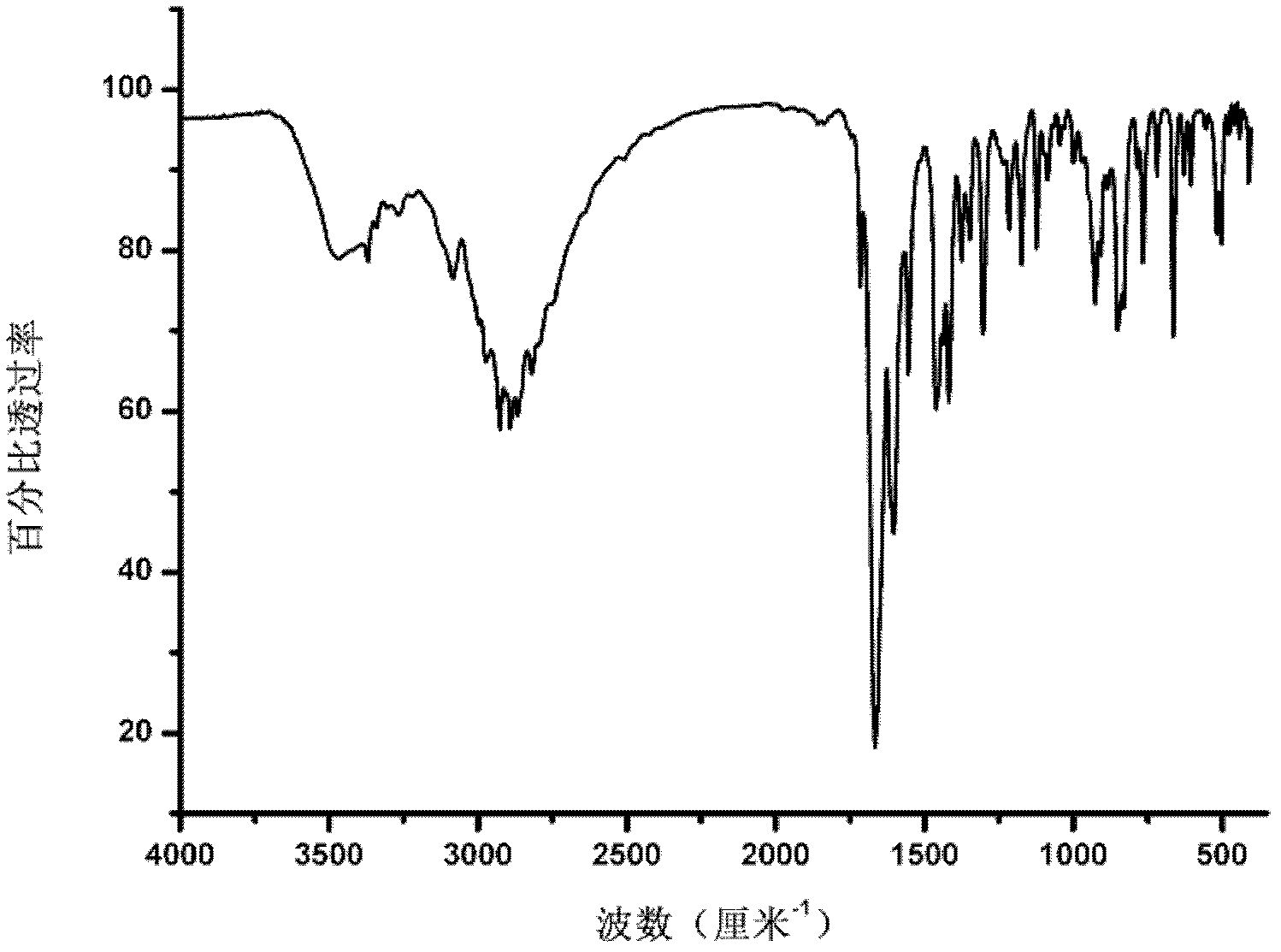

[0056] Mix 50 mg of huperzine A raw material (amorphous) with 1 ml of acetone, heat to 50° C. and keep stirring at 50° C. for 3 days, and filter to obtain a white solid. After evaporating the solvent at room temperature, the white solid was dried under reduced pressure with an oil pump for 12 hours to obtain a crystalline powder, which was determined by X-ray powder diffraction, showing that the obtained crystal form was Form I. The specific peak positions are shown in Table 1 below.

[0057] Table 1: X-ray powder diffraction data of Huperzine A crystal form I in Example 1 of the present invention

[0058]

[0059]

[0060] Other tests were carried out on the obtained sample, and the obtained DSC thermal spectrum, infrared spectrum and Raman spectrum were as follows: Figure 1b , 1c , 1d shown.

Embodiment 2

[0061] Example 2: Preparation of huperzine A crystal form II.

[0062] Put 25 mg of huperzine A crystal form I in an oven at 125 degrees Celsius and heat for 2 hours to obtain a crystalline powder, which was determined by X-ray powder diffraction to show that the obtained crystal form was crystal form II. The specific peak positions are shown in Table 2 below.

[0063] Table 2: X-ray powder diffraction data of Huperzine A crystal form II in Example 2 of the present invention

[0064]

[0065]

[0066] Other tests were carried out on the obtained sample, and the obtained DSC thermal spectrum, infrared spectrum and Raman spectrum were as follows: Figure 2b , 2c , as shown in 2d.

Embodiment 3

[0067] Example 3: Preparation of huperzine A crystal form III.

[0068] Mix 50 mg of huperzine A crystalline form I with 1 ml of acetonitrile, heat to 50° C. and keep stirring at 50° C. for 2 days, and filter to obtain a white solid. After evaporating the solvent at room temperature, the white solid was placed in a vacuum drying oven at 100°C, and dried for 24 hours under vacuum with an oil pump to obtain a crystalline powder, which was determined by X-ray powder diffraction, showing that the obtained crystal form was crystal Type III. The specific peak positions are shown in Table 3 below.

[0069] Table 3: X-ray powder diffraction data of Huperzine A crystal form III in Example 3 of the present invention

[0070]

[0071] Other tests were carried out on the obtained sample, and the obtained DSC thermal spectrum, infrared spectrum and Raman spectrum were as follows: Figure 3b , 3c , 3d shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com