Treatment device for emission reduction control over nitrogen oxide in flue gas

A nitrogen oxide and treatment device technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as inconvenient maintenance and replacement, damage to follow-up equipment in the flue, and short service life of nozzles, etc., to prevent ammonia Excessive gas leakage, reduced operation and maintenance costs, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

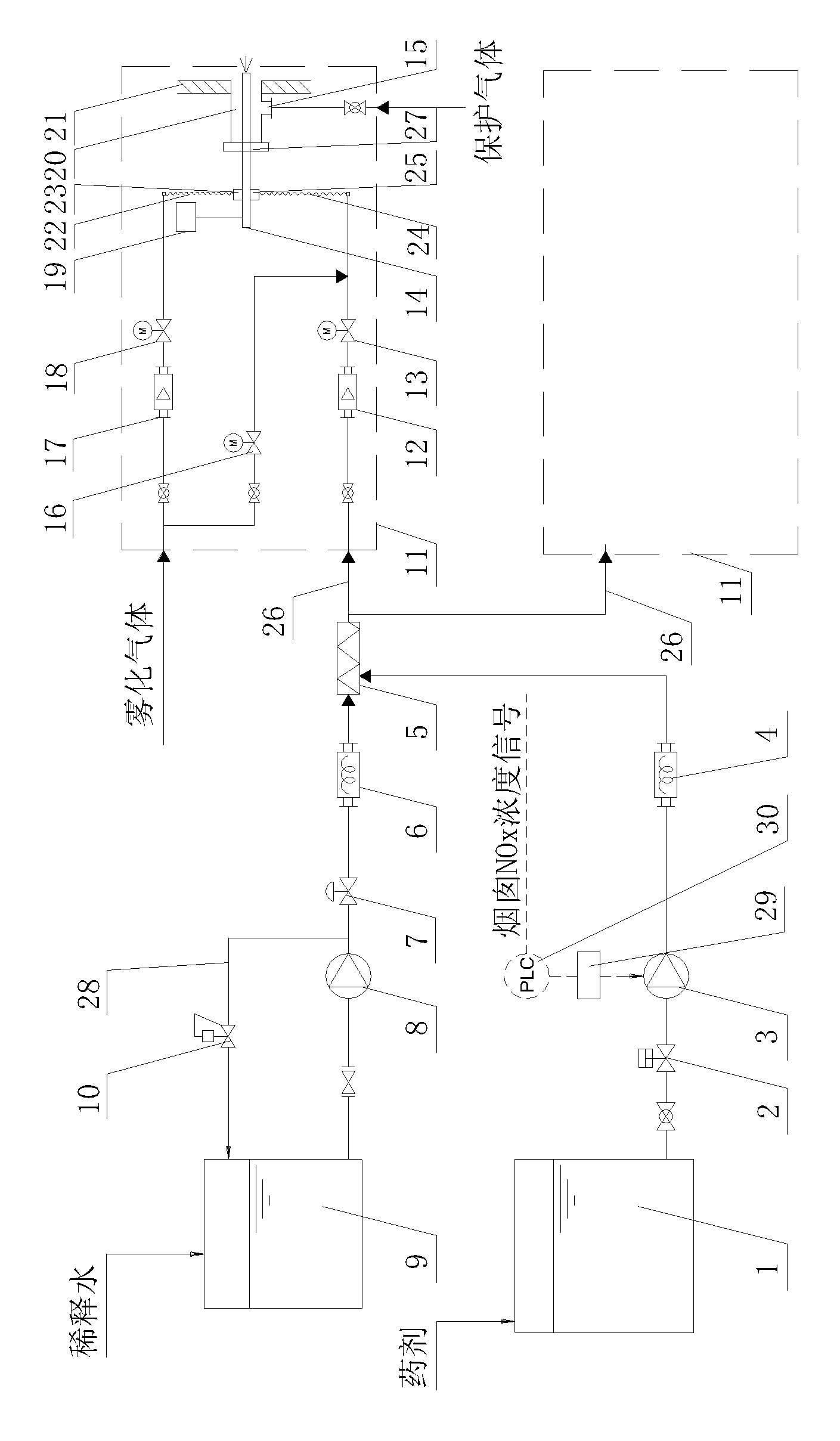

[0016] See figure 1 , which includes a medicament storage tank 1, a dilution water tank 9, a medicament delivery unit, a dilution water delivery unit, a pipeline mixer 5, a medicament injection unit 11, and a flue wall 21, and the medicament delivery unit includes a medicament storage tank outlet switch valve 2, a medicament The jet pump 3, the electromagnetic flowmeter 4, the outlet of the medicine storage tank 1 is connected to the outlet switch valve 2 of the medicine storage tank, the medicine injection pump 3, and the electromagnetic flowmeter 4 through pipelines, and then connected to an inlet of the pipeline mixer 5, and the medicine injection pump 3. Connect the frequency converter 29, the frequency converter 29 is connected to the PLC module 30, and the nitrogen oxide emission concentration signal in the chimney is connected to the input terminal of the PLC module 30; the dilution water delivery unit includes a water pump 8, a regulating valve 7, an electromagnetic flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com