Intermediate film for laminated glass, and laminated glass

A technology of laminated glass and interlayer film, applied in the direction of glass/slag layered products, layered products, synthetic resin layered products, etc., can solve the problem of not being able to fully absorb near-infrared rays, and achieve high heat insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

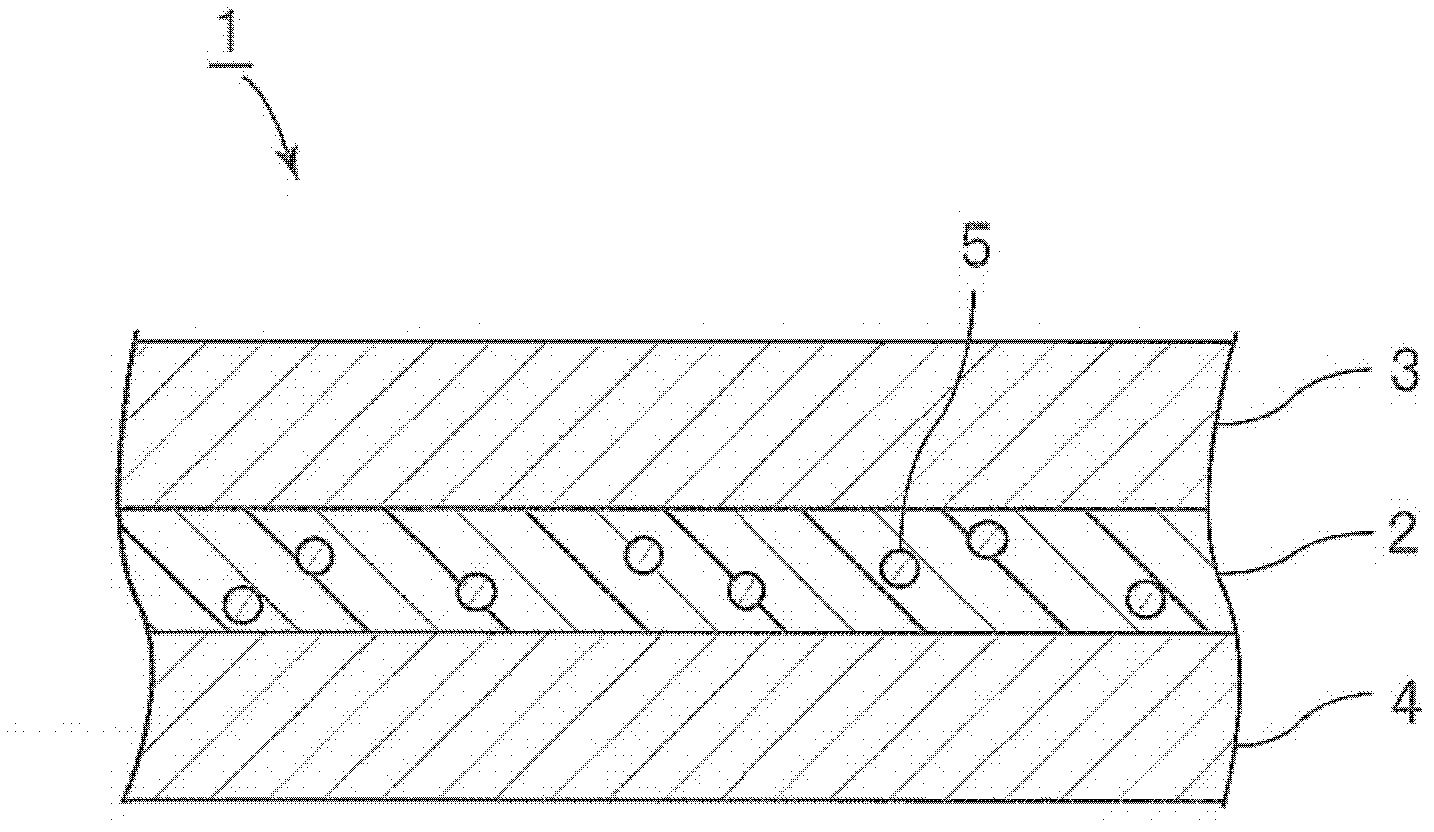

Method used

Image

Examples

Embodiment 1

[0103] (1) Preparation of dispersion

[0104] 40 parts by weight of triethylene glycol di-2-ethylhexanoate (3GO), 0.98 parts by weight of ITO particles (manufactured by Mitsubishi Materials), and naphthalocyanine compound (copper naphthalocyanine compound, manufactured by Fujifilm) "FF IRSORB203") 0.0182 parts by weight were mixed, and after adding a phosphate compound as a dispersant, the mixture was mixed with a horizontal bead mill to obtain a mixed liquid. Then, 0.1 parts by weight of acetylacetone was added to the mixed liquid under stirring to prepare a dispersion liquid. Among them, the content of the phosphate compound is adjusted to 1 / 10 of the content of the heat-insulating particles.

[0105] (2) Production of interlayer film for laminated glass

[0106] With respect to 100 parts by weight of polyvinyl butyral resin (degree of butyralization 68.5 mol%, hydroxyl content 30.5 mol%), the entire amount of the obtained dispersion is added, and the mixture is sufficiently melt...

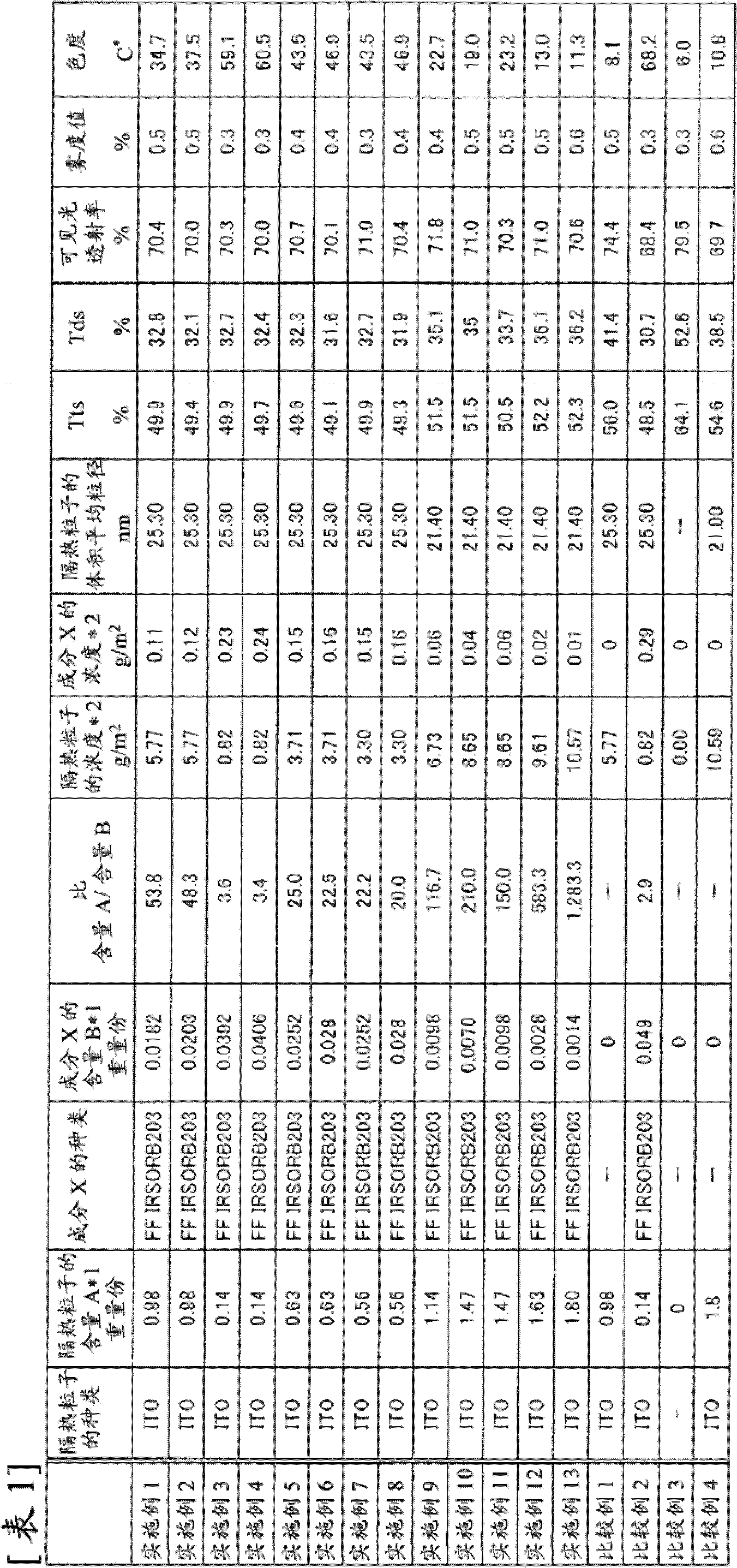

Embodiment 2~13 and comparative example 1~4

[0110] Like Example 1, the dispersion liquid, the interlayer film for laminated glass, and the laminated glass were produced, except that the composition (mixing amount) of the interlayer film for laminated glass was changed as shown in Table 1 below. In addition, in Examples 2-13 and Comparative Examples 1-2, 4, the content of a phosphoric acid ester compound was adjusted to 1 / 10 of the content of heat insulating particles. In Comparative Example 3, no phosphate compound was used.

[0111] (Evaluation of Examples 1 to 13 and Comparative Examples 1 to 4)

[0112] (1) Measurement of Tts and Tds (Solar Direct Transmittance)

[0113] The aforementioned Tts and the aforementioned Tds of the obtained laminated glass were measured according to the measuring method prescribed by the aforementioned Cool Cars Standards, which is scheduled to be introduced. Specifically, the above-mentioned Tts and the above-mentioned Tds were measured with a spectrophotometer ("U-4100" manufactured by Hitac...

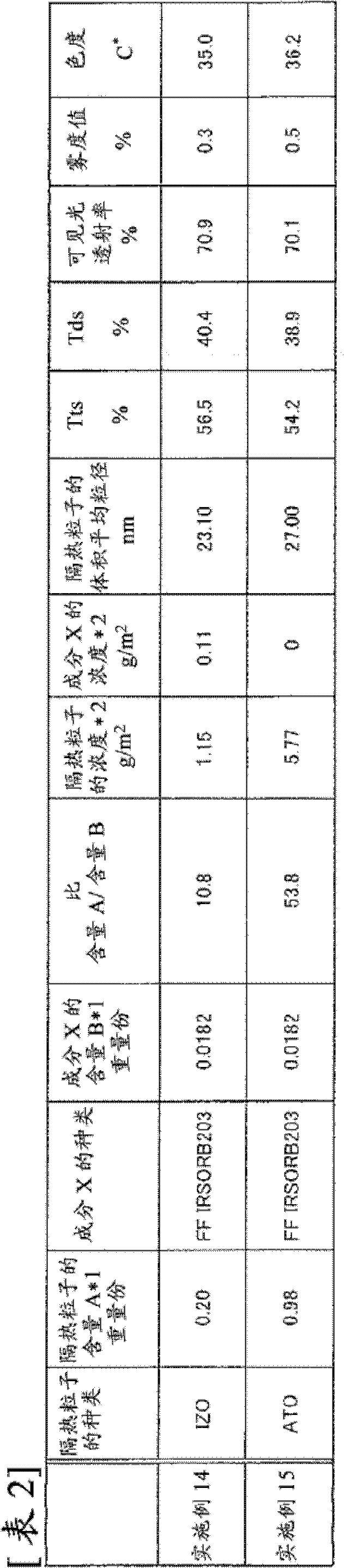

Embodiment 14

[0124] The dispersion, the interlayer film for laminated glass, and the laminated glass were produced as in Example 1. The difference is that the ITO particles (manufactured by Mitsubishi Materials Co., Ltd.) are changed to IZO particles, and the composition of the interlayer film for laminated glass (mixing amount) The changes shown in Table 1 below were made. In addition, in Example 14, the content of the phosphoric acid ester compound was adjusted to 1 / 10 of the content of the heat insulating particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com