Novel dead-zone effect compensation method of AC servo inverter

An AC servo, dead zone effect technology, applied in the direction of converting AC power input to DC power output, controlling electromechanical brakes, output power conversion devices, etc., can solve the problem of unsatisfactory dead zone compensation, aggravating grid harmonic pollution, reducing control System efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Now in conjunction with accompanying drawing, patent of the present invention is described in detail as follows:

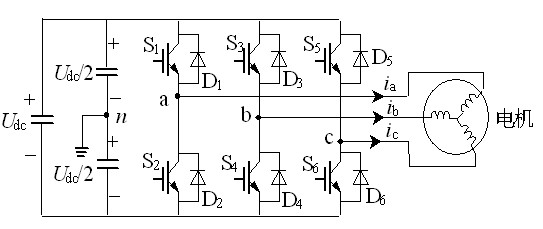

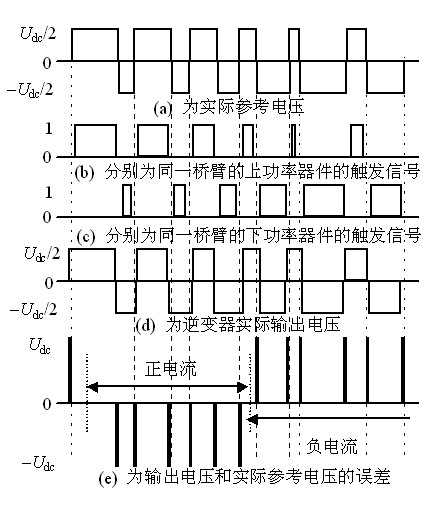

[0049] Step 1. Determine the generation of inverter dead zone

[0050] Such as figure 1 As shown, it is a voltage-type PWM inverter circuit, including three bridge arms, which are composed of 6 IGBTs, and each bridge arm is composed of a controllable device (S 1- S 6 ) and an antiparallel diode (D 1 -D 6 )composition. The different conduction modes of the six switches of the three-phase AC inverter bridge generate different voltage basic vectors, and any vector is synthesized through vector synthesis, and the magnitude of the vector is determined by the different conduction times. Let a=0, which means that in the first group of bridge arms: the upper bridge arm is cut off, and the lower bridge arm is turned on; a=1, means that in the first group of bridge arms: the upper bridge arm is turned on, and the lower bridge arm is turned off, similarly The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com