Spark gap

A technology for spark gaps and gaps, which is applied in the direction of spark gaps, spark gap components, circuits dedicated to spark gaps, etc., can solve the problems of long delay, high ignition discharge voltage, etc., to save costs, improve stability and reliability , Conducive to the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

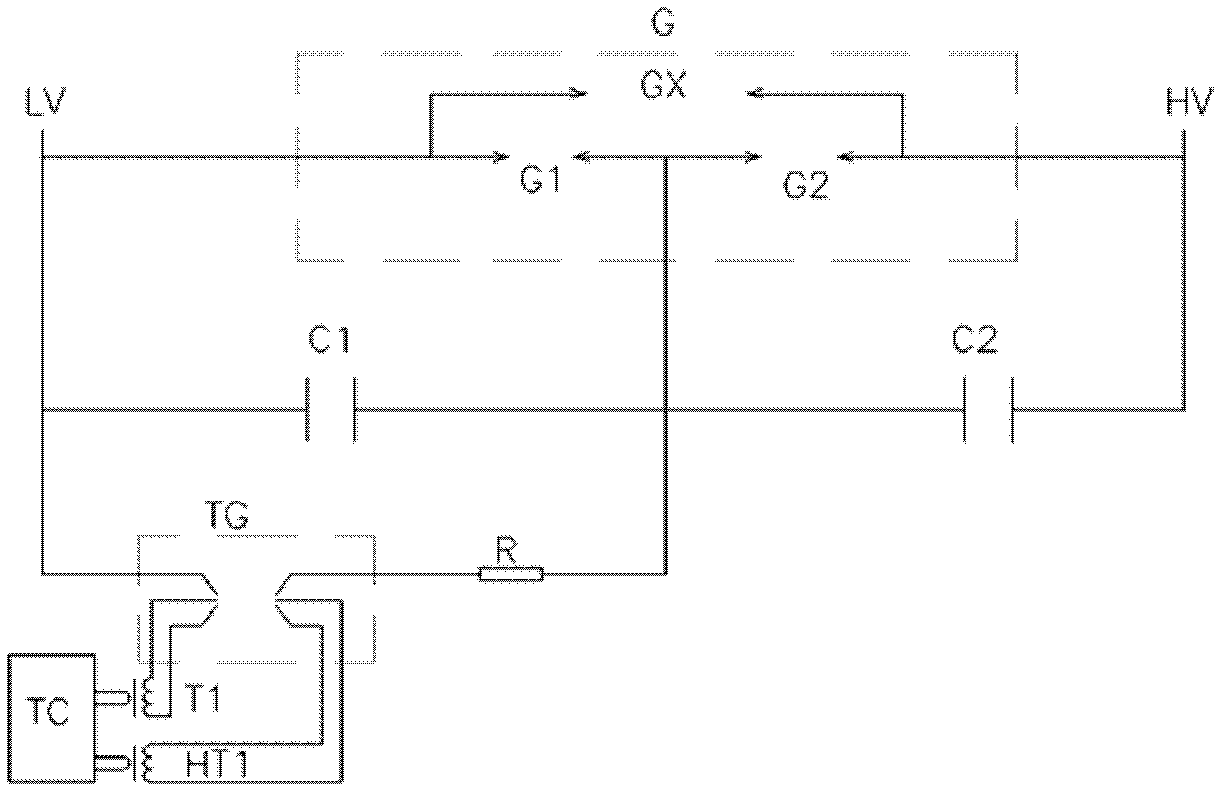

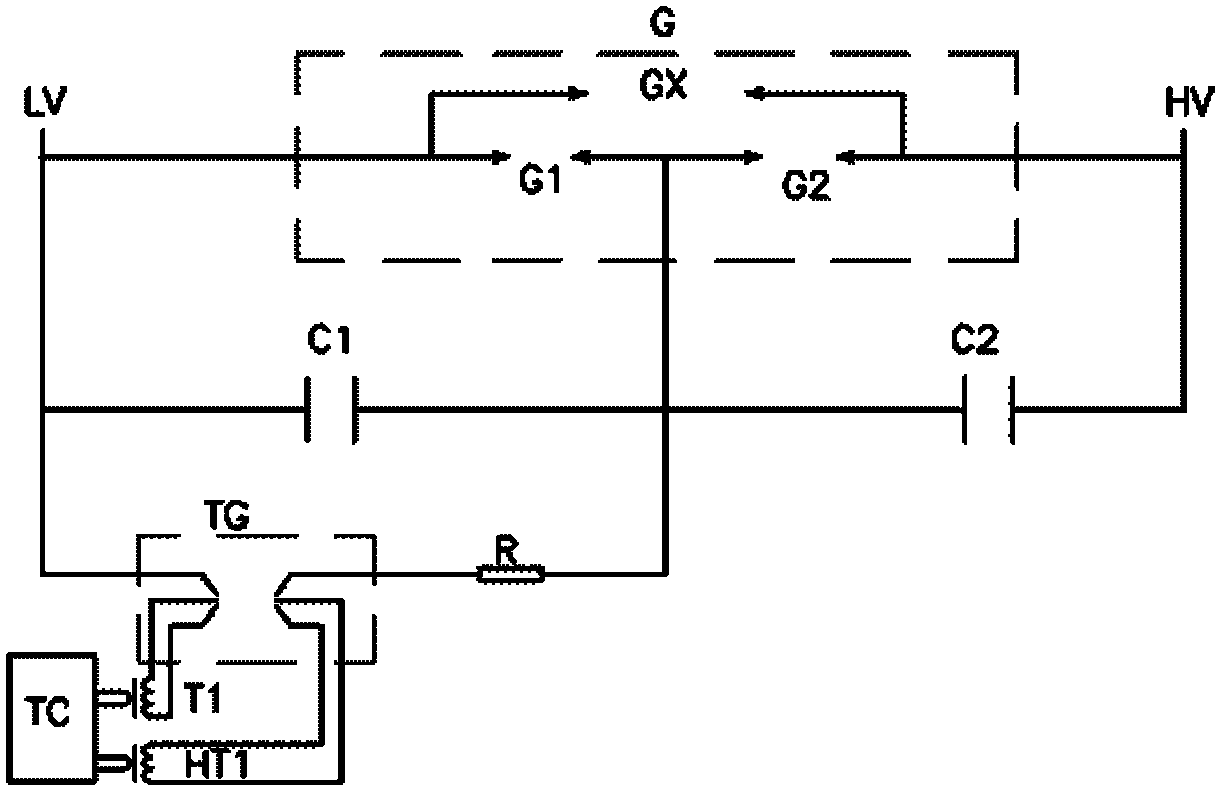

[0022] A spark gap with a single gap structure, the spark gap includes a self-discharging main gap G and a gap trigger system, the self-discharging main gap G includes a gap shell, flashover gaps G1, G2 and a freewheeling gap GX, the The flashover gaps G1 and G2 are connected in parallel with the freewheeling gap GX after being connected in series; the two ends of the spark gap are respectively connected with the high voltage end and the low voltage end; the gap trigger system is connected in parallel with the flashover gap G1 connected with the low voltage end.

[0023] The flashover gaps G1 and G2 are respectively equalized by voltage equalizing capacitors C1 and C2, the voltage equalizing capacitor C1 is connected in parallel with the flashover gap G1, and the voltage equalizing capacitor C2 is connected in parallel with the flashover gap G2.

[0024] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com