Lithium ion battery and anode and preparation method thereof

A technology for lithium-ion batteries and anode sheets, applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., to achieve the effect of simple process and elimination of deformation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation of anode sheet:

[0052] Take 0.575kg EC, dry mix it with 1.916kg FSNC graphite at 60°C for 2h, then add 40gSBR, 24g CMC, 20g Super-P and 2.4kg water respectively, stir evenly at 60°C, then coat and keep the coating machine The head temperature is 60°C and the oven temperature is 110°C constant; the coated membrane is placed in an environment of 0°C for 4 hours, and after the membrane is cooled and the EC is completely solidified, it is cold-pressed at 0°C to prepare An anode coated membrane with EC coated on the surface of graphite particles was obtained (the mass ratio of EC to graphite was 30%).

[0053] Preparation of cathode sheet:

[0054] Lithium cobalt oxide (LiCoO 2 ) is a cathode active material, and its weight content is 96%; with polyvinylidene fluoride (PVDF) as a binding agent, its weight content is 2%; with carbon black as a conductive agent, its weight content is 2%; the above-mentioned materials Add it into N-methylpyrrolidone (NMP) and s...

Embodiment 2

[0060] Different from Example 1 is the preparation of the anode sheet and the preparation of the electrolyte, wherein the preparation of the anode sheet is:

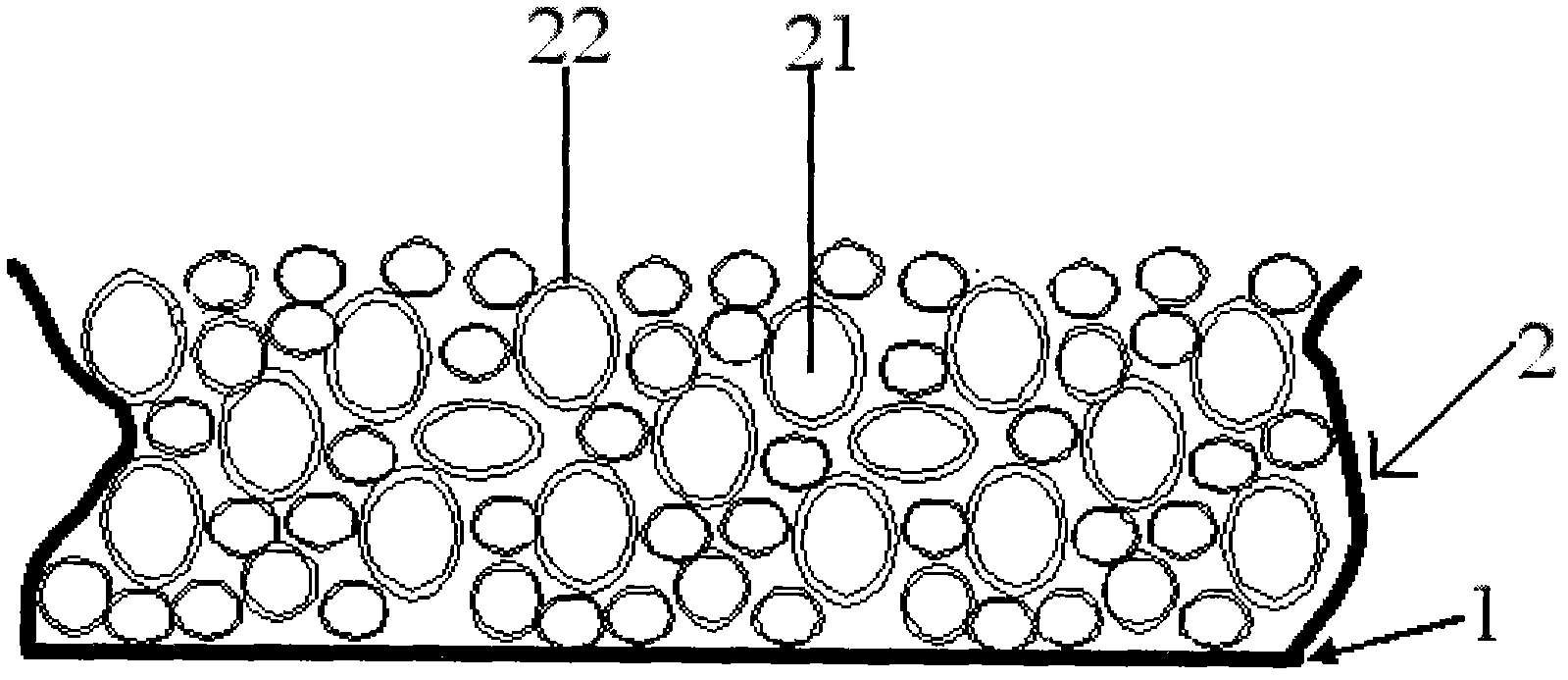

[0061] Be graphite by each component distribution ratio: SBR: CMC: Super-P=95.8: 2.4: 0.8: 1.0 relation weighing material, after stirring at 45 ℃, obtain the anode slurry 2kg that solid content is 48%; Weigh 0.183kgEC, add to the anode slurry, continue to stir at constant temperature until the components are evenly mixed, keep the temperature of the coating machine head at 45°C, and the oven temperature at 90°C for coating, and the coating weight is 160mg / 1540.25mm 2 , and then put the diaphragm at 20°C for 6 hours. After the diaphragm was cooled and the EC was completely solidified, it was cold-pressed at 20°C to obtain an anode sheet with a thickness of 128 μm after cold pressing ((the mass of EC and graphite Ratio is 20%))), the structural representation of the anode sheet is as figure 2 As shown, the anode sheet in...

Embodiment 3

[0069] Different from Example 1 is the preparation of the anode sheet and the preparation of the electrolyte, wherein the preparation of the anode sheet is:

[0070] Take 0.005kg of EC, 1.916kg of graphite, 40g of SBR, 24g of CMC, 20g of Super-P and 2.4kg of water, stir evenly at 40°C and then coat and keep the temperature of the coating machine head at 40°C and the temperature of the oven at 60°C Constant; place the coated membrane in a 30°C environment for 10 hours, and then cold press it at 30°C after the membrane is cooled and the EC is completely solidified to prepare an anode sheet coated with EC on the surface of graphite particles (The mass of EC is 0.26% of the total mass of graphite).

[0071] Electrolyte preparation:

[0072] Mix ethylene carbonate (EC), propylene carbonate (PC) and dimethyl carbonate (DMC) according to the mass ratio of 29.74:30:40 to obtain a mixed solvent, and then add lithium hexafluorophosphate (LiPF 6 ), so that LiPF 6 The concentration is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com