Automatic crack detection and alarm system and method for vane of wind driven generator

A wind turbine, blade crack technology, applied in signal transmission systems, measuring devices, instruments, etc., can solve the problems of high labor intensity, low efficiency, high cost, etc., and achieve a high degree of automation, broad application prospects, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

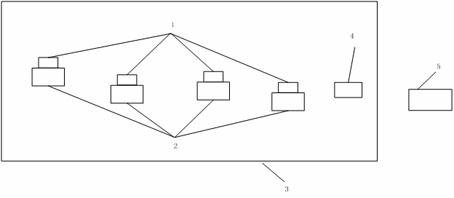

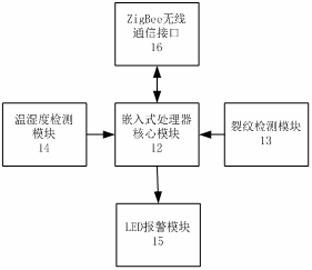

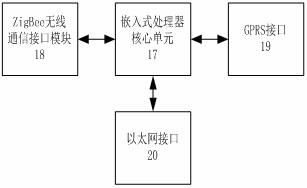

[0020] to combine figure 1 , figure 2 , a kind of wind generator blade crack automatic detection alarm system of the present invention, comprises several detection devices 1 and control equipment 4, and described detection device 1 is installed on the blade of wind turbine 2, and this detection device 1 and control equipment 4 pass ZigBee The wireless communication mode is connected, and the result of detection is transmitted to control equipment 4; Described detection device 1 comprises embedded processor core module 12, some crack detection modules 13, temperature and humidity detection module 14, LED alarm module 15 and ZigBee wireless communication Interface 16, the crack detection module 13 is connected with the embedded processor core module 12, and the detected blade state signal is transmitted to the embedded processor core module 12, and the temperature and humidity detection module 14 is connected with the embedded processor core module 12 Connect, the detected tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com