Measurement method for oil-water ash content in gas

A technology of gas, oil and water, applied in the field of gas detection, can solve the problems of inability to measure industrial gas containing a large amount of water, inability to measure gas oil content and ash content at the same time, narrow application range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

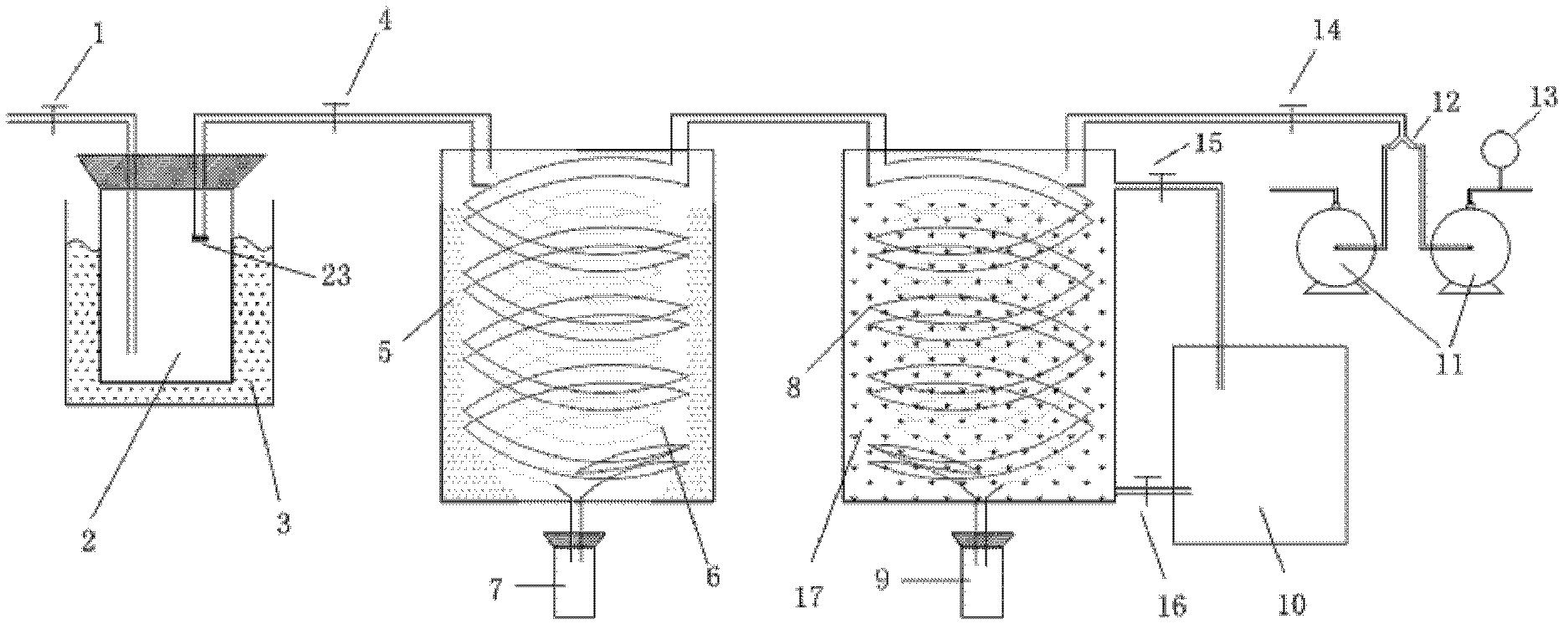

[0080] This embodiment provides a condensing device for measuring oil, water and ash content in gas, its structure is as follows figure 1 shown. The condensing device for determining the oil-water ash content in gas includes:

[0081] The first receiving bottle 2, the first ice-water mixing container 3, the second ice-water mixing container 5, the first condensing coil 6, the second receiving bottle 7, the second condensing coil 8, the third receiving bottle 9, cryogenic cooling Container 17, circulating cooling pump 10, wet gas flowmeter 11, barometer and thermometer 13, wherein:

[0082] The first receiving bottle 2 is provided with an input pipe, which is provided with a first valve 1, the first receiving bottle 2 communicates with the inlet of the first condensing coil 6 through a pipeline, and the first receiving bottle 2 is located at the first ice In the water mixing container 3;

[0083] The pipeline between the first receiving bottle 2 and the first condensing coi...

Embodiment 2

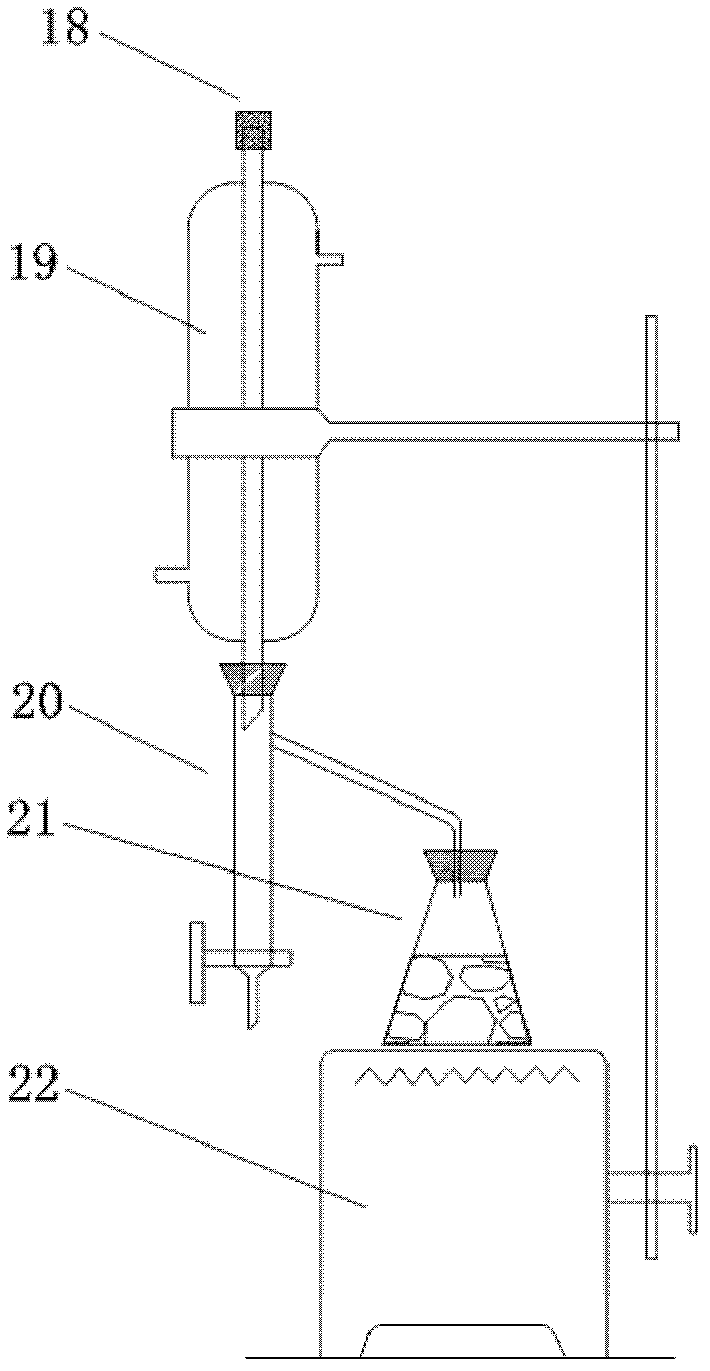

[0091] This embodiment provides a water separation device for measuring oil-water ash content in gas, its structure is as follows figure 2 shown. The water separating device for determining the oil-water ash content in gas includes:

[0092] Glass condensing tube 19, moisture measuring tube 20, Erlenmeyer flask 21 and heating furnace 22, wherein, glass condensing tube 19 is located at the top of moisture measuring tube 20, and the lower opening of the intermediate pipe of glass condensing tube 29 is connected to moisture measuring tube 20 Among them, the top of the intermediate pipe is sealed by a cotton ball 18, the Erlenmeyer flask 21 is arranged above the heating furnace 22, and the Erlenmeyer flask 21 communicates with the moisture measuring tube 20. The above-mentioned Erlenmeyer flask 21 is a ground-mouthed Erlenmeyer flask made of quartz.

Embodiment 3

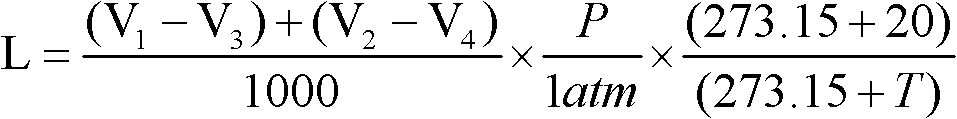

[0094] This embodiment provides a method for measuring the oil, water and ash content of gas gas, which uses the condensing device for measuring the oil, water and ash content in gas gas of Example 1 and the water separator for measuring the oil, water and ash content in gas gas of Example 2. The method for measuring the content of oil, moisture and ash in gas, it may further comprise the steps:

[0095] 1. Gas condensation process:

[0096] Make the gas to be tested pass through the first valve 1 at 0-5°C and enter the first receiving bottle 2 for preliminary cooling;

[0097] Then, after the gas passes through the filter 23, it enters the first condensing coil 6 with a temperature of 0-5°C for secondary cooling, so that the mixture of oil, water and ash flows into the second receiving bottle 7;

[0098] Let the secondary cooled gas enter the second condensation coil 8 with a temperature of -10°C to -25°C for deep cooling, so that the mixture of oil, water and ash enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com