Method and apparatus for performing film thickness measurements using white light scanning interferometry

A technology of interferometry and interferometer, which is applied in the direction of measuring devices, optical devices, instruments, etc., and can solve problems such as slow measurement speed applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

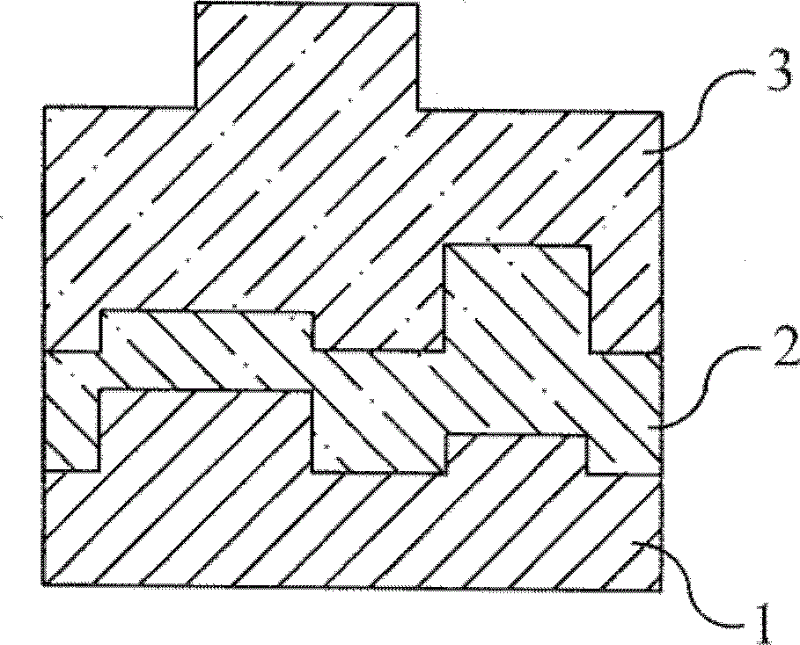

[0054] Figure 2A A cross-sectional view is shown of a non-permeable substrate 1 on which a semi-transparent membrane 2 is provided. The invention aims at measuring the thickness of the film 2 initially independently of the height profile of the substrate 1 , but in a special embodiment also together with the height profile.

[0055] also, Figure 2B show with Figure 2A Similar view where the second semi-permeable layer 3 has been applied on the first semi-permeable layer 2 . The refractive index of the second layer 3 is different from the refractive index of the first permeable layer 2 .

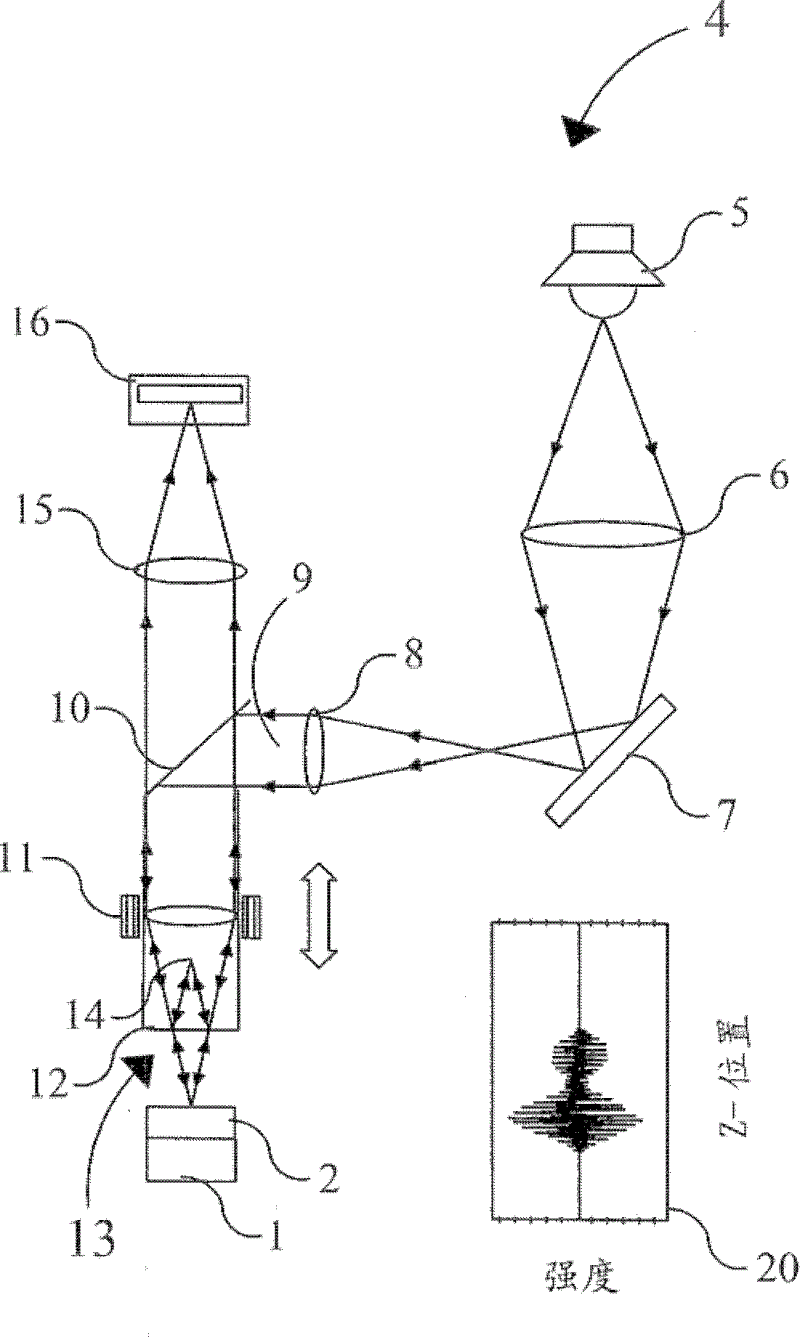

[0056] figure 1 The entire Mirau-type interferometer denoted by 4 is drawn. This interferometer 4 comprises a light source 5 suitable for generating white light, a first lens 6 , a first mirror 7 and a second lens 8 , these units being suitable for generating a parallel light beam 9 . The parallel light beam 9 can also be generated by other components. The parallel beam 9 is reflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com